Electric-heating anti-icing coating and preparation method thereof

A heating coating and electric heating technology, which is applied in coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of high energy consumption, uneven heating of resistance wires, low heating and heat transfer efficiency, etc., and achieve good flexibility , The effect of low energy utilization rate and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

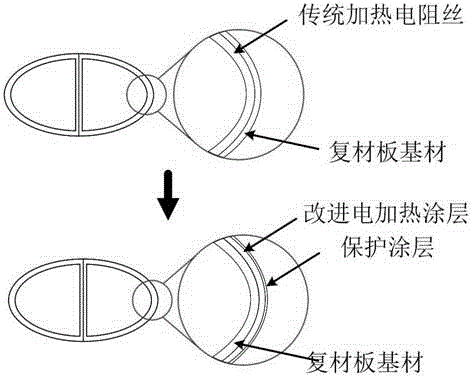

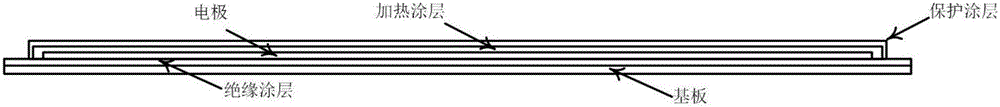

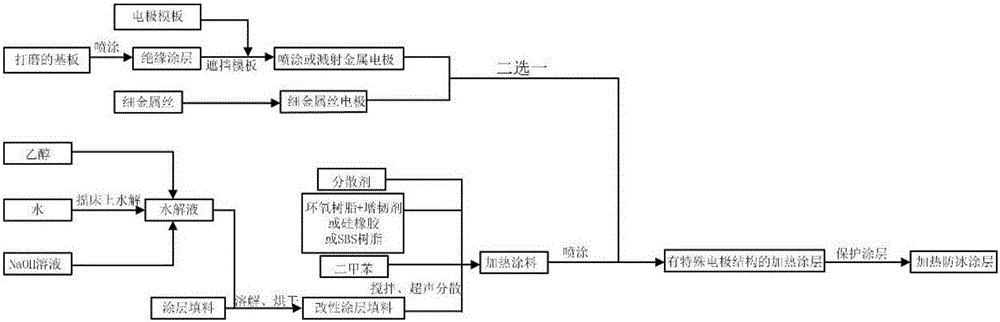

[0041] (1) A kind of electric heating anti-icing coating of the present invention, see figure 2 As shown, its structure is as follows: firstly, a layer of insulating coating is sprayed on the substrate to play the role of insulation and heat insulation from the substrate; secondly, a new type of electrode is made on the insulating coating to make the heating more uniform; thirdly , spray electric heating paint on the electrode; finally spray a protective coating on the outermost layer to play a protective role.

[0042] In the present invention, the heating coating is sprayed on the outer surface of the substrate, which is closer to the ice accumulation layer. And under the action of the thermal insulation coating, most of the heat is transferred outward for heating and deicing, which greatly improves the heating efficiency and reduces the temperature resistance requirements of the material itself, which meets the temperature resistance requirements of composite materials suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com