Preparation method and application of nitrogen-doped graphene quantum dots

A graphene quantum dots, nitrogen protection technology, applied in chemical instruments and methods, fluorescence/phosphorescence, luminescent materials, etc., can solve the problems of limiting the wide application of nitrogen-doped graphene quantum dots, troublesome and time-consuming operations, and increased preparation costs. , to achieve the effect of low raw material price, simple equipment and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

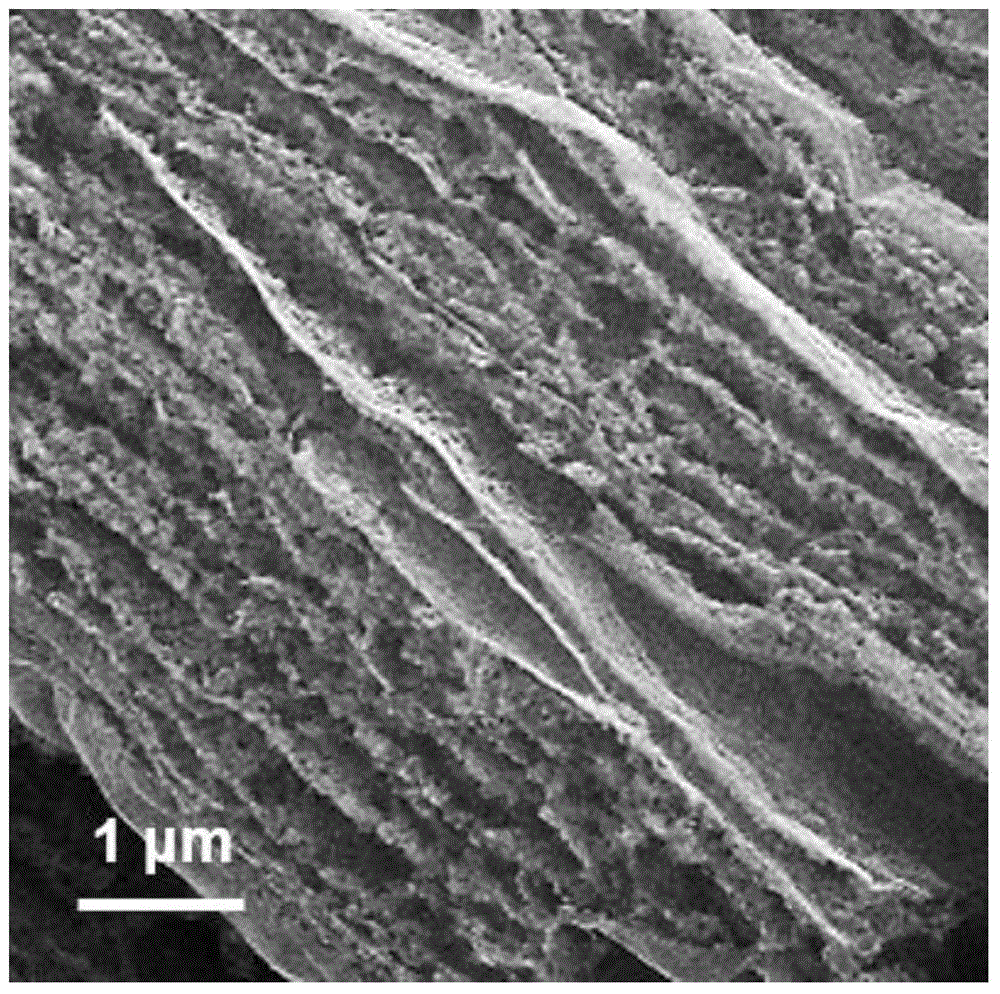

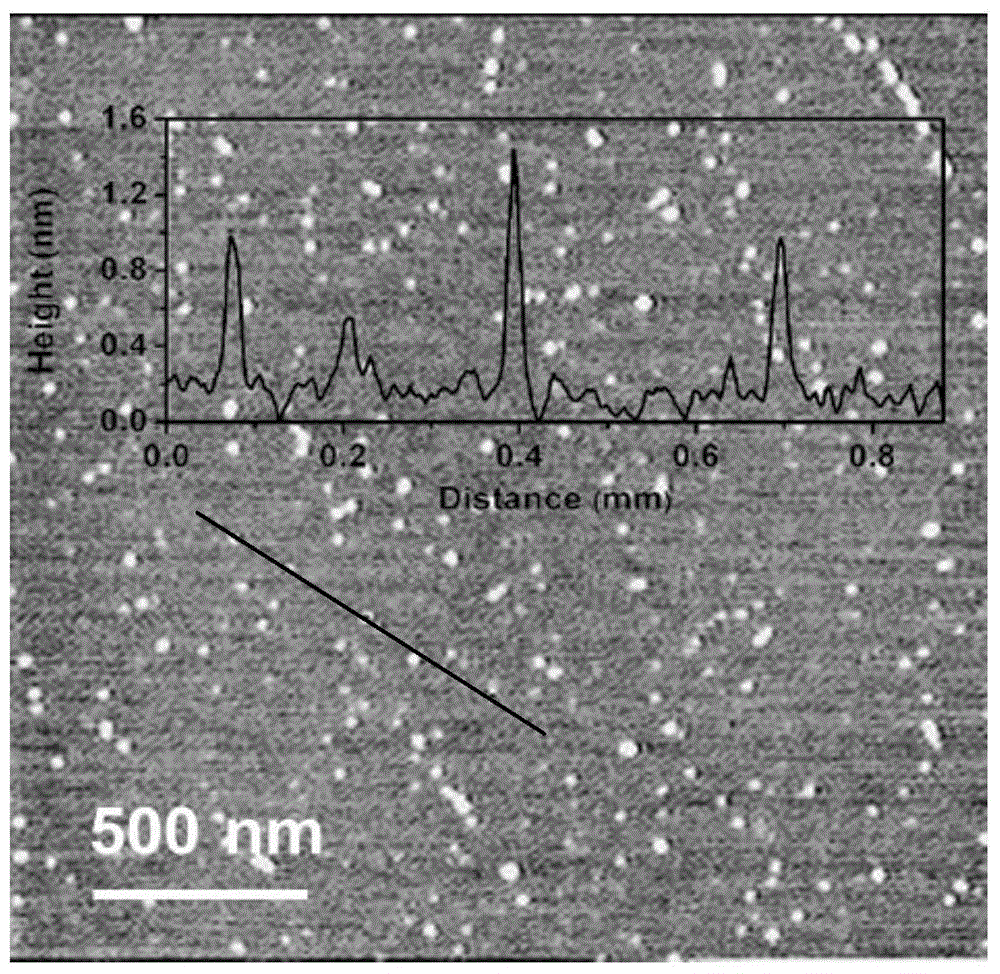

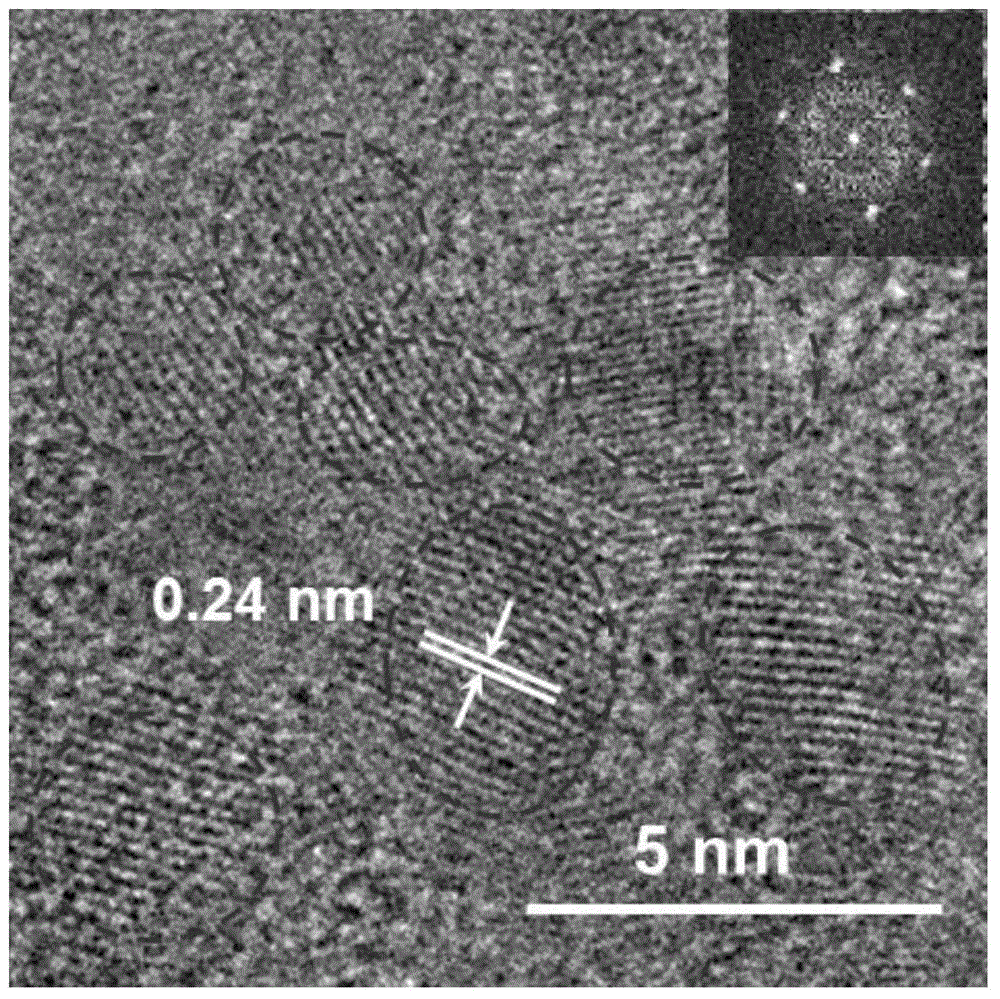

[0034] Put 0.5g TATB in a muffle furnace under nitrogen protection, raise the temperature to 750°C at a heating rate of 2°C / min, keep it warm for 20min, and then cool down to room temperature naturally to obtain a polymer of nitrogen-doped graphene quantum dots , take the polymer 0.1g of the nitrogen-doped graphene quantum dots and place it in 18.75ml concentrated H 2 SO 4 and 5.25ml concentrated HNO 3 In the mixed acid with ultrasonic power of 300W, ultrasonic stripping was carried out for 2h, and then the stirring speed was set at 100°C to be 600r / min and stirred for 24h to obtain the solution of nitrogen-doped graphene quantum dots, and the solution of nitrogen-doped graphene quantum dots was added 50ml of water and sodium carbonate were used to adjust the pH value of the solution to 7, and finally the solution was dialyzed to obtain nitrogen-doped graphene quantum dots.

Embodiment 2

[0036] Place 0.5g TATB in a muffle furnace under the protection of nitrogen, raise the temperature to 500°C at a heating rate of 5°C / min, keep warm for 240min, and then cool down to room temperature naturally to obtain a polymer of nitrogen-doped graphene quantum dots. Get the polymer 0.1g of this nitrogen-doped graphene quantum dot and place in 18.75ml concentrated H 2 SO 4 and 5.25ml concentrated HNO 3 In the mixed acid with ultrasonic power of 400W, ultrasonic stripping was carried out for 2h, and then the stirring speed was set at 100°C to be 500r / min and stirred for 24h to obtain the solution of nitrogen-doped graphene quantum dots, and the solution of nitrogen-doped graphene quantum dots was added 50ml of water and sodium carbonate were used to adjust the pH value of the solution to 7, and finally the solution was dialyzed to obtain nitrogen-doped graphene quantum dots.

Embodiment 3

[0038] Place 0.5g TATB in a muffle furnace under nitrogen protection, raise the temperature to 900°C at a heating rate of 10°C / min, keep it warm for 40min, and then cool down to room temperature naturally to obtain a polymer of nitrogen-doped graphene quantum dots. Get the polymer 0.1g of this nitrogen-doped graphene quantum dot and place in 18.75ml concentrated H 2 SO 4 and 5.25ml concentrated HNO 3 In the mixed acid with ultrasonic power of 400W, the ultrasonic stripping was carried out for 2h, and then the stirring speed was set at 100°C to be 800r / min and stirred for 24h to obtain the solution of nitrogen-doped graphene quantum dots, and the solution of nitrogen-doped graphene quantum dots was added 50ml of water and sodium carbonate were used to adjust the pH value of the solution to 7, and finally the solution was dialyzed to obtain nitrogen-doped graphene quantum dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com