Method for coating and sensitivity reduction of HMX by using TATB

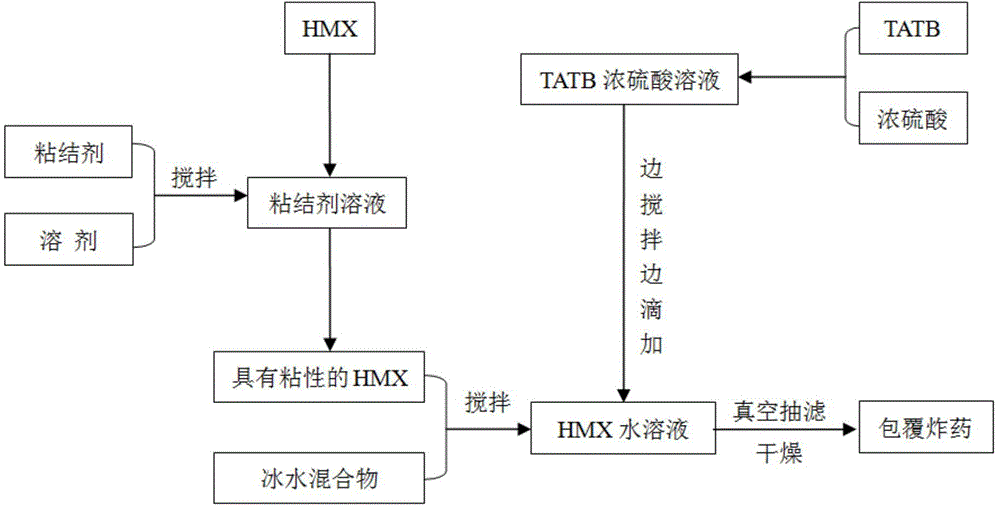

A technology for desensitization and coating, applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the problems of high cost, difficult to control the crystallization process, low solubility, etc., to prevent falling off and mild reaction conditions. , the effect of simple reaction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In the first step, add 0.09g Estane-5703, 6ml dichloroethane and 3g HMX into the beaker, stir magnetically at a speed of 200r / min at a constant temperature of 60°C for 30min until the solution is uniform, then vacuum filter and dry to obtain a surface Reactive and cohesive HMX;

[0036] In the second step, 0.53g TATB was dissolved in 1ml of concentrated sulfuric acid and stirred until dissolved to obtain a mixed solution of TATB concentrated sulfuric acid;

[0037] In the third step, add the surface-active and cohesive HMX3g and 200ml ice-water mixture prepared in the first step into the four-necked flask, and slowly drop the mixed solution of TATB concentrated sulfuric acid in the second step through the constant pressure dropping funnel. The four-necked flask was stirred rapidly for 1 h while adding dropwise to obtain a suspension;

[0038] The fourth step is to vacuum filter the suspension obtained in the third step, wash the filter cake with sodium carbonate until ...

Embodiment 2

[0042] In the first step, add 0.09g Estane-5703 and β-cyclodextrin, 9ml dichloroethane and 3g HMX into the beaker, stir magnetically at 200r / min at a constant temperature of 60°C for 30min until dissolved evenly, and then vacuum filter , drying to obtain surface active and cohesive HMX;

[0043] In the second step, 0.53g TATB was dissolved in 1ml of concentrated sulfuric acid and stirred until dissolved to obtain a mixed solution of TATB concentrated sulfuric acid;

[0044] In the third step, add the surface-active and cohesive HMX3g and 200ml ice-water mixture prepared in the first step into the four-necked flask, and slowly drop the mixed solution of TATB concentrated sulfuric acid in the second step through the constant pressure dropping funnel. The four-necked flask was stirred rapidly for 1 h while adding dropwise to obtain a suspension;

[0045] The fourth step is to vacuum filter the suspension obtained in the third step, wash the filter cake with sodium hydroxide unti...

Embodiment 3

[0048] In the first step, add 0.15g Estane-5703, 3.75ml mixed solution of dichloroethane and ethyl acetate and 3g HMX into the beaker, stir magnetically at 200r / min at a constant temperature of 60°C for 30min until dissolved evenly, and then vacuum HMX with surface activity and cohesiveness was obtained by suction filtration and drying;

[0049] In the second step, 0.53g TATB was dissolved in 1ml of concentrated sulfuric acid and stirred until dissolved to obtain a mixed solution of TATB concentrated sulfuric acid;

[0050]In the third step, add the surface-active and cohesive HMX3g and 200ml ice-water mixture prepared in the first step into the four-necked flask, and slowly drop the mixed solution of TATB concentrated sulfuric acid in the second step through the constant pressure dropping funnel. The four-necked flask was stirred rapidly for 1 h while adding dropwise to obtain a suspension;

[0051] The fourth step is to vacuum filter the suspension obtained in the third ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com