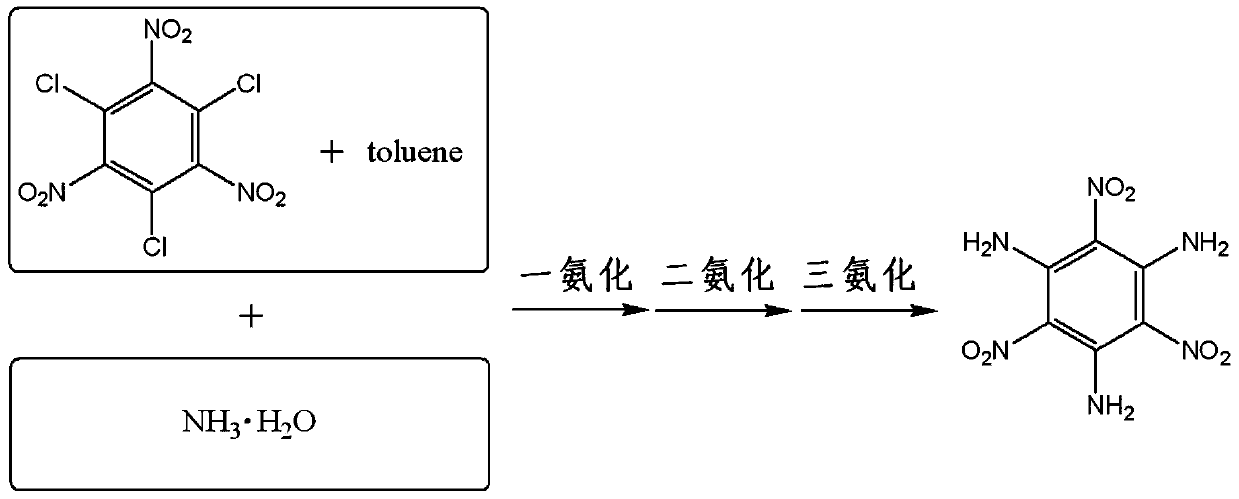

Channel synthesis method of m-triamino trinitrobenzene

A technology of triaminotrinitrobenzene and trichlorotrinitrobenzene is applied in the field of channel synthesis of m-triaminotrinitrobenzene to achieve the effects of promoting the reaction process, being easy to be continuous, and preventing seriousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

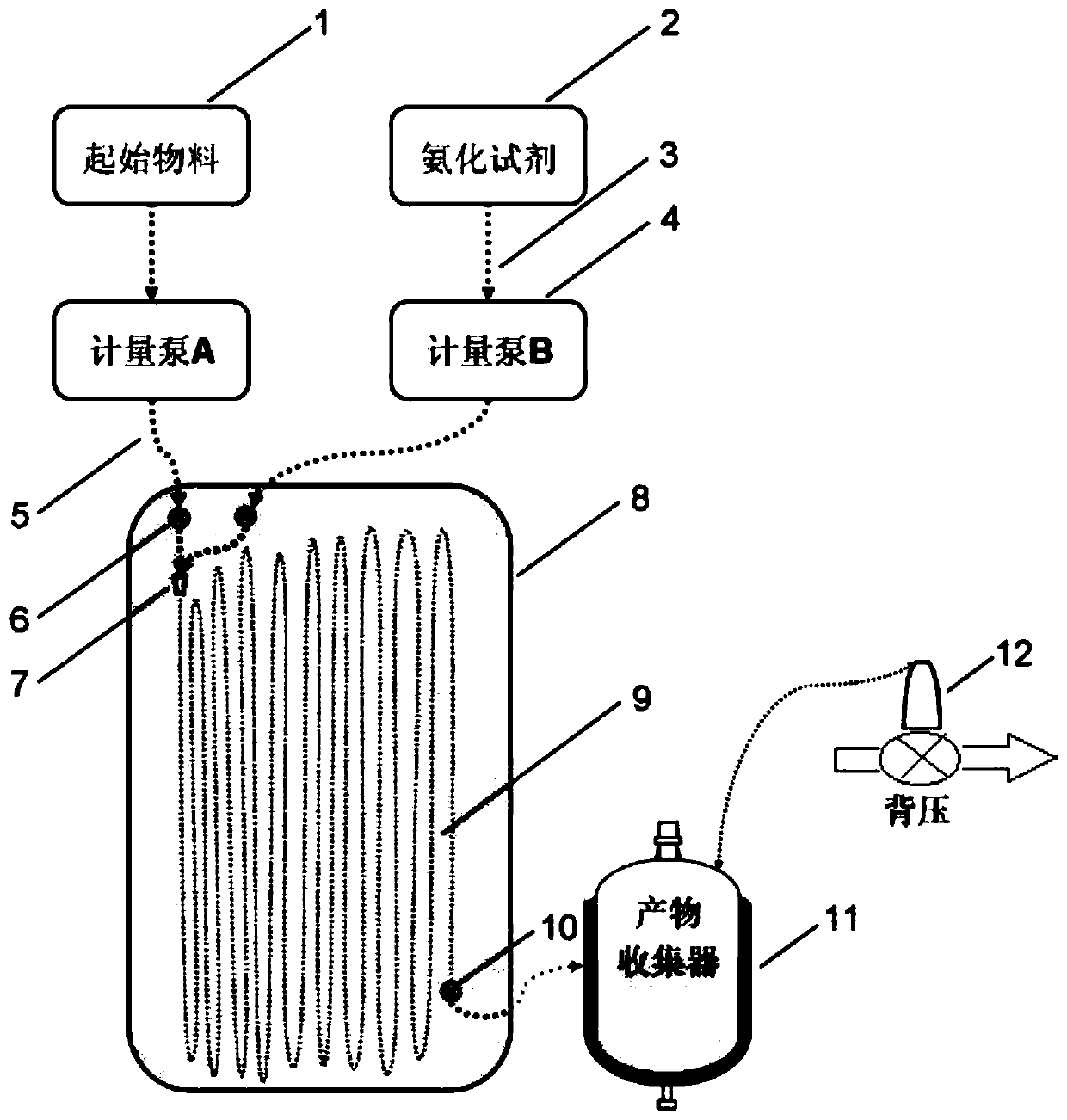

Method used

Image

Examples

Embodiment 1

[0045]Weigh m-trichlorotrinitrobenzene (31.65g, 0.10mol) and toluene (316.5g, about 365.5ml) in a flask, stir and dissolve until the color is bright, without visible fine particles, as starting materials; weigh 25 % thick ammonia water (0.60mol, about 44.83ml) is in the flask, as ammoniation reagent; Start metering pump feeding, starting material and ammoniation reagent are pumped into tunnel reactor, and the feeding rate of two pumps is set respectively 2.4ml / min and 0.3ml / min, so that the molar ratio of m-trichlorotrinitrobenzene to ammonia water is approximately 1:6, and the pump pressure in operation is 0.01~0.95Mpa (the pump pressure threshold is set to 1.80Mpa); The residence time in the channel reactor is about 1min, and the oil bath temperature is 70°C; samples are taken at the outlet of the microchannel reactor, and it is confirmed by liquid chromatography that part of m-trichlorotrinitrobenzene is converted into the product m-triaminotrinitrobenzene Nitrobenzene, the...

Embodiment 2

[0047] Weigh m-trichlorotrinitrobenzene (31.65g, 0.10mol) and toluene (316.5g, about 365.5ml) in a flask, stir and dissolve until the color is bright, without visible fine particles, as starting materials; weigh 25 % strong ammoniacal liquor (0.90mol, about 67.25ml) is in flask, as ammoniation reagent; Start metering pump feeding, starting material and ammoniation reagent are pumped into channel reactor, and the feed rate of two pumps is respectively set to 1.6ml / min and 0.3ml / min, so that the molar ratio of m-trichlorotrinitrobenzene and ammonia water is close to 1:9, the pump pressure during operation is 0.01~0.95Mpa (the pump pressure threshold is set to 1.80Mpa); the material in the channel The residence time in the channel reactor is about 3min, and the temperature of the oil bath is 90°C; the reaction material flows out from the channel reactor to the collector, and continues to keep warm for 0 to 5 hours; the sample is taken at the outlet of the channel reactor and analy...

Embodiment 3

[0049] Weigh m-trichlorotrinitrobenzene (31.65g, 0.10mol) and toluene (316.5g, about 365.5ml) in a flask, stir and dissolve until the color is bright, without visible fine particles, as starting materials; weigh 25 % strong ammoniacal liquor (0.90mol, about 67.25ml) is in flask, as ammoniation reagent; Start metering pump feeding, starting material and ammoniation reagent are pumped into channel reactor, and the feed rate of two pumps is respectively set to 4.8ml / min and 0.8ml / min, so that the molar ratio of m-trichlorotrinitrobenzene and ammonia water is close to 1:8, the pump pressure during operation is 1.3-1.5Mpa (the pump pressure threshold is set to 1.80Mpa, adjust the back pressure valve to maintain the pressure of the material in the reverse channel); the residence time of the material in the channel reactor is about 10min, the oil bath temperature is 110 ° C, and ultrasonic assistance is used; samples are taken at the outlet of the channel reactor and confirmed by liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com