Eutectic explosive containing trinitrobenzene and 1-nitronaphthalene and preparing method of eutectic explosive

A technology of trinitrobenzene and eutectic explosives, which is applied to explosives processing equipment, explosives, offensive equipment and other directions, can solve the problems of uneven density, poor mechanical properties, high toxicity, etc., and achieves simple operation and is suitable for large-scale industry. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

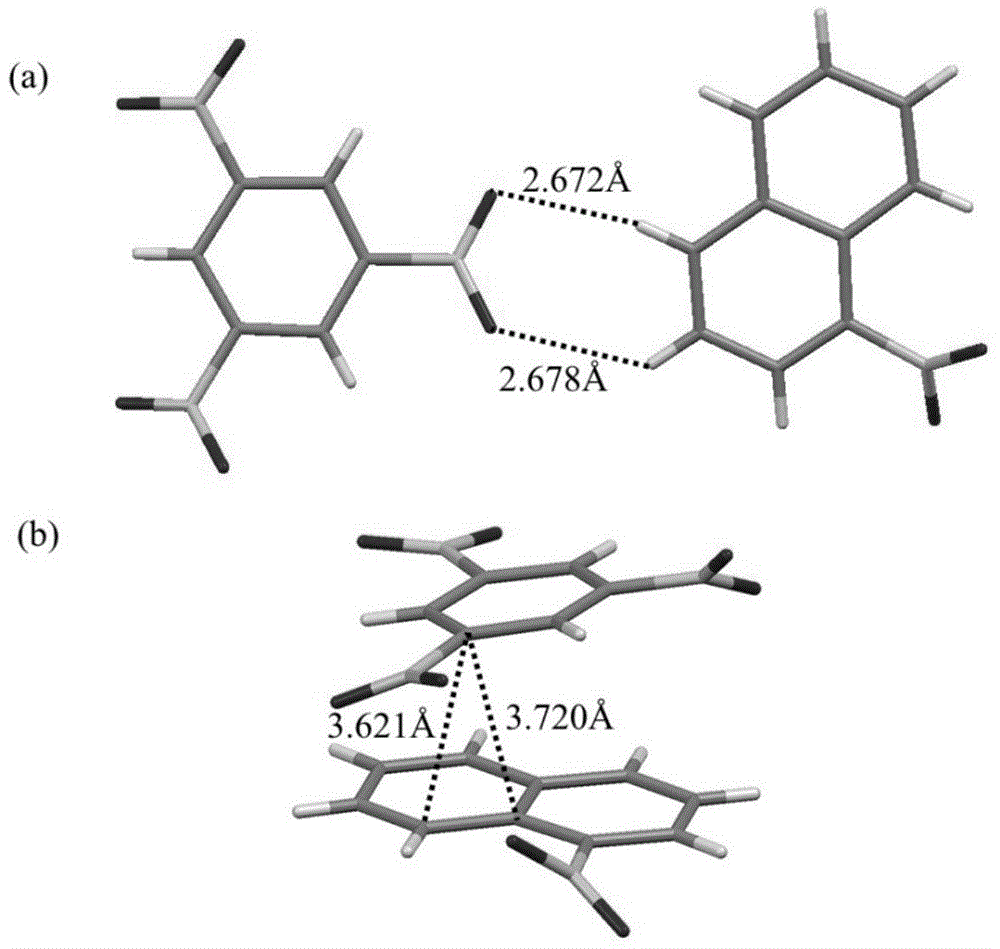

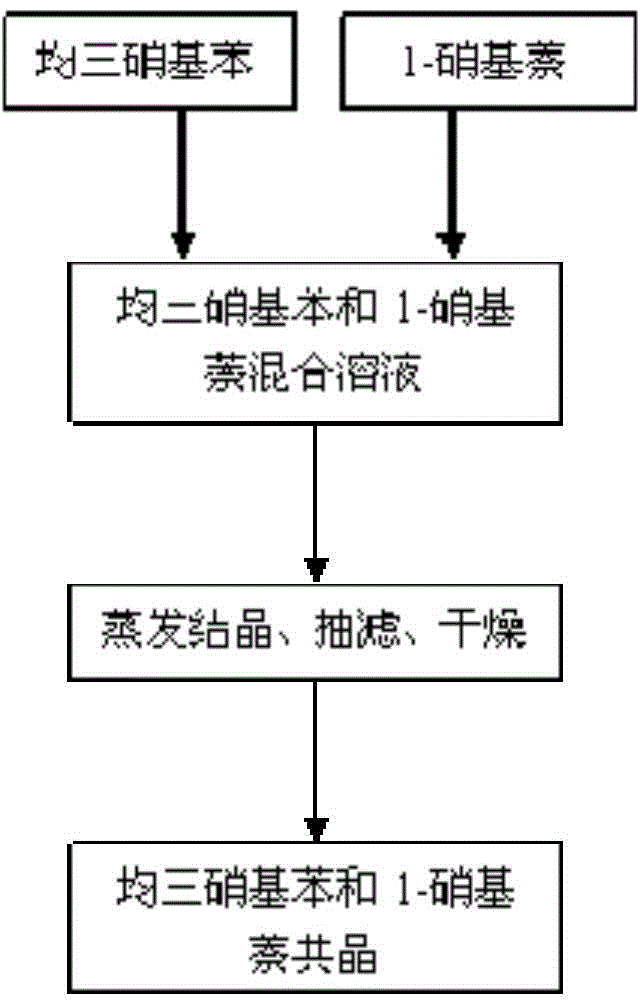

[0021] Dissolve 0.213g of s-trinitrobenzene and 0.346g of 1-nitronaphthalene in 50ml of acetonitrile, stir well, and filter to obtain a mixed solution of s-trinitrobenzene and 1-nitronaphthalene. The mixed solution was placed in a constant temperature and humidity chamber, and the temperature was set at 25°C. A few days later, the prismatic light yellow crystals were obtained, filtered by suction, and dried to obtain co-crystals of 3-trinitrobenzene and 1-nitronaphthalene. figure 1 A schematic diagram of the intermolecular forces in the cocrystal of s-trinitrobenzene and 1-nitronaphthalene.

Embodiment 2

[0023] Dissolve 0.426 g of s-trinitrobenzene and 0.173 g of 1-nitronaphthalene in 50 ml of methanol, stir well, and filter to obtain a mixed solution of s-trinitrobenzene and 1-nitronaphthalene. The mixed solution was placed in a constant temperature and humidity chamber, and the temperature was set at 40°C. A few days later, prismatic light yellow crystals were obtained, which were filtered and dried to obtain co-crystals of 3-trinitrobenzene and 1-nitronaphthalene.

Embodiment 3

[0025] Dissolve 0.213g of s-trinitrobenzene and 0.173g of 1-nitronaphthalene in 25ml of ethanol, stir well, and filter to obtain a mixed solution of s-trinitrobenzene and 1-nitronaphthalene. The mixed solution was placed in a constant temperature and humidity chamber, and the temperature was set at 40°C. A few days later, prismatic light yellow crystals were obtained, which were filtered and dried to obtain co-crystals of 3-trinitrobenzene and 1-nitronaphthalene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com