Preparation method of hyperbranched polysiloxane with controllable amino content

A technology of polysiloxane and content, applied in the field of synthesis of hyperbranched polymers, can solve the problems of high cost and limited scope, and achieve the effect of expanding the scope and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

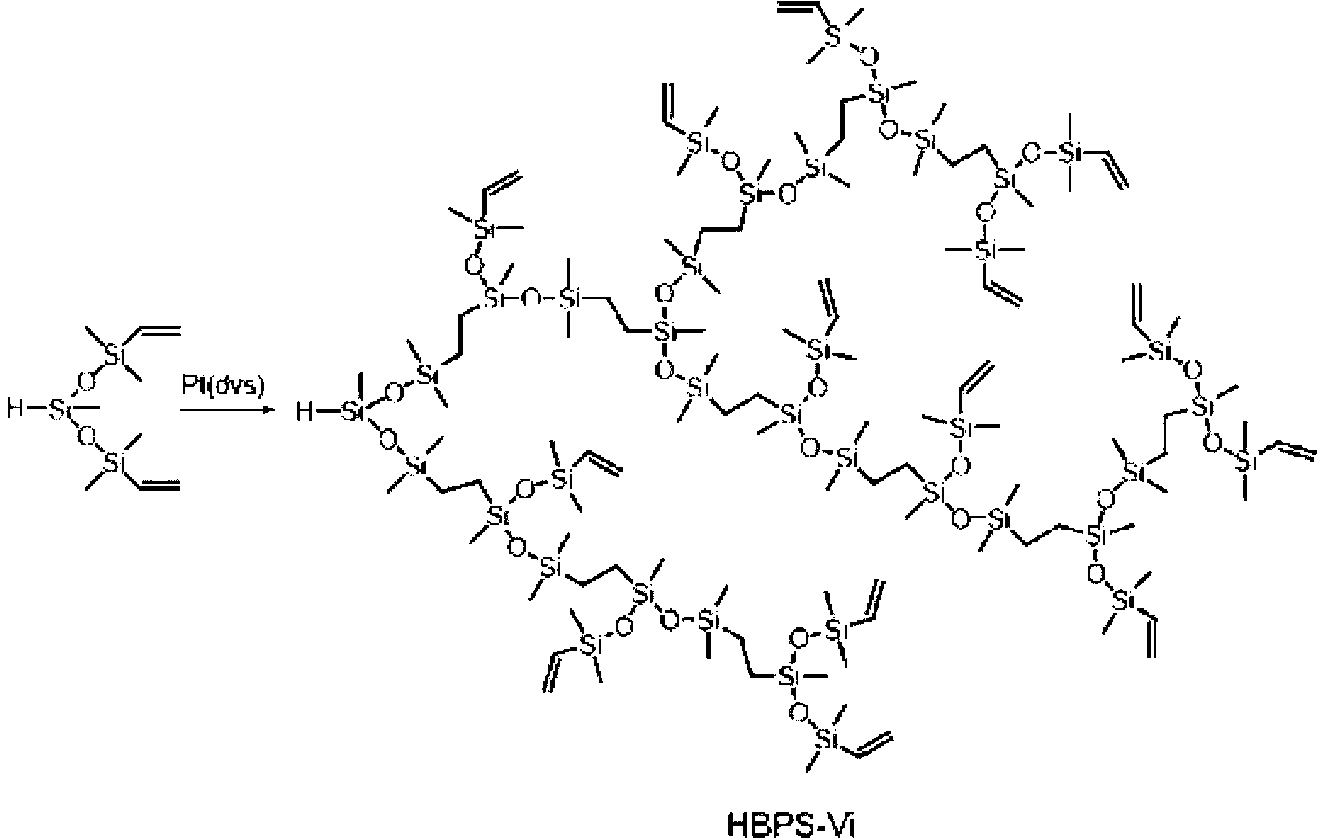

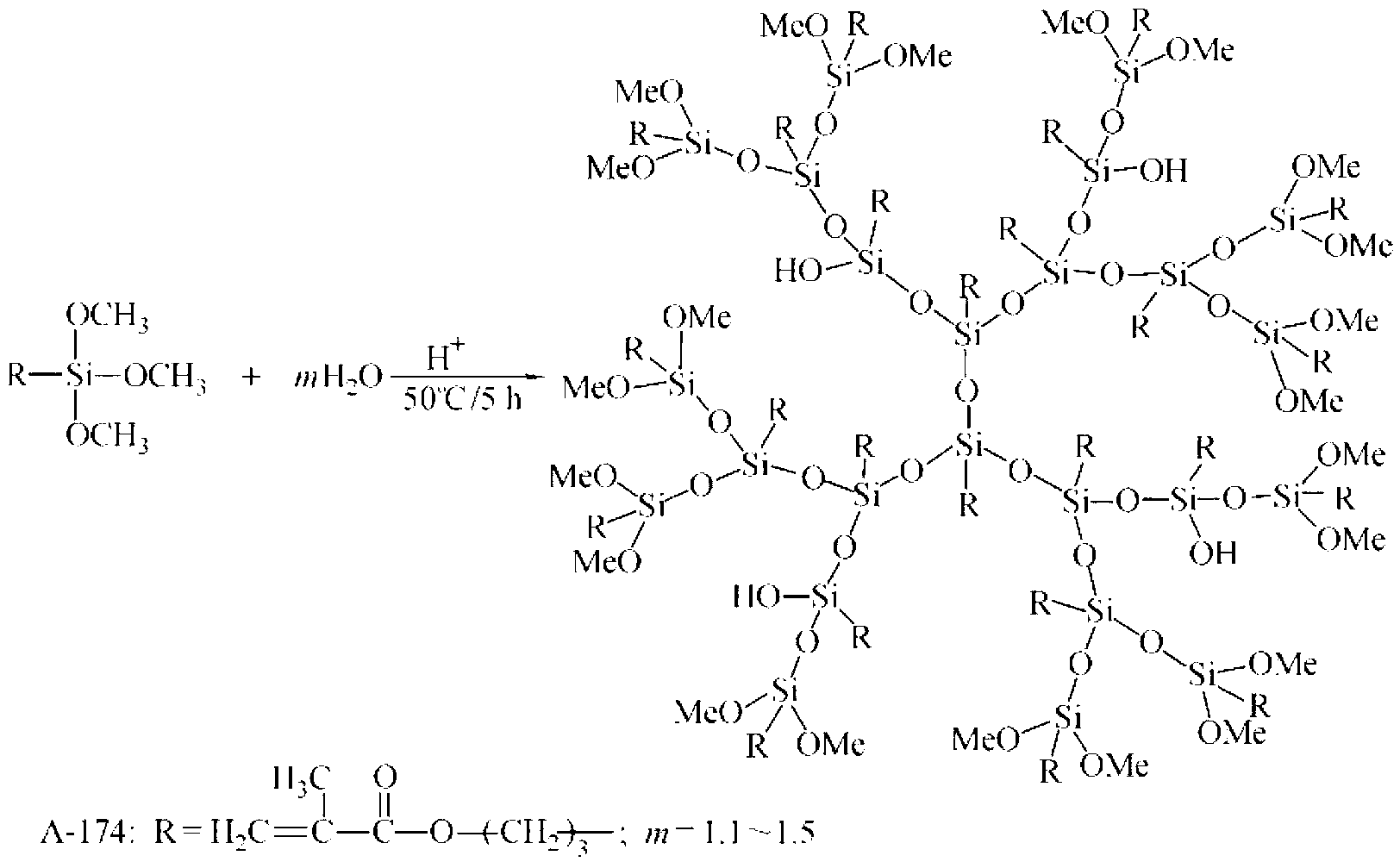

Method used

Image

Examples

Embodiment 1

[0025] (1) Add 16.15g DMAc, 15.2220g (0.1mol) TMOS, 7.2132g (0.06mol) dimethyldimethoxysilane, 1.7937g (0.01mol) 3-amino to the container equipped with an electric stirrer in sequence propyltrimethoxysilane, start stirring at the same time, and maintain the temperature of the system at -5~5℃;

[0026] (2) Calculate the molar ratio, slowly add 3.67g of distilled water to the system (1), stir and react at a constant temperature of -5~5°C for 1~2h, then raise the temperature to 60°C and continue stirring Reaction for 2h to obtain solution A;

[0027] (3) The solution A was evacuated for 2 to 3 hours at a temperature of 65-70 °C and a pressure of -0.075 MPa to remove the alcohol generated by the reaction to obtain a hyperbranched polysiloxane with an amino group content of 0.49 mmol / g.

Embodiment 2

[0029] (1) 20.17g DMAc, 20.8330g (0.1mol) TEOS, 7.2132g (0.06mol) dimethyldimethoxysilane, 2.2137g (0.01mol) KH550 were sequentially added to the container equipped with an electric stirrer, and simultaneously Start stirring and maintain the system temperature at -5~5℃;

[0030] (2) Calculate the molar ratio, slowly add 3.67g of distilled water to the system (1), stir and react at a constant temperature of -5~5°C for 1~2h, then raise the temperature to 60°C and continue stirring Reaction for 2h to obtain solution A;

[0031] (3) The solution A was evacuated for 2 to 3 hours at a temperature of 65 to 70 °C and a pressure of -0.075 MPa to remove the alcohol generated by the reaction to obtain a hyperbranched polysiloxane with an amino group content of 0.59 mmol / g.

Embodiment 3

[0033] (1) 18.39g DMAc, 20.8330g (0.1mol) TEOS, 8.8932g (0.06mol) dimethyldiethoxysilane, 4.4274g (0.02mol) KH550 were sequentially added to a container equipped with an electric stirrer, and simultaneously Start stirring and maintain the system temperature at -5~5℃;

[0034] (2) Calculate the molar ratio, slowly add 3.56g of distilled water to the system (1), stir and react at a constant temperature of -5~5°C for 1~2h, then raise the temperature to 60°C and continue stirring Reaction for 2h to obtain solution A;

[0035] (3) The solution A was evacuated for 2 to 3 hours at a temperature of 65 to 70 °C and a pressure of -0.075 MPa to remove the alcohol generated by the reaction to obtain a hyperbranched polysiloxane with an amino group content of 1.11 mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com