Intelligent optimal control method for car-bottom type furnace

An intelligent optimization and control method technology, applied in the control field, can solve problems such as low product quality and inability to accurately control trolley furnace production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The intelligent optimal control method of the bogie furnace of the present invention will be further elaborated below in combination with the embodiments.

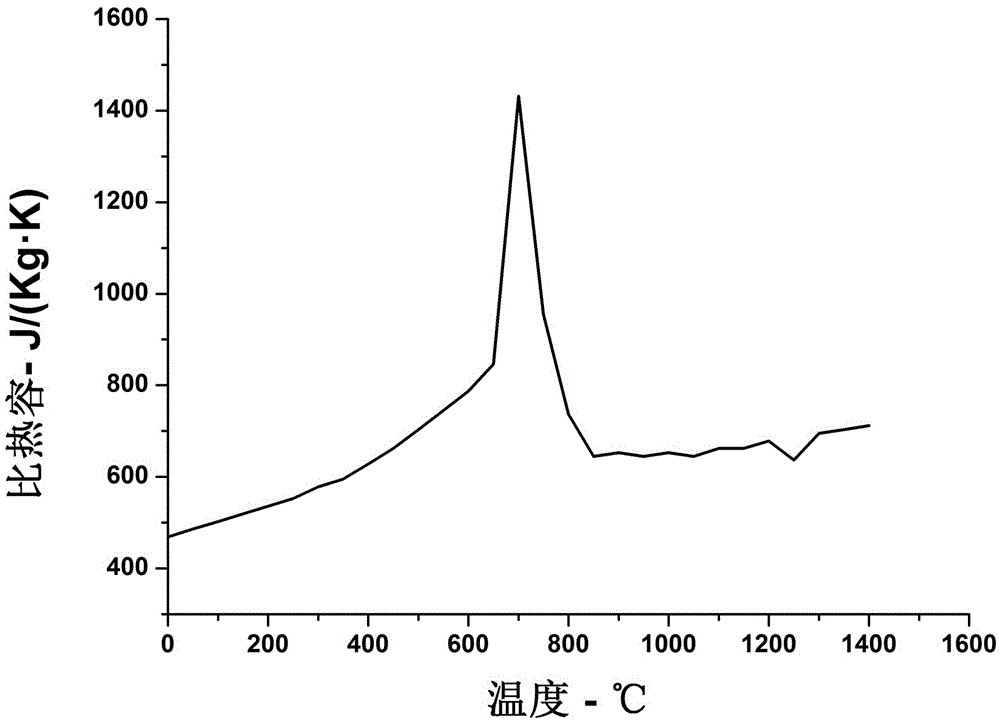

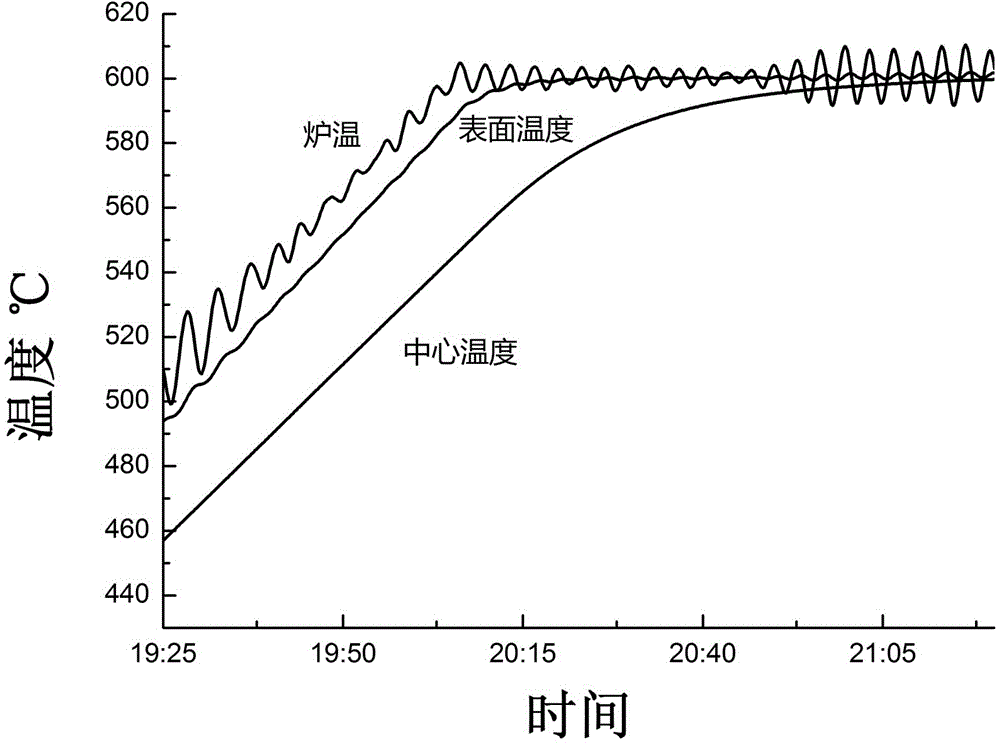

[0044] From PDI (basic data information) data, the size of the steel plate to be processed is 5500mm×1800mm×245mm, the steel type is Q345B, and the process parameters are heating for 4 hours to 600°C, then holding for 2.5 hours, and then heating for 3.5 hours to 900°C. Then keep warm for 6 hours. At the same time, obtain the thermal physical parameters required in the calculation process of the steel plate. For details, see figure 1 .

[0045] 1. Collect the furnace temperature in the trolley furnace: collect the furnace temperature in each section of the furnace from the basic automation system.

[0046] Generally speaking, the trolley furnace is relatively long, and the collection of furnace temperature only collects the furnace temperature of each section where the incoming material is located.

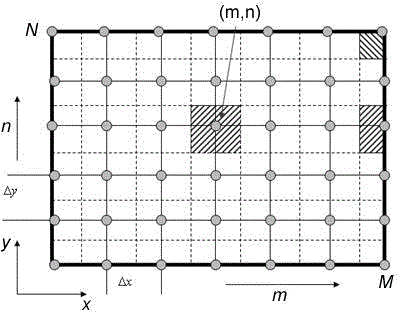

[0047] 2. Cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com