Condensation type clothes dryer and clothes drying method

A condensing, clothes dryer technology, applied in household clothes dryers, washing devices, textiles and papermaking, etc., can solve the problems of low energy utilization, wrinkled clothes, and easily damaged clothes, etc., to achieve high energy utilization, prevent Heat leakage, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A condensing clothes dryer and clothes drying method of the present invention will be described in detail below with reference to the drawings and embodiments.

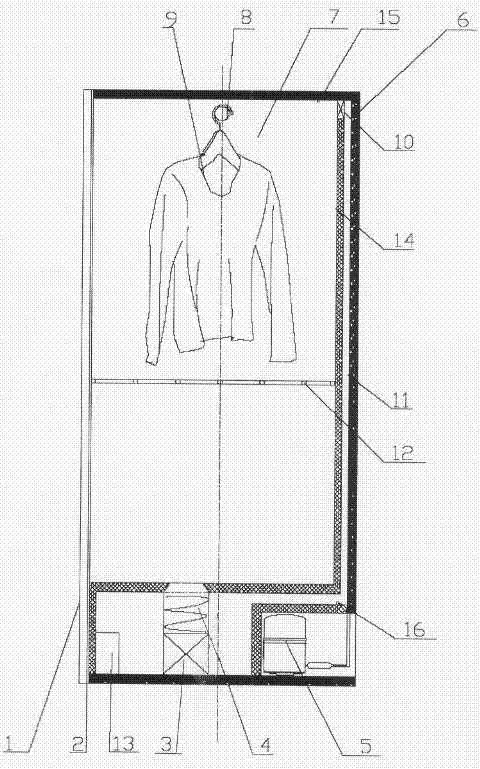

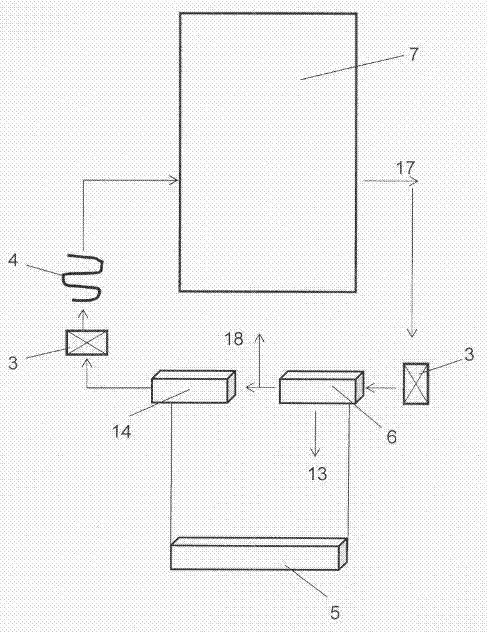

[0032] see figure 1 and figure 2 , the present invention provides a condensation type clothes dryer, which mainly consists of a box body 7, a compressor 5, an evaporator 6, a condenser 14, a hot air blower 3, a heating device 4, a humid heat air blower 10, a low temperature condensation wall 11, a water tank 13 and other components.

[0033] Casing 7 is made of outer casing, inner casing and insulation layer, and door body 1 is arranged on casing 7, and door seal 2 is housed on door body 1, and casing is sealed, prevents hot air from leaking out. The door seal 2 installed on the door body 1 can be a magnetic door seal.

[0034] The compressor 5 is installed at the bottom of the casing 7 . Evaporator 6 is installed on the back insulation layer of casing 7. Condenser 14 is installed in the foam layer on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com