Device and method for making aramid fiber mica paper

An aramid fiber and manufacturing device technology, which is applied to the aramid fiber mica paper manufacturing device and its manufacturing field, can solve the problems of high resource consumption, unstable electrical properties of mica paper, low strength, etc., and achieves improved papermaking efficiency and improved utilization. Value, the effect of stable electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

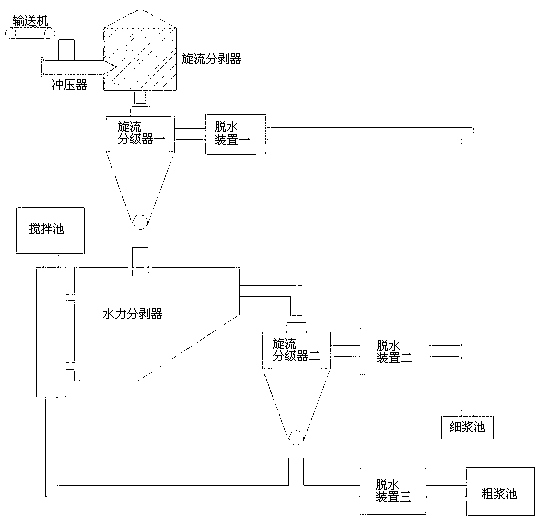

[0020] Such as figure 1 As shown, this embodiment provides an aramid fiber mica paper manufacturing device, including a swirl splitter and a stamper arranged next to the swirl splitter and communicated with it, and a raw material conveyor is arranged above the puncher The bottom of the cyclone splitter is also provided with a cyclone classifier 1, a dehydration device 1 and a hydraulic splitter connected with it respectively, and an aramid fiber stirring tank is also connected above the hydraulic splitter. Equipped with cyclone classifier two and dehydration device two.

[0021] The first and second dehydration devices are respectively provided with dewatering screens, and a fine slurry tank is provided under the dehydration screens.

[0022] A dehydration device three is also provided below the cyclone classifier two and the hydraulic stripper, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com