Bridge waterside foundation pit excavation and support method and support wall structure

A technology for supporting pile walls and water foundations, which is applied in infrastructure engineering, excavation, bridges, etc., can solve the problems of pile driving and pulling cost, high fence cost, high cost, inconvenient rigid support, etc., so as to reduce the construction cost. , the effect of increasing support strength and saving cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

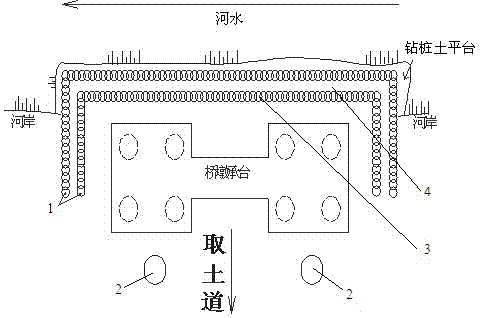

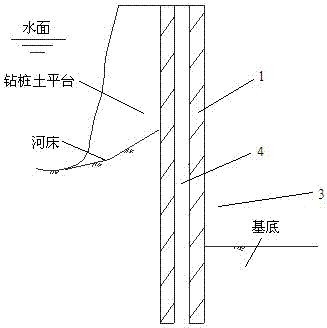

[0018] combine figure 1 and figure 2 As shown, in the present invention, the pile wall 3 is a horizontal "gate"-shaped structure, at least two rows are arranged, and a filling 4 is arranged between one row of pile walls 3 and another row of pile walls 3; two rows The distance between the pile walls 3 is in the range of 50 to 100 cm (in this implementation case, the distance between the two rows of pile walls 3 is 80 cm); the pile walls 3 are overlapped by a single cement mixing pile 1 Composition, pile wall 3 horizontal sections, both sides of its length direction are circular arc shape continuous; The angle of each circular arc of described circular arc continuous is in the range of 90~120 degrees (in this implementation case, the circular arc clip angle is 100 degrees).

[0019] With the above-mentioned excavation and support method for supporting the pile wall of the foundation pit of the bridge near the water, the method comprises the following steps: first, after the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com