Biaxial drawing test piece for testing strength of thermal barrier coating

A biaxial stretching, thermal barrier coating technology, applied in measuring devices, instruments, mechanical devices, etc., can solve the problem of inability to simulate the complex stress state of the coating system, and achieve the effect of uniform stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

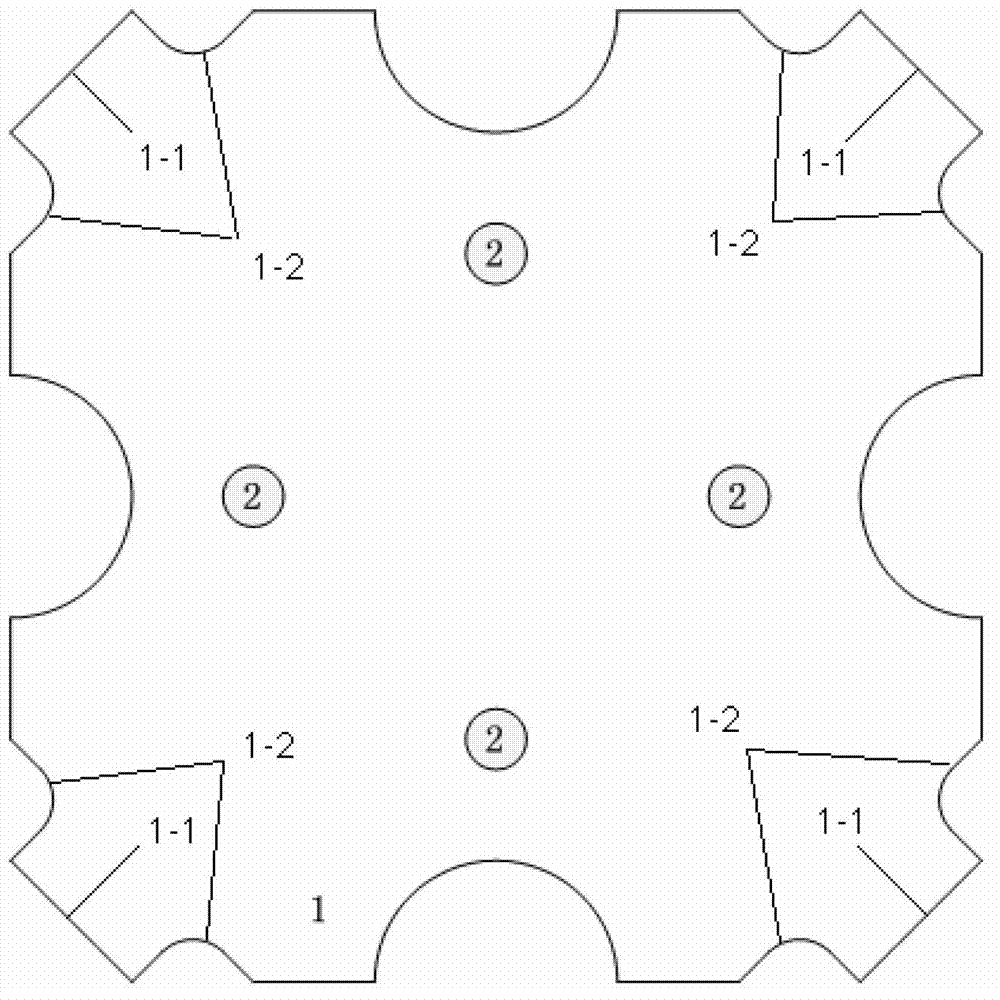

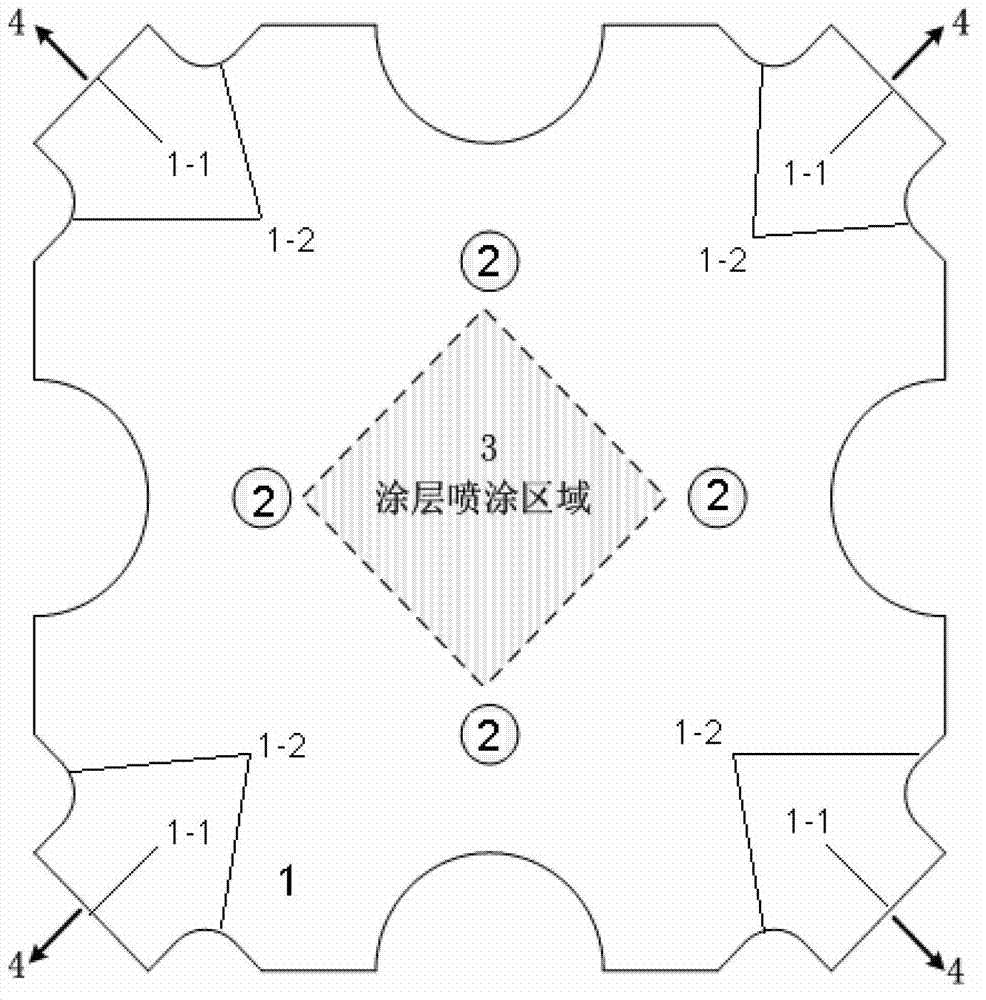

[0014] like figure 1 and figure 2 As shown, a biaxial tensile test piece of the present invention for testing the strength of a thermal barrier coating comprises a metal tensile base 1 and a base surface coating 3 sprayed on the surface of the metal tensile base 1, the metal tensile base 1 A sample designed to have biaxial tensile properties, the specific shape is: in two orthogonal directions, there are clamping handles 1-1 that can be clamped by the biaxial tensile machine, and the clamping handle 1-1 is compatible with the The main part of the part has a smooth transition area 1-2, the transition area 1-2 of the present embodiment is a circular arc, and four symmetrical circular holes 2 are opened in the middle of the metal tensile base 1; the base surface coating 3 takes the center position of the test piece as the axis of symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com