A detection method and detection device for the thermal performance of iron coke

A technology of thermal properties and detection methods, applied in the field of coking, can solve the problems of inability to truly simulate the behavior of coke, unscientific, slow temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

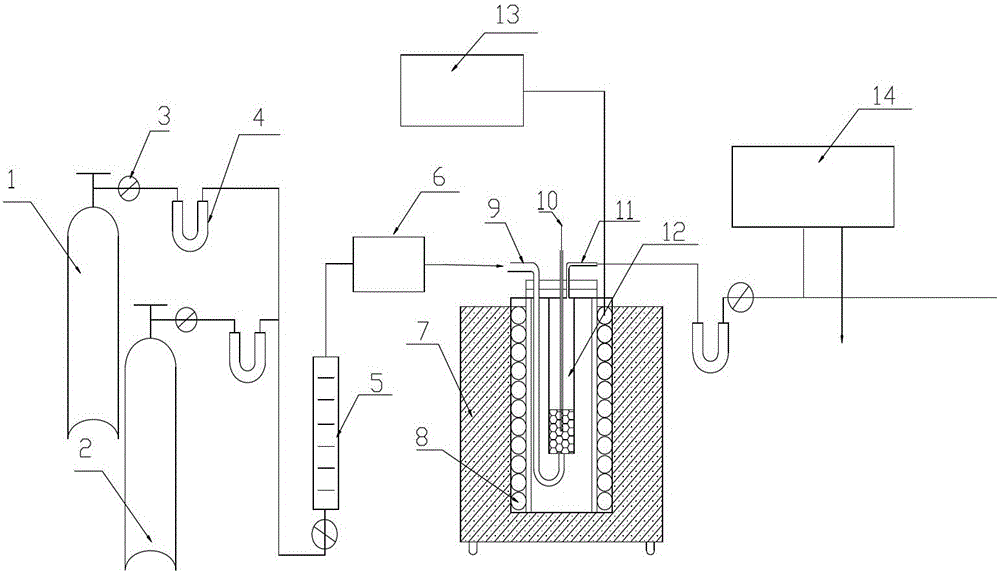

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] The detection device of the thermal performance detection method of iron coke includes an electric furnace 7, the silicon carbide rod 8 in the electric furnace 7 is connected with a precision temperature controller 13, a high-temperature alloy steel reactor 12 is inserted into the electric furnace 7, and the belt of the high-temperature alloy steel reactor 12 There are air inlet pipe 9, temperature control thermocouple 10 and air outlet pipe 11. Inside the reaction pipe of high temperature alloy steel reactor 12 are high alumina balls and iron coke samples from bottom to top, and temperature control thermocouple 10 is placed in the iron coke sample layer. Among them, the intake pipe 9 is connected with the flow regulator 6 and the flow meter 5 in turn, and the flow meter 5 is connected with the N 2 Cylinder 1 and CO 2 The gas cylinder 2 is connected, the gas outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com