Measuring method of solid-solution boron content in steel

A determination method and technology of boron content, applied in the field of analytical chemistry, can solve the problems of large error of subtraction method and uneven distribution of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The sample is made into a column with a diameter of 8mm and a length of 80mm, and a groove with a depth of 2mm is dug at a distance of 4mm from the top. Observation shows that there is no hole or crack.

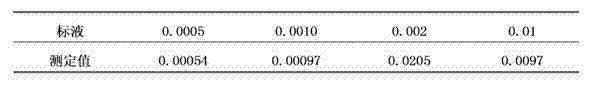

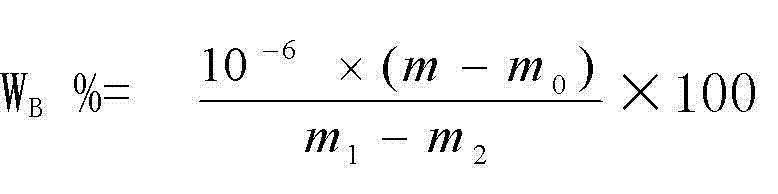

[0046] BT100H Steel 1 # Soak the sample in a measuring cup filled with 25mL of water and 25mL of ρ1.19g / mL hydrochloric acid for 30min, take it out, wash it, and dry it in the air; accurately weigh 88.4052g of the steel sample, use the weighed steel sample as the anode, and use the stainless steel cylinder As the cathode, put the glass beaker containing the prepared electrolyte into the electrolytic cell, electrolyze at 0.5A at 1°C for 90 minutes, remove it, put it into a 150mL quartz beaker for sampling by ultrasonic oscillation, and wash the steel sample with water. Rinse with ethanol, dry, and weigh 86.9012g. Take out the glass beaker from the electrolytic cell, stir the electrolyte solution after the electrolysis sample with a glass rod, pipette 10mL of the electr...

Embodiment 2

[0056] BT100H Steel 2 # The sample is made into a column with a diameter of 8mm and a length of 80mm, and a groove with a depth of 2mm is dug at a distance of 4mm from the top. Observation shows that there is no hole or crack, and it is quenched at 1150°C.

[0057] Soak the BT100H steel sample in a measuring cup filled with 25mL of water and 25mL of ρ1.19g / mL hydrochloric acid for 30min, take it out, wash it, and dry it in the air; accurately weigh 90.3174g of the steel sample, and use the weighed steel sample as the anode , the stainless steel cylinder is the cathode, put the glass beaker containing the prepared electrolyte into the electrolytic cell, the electrolysis current is 0.4A, and the electrolysis is performed at 3°C for 60 minutes, then it is removed, put into a 150mL quartz beaker for ultrasonic vibration sampling, and the steel sample is water Wash, rinse with ethanol, dry, and weigh 89.2947g. Take out the glass beaker from the electrolytic cell, stir the electr...

Embodiment 3

[0062] Will Q 960 Steel 1 # The sample is made into a column with a diameter of 6mm and a length of 80mm, and a groove with a depth of 2mm is dug at a distance of 4mm from the top. Observation shows that there is no hole or crack.

[0063] Soak the Q 960 steel sample in a measuring cup filled with 25mL of water and 25mL of ρ1.19g / mL hydrochloric acid for 35min, take it out, wash it, and dry it in the air; accurately weigh 77.7851g of the steel sample, and weigh the weighed steel sample as The anode, the stainless steel cylinder is the cathode, put the glass beaker containing the prepared electrolyte into the electrolytic cell, the electrolysis current is 0.5A, at 5°C, electrolyze for 75min, take it off, put it into a 150mL quartz beaker for ultrasonic vibration sampling, steel samples Wash with water, rinse with ethanol, dry, and weigh 76.5833g. Take out the glass beaker from the electrolytic cell, stir the electrolyte solution after the electrolysis sample with a glass rod, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com