Tunable metal grating polarizer with high extinction ratio

A metal grating and polarizer technology, applied in polarizing elements, optics, instruments, etc., to achieve the effect of easy realization, high extinction ratio, and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

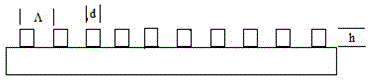

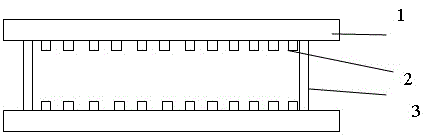

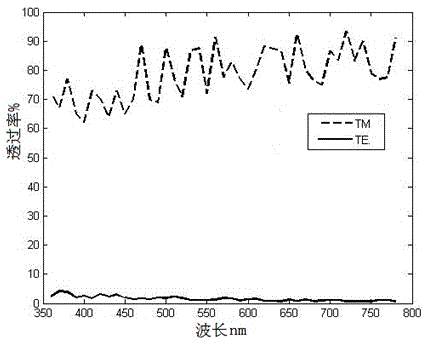

[0019] figure 1 It is a single-layer metal grating polarizer structure, and its structural parameters include metal grating period Λ, metal line width d and grating groove depth h. Assume that the metal material is aluminum, the groove shape of the grating is rectangular, the substrate is K9 glass, its thickness is 5mm, the period of the grating is 100nm, the metal line width is 50nm, and the groove depth of the grating is 50nm. According to the above parameters, the polarization characteristics of the structure can be calculated, such as image 3 Shown is the transmission T of the polarizer in the 360nm to 780nm band TM and transmittance T TE change curve, Figure 4 It is the variation curve of the extinction ratio Ex. It can be seen from the figure that with the increase of wavelength, T TM Both Ex and Ex have an increasing trend, but the intermediate fluctuations are also obvious. Among them, 740nm has the highest extinction ratio (about 150) and larger TM component tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com