Digital follow-up device for mechanized equipment and control method thereof

A follow-up device, digital control technology, applied in the direction of control using feedback, to achieve the effects of cost saving, simple structure and unique control algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

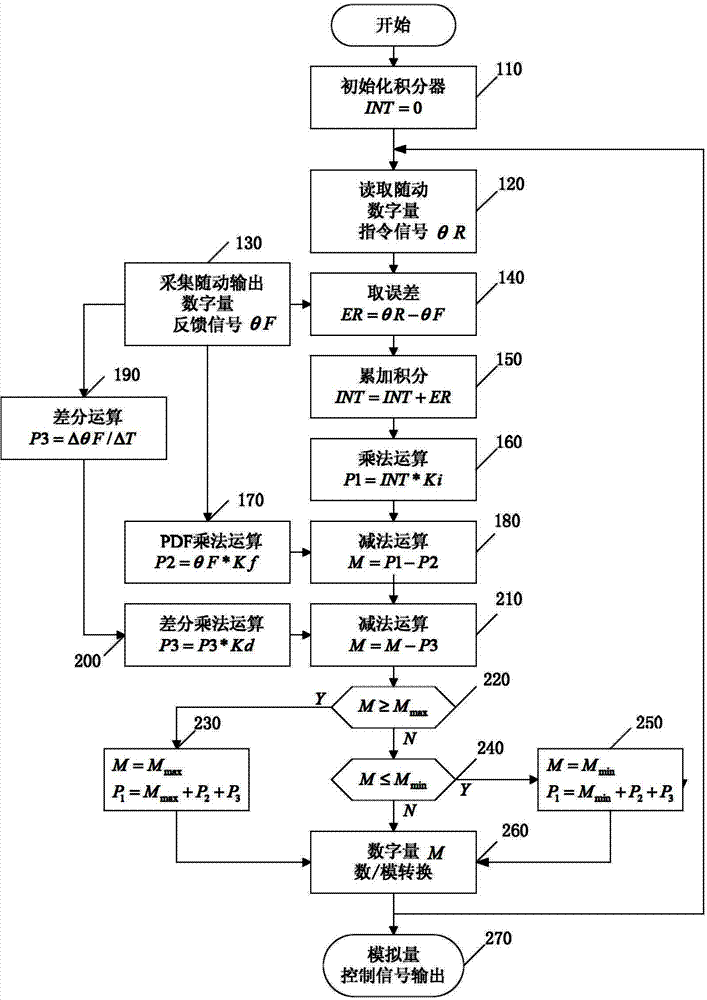

[0034] In order to deepen the understanding of the present invention, below in conjunction with appendix figure 1 And attached figure 2 Specific embodiments of the present invention are further described in detail.

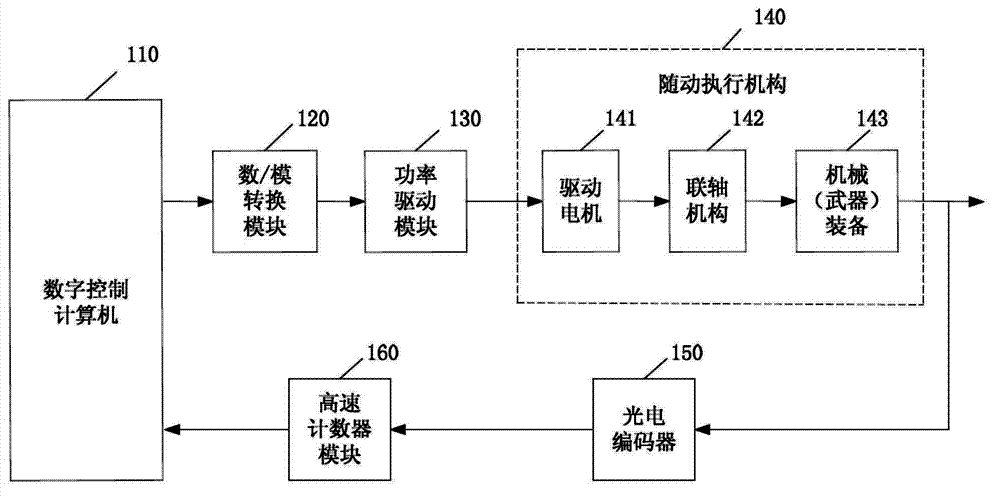

[0035] as attached figure 1 Shown is a block diagram of a digital follower for mechanical (weapon) equipment according to an embodiment of the present invention. This digital follow-up device is made up of digital control computer 110, digital / analog conversion module 120, power drive module 130, follow-up actuator 140, photoelectric encoder 150 and high-speed counting module 160, wherein said follow-up actuator 140 is driven by Motor 141, coupling 142 and mechanical (weapon) equipment 143; the digital control computer 110, digital / analog conversion module 120, power drive module 130, drive motor 141, coupling 142, mechanical (weapon) equipment 143 , the photoelectric encoder 150 and the high-speed counting module 160 are connected circularly in a clockwise di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com