Heat pump cycle

A heat pump cycle, heat technology, used in heat pumps, lighting and heating equipment, heating/cooling equipment, etc., to solve problems such as reduced vehicle fuel efficiency, heat transfer loss, and the inability of the engine to effectively defrost the evaporator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

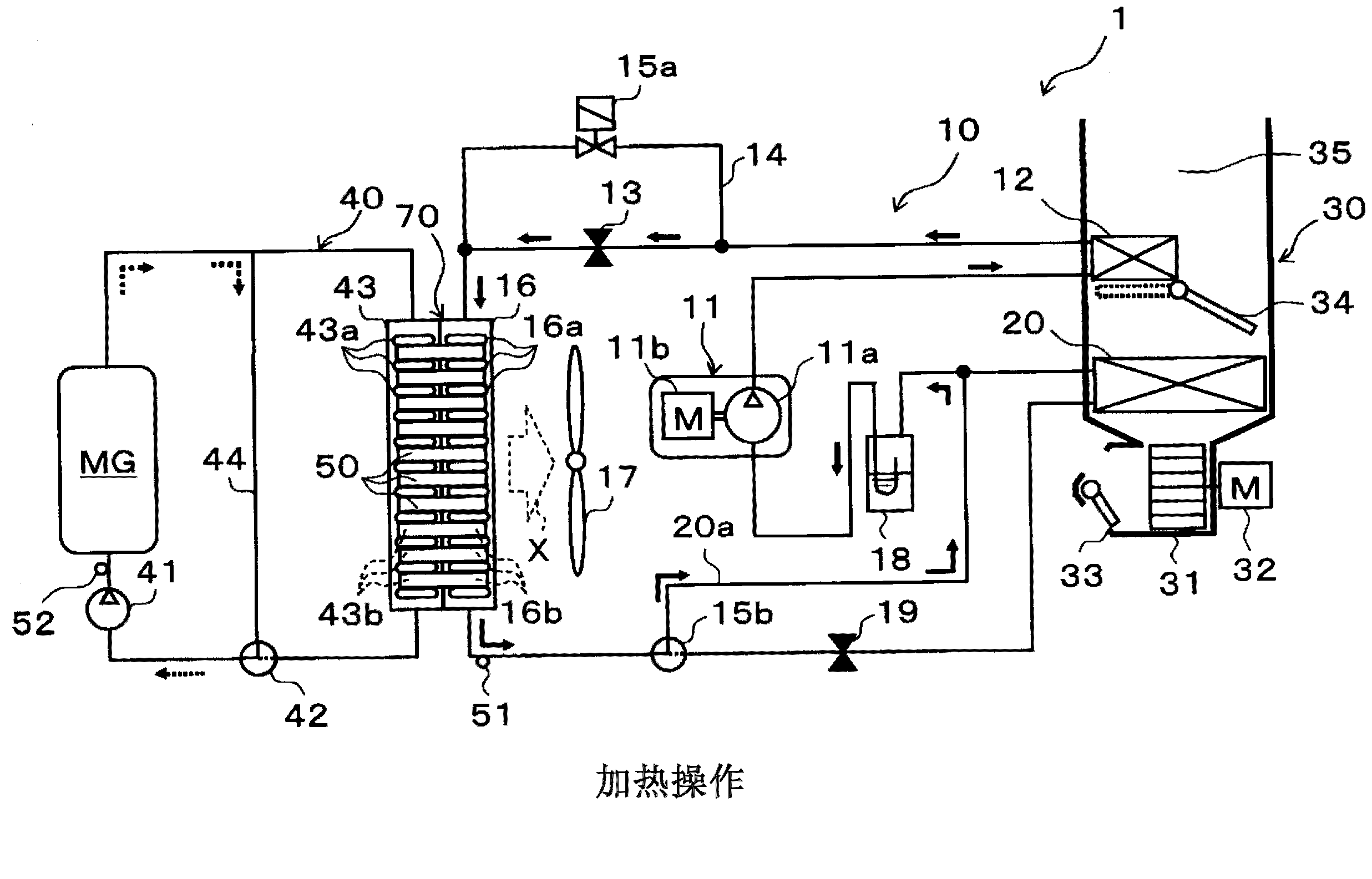

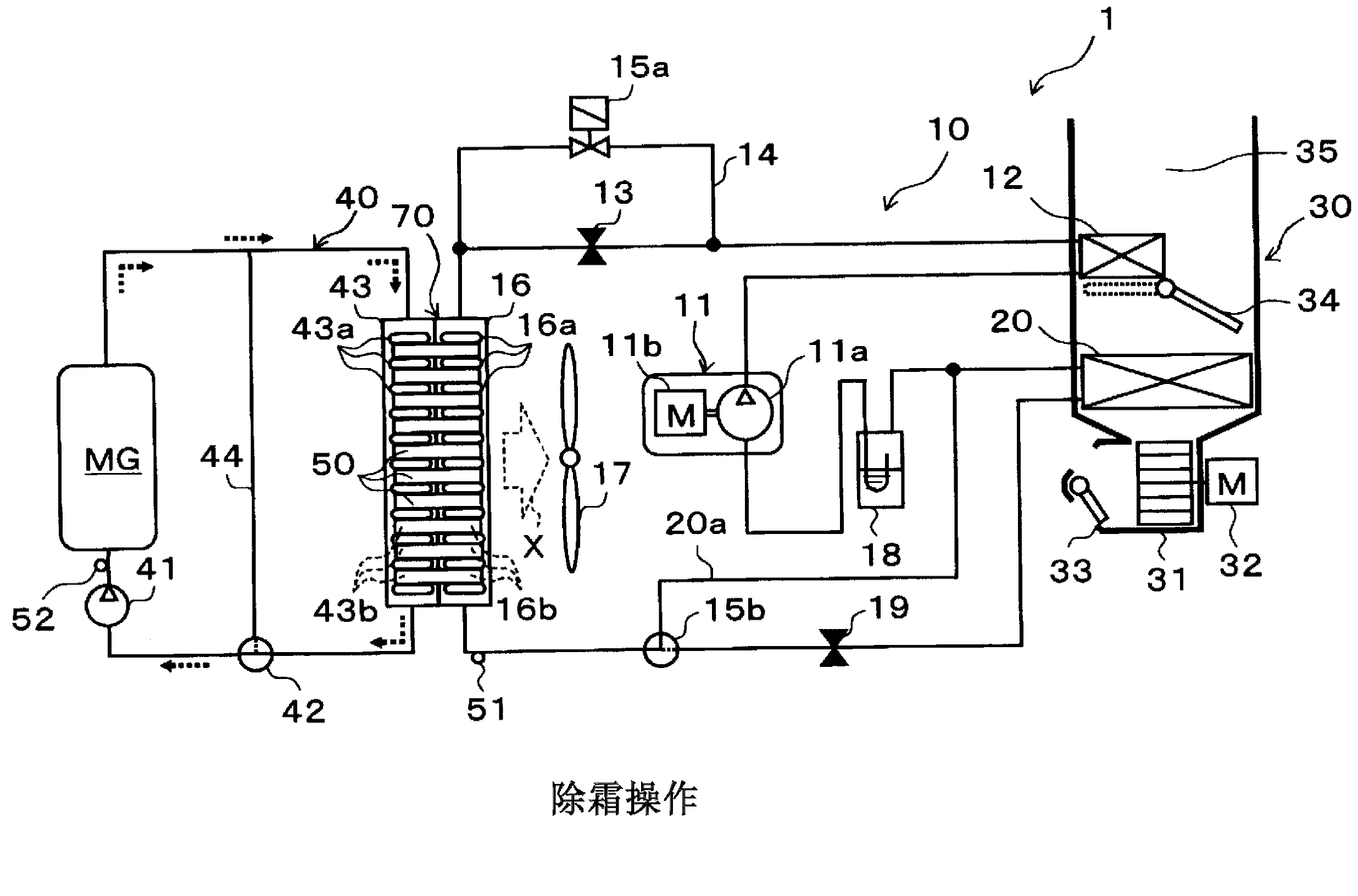

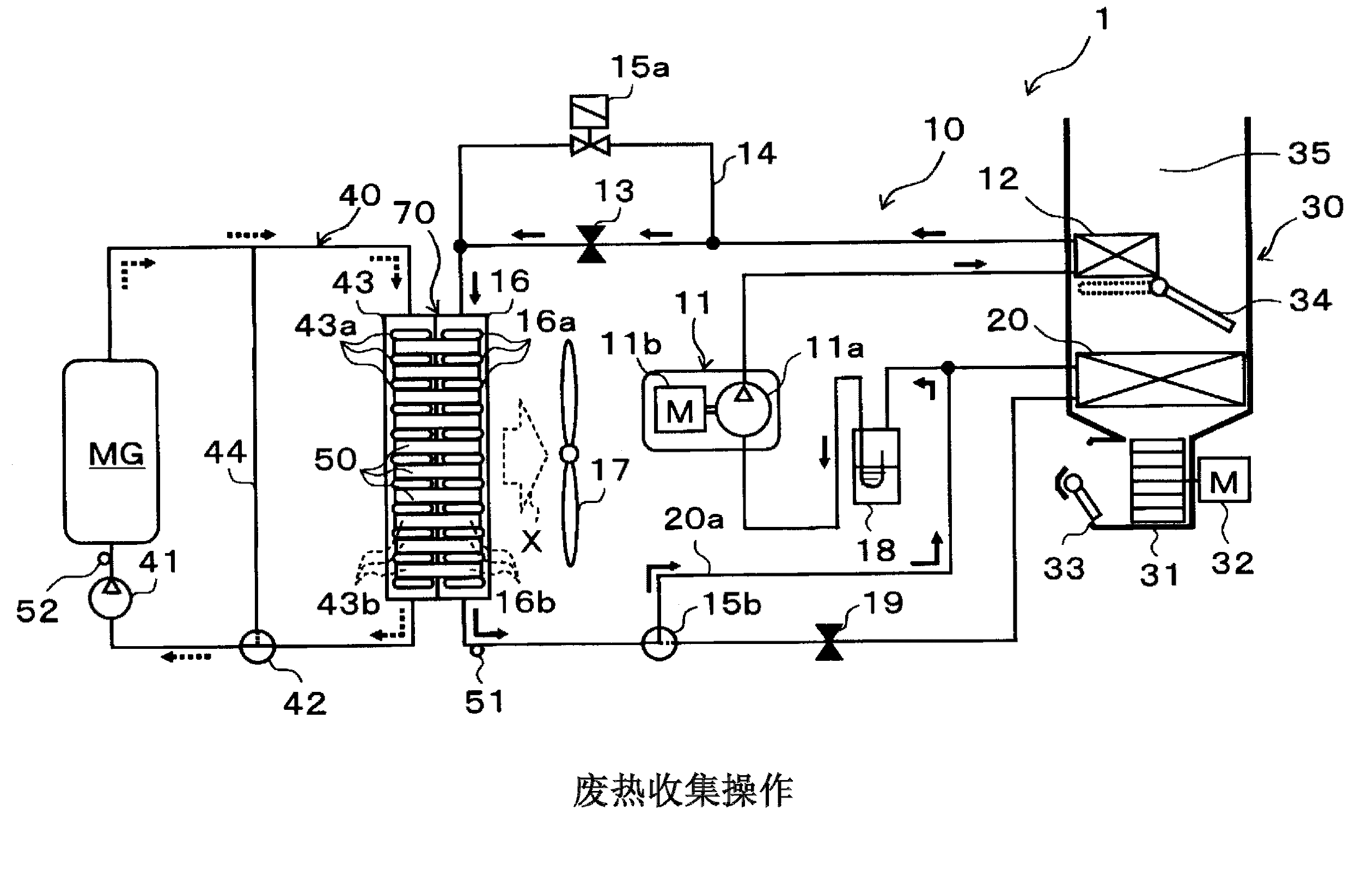

[0088] refer to Figure 1-5 , the first embodiment of the present invention will be described below. In this embodiment of the invention, the heat pump cycle 10 is applied to the air conditioner 1 of a vehicle called a hybrid vehicle that can obtain power from an internal combustion engine (engine) and an electric motor MG for travel. driving force. figure 1 An overall configuration diagram of the vehicle air conditioner 1 of the present embodiment is shown.

[0089] A hybrid vehicle can travel in a traveling state in which the vehicle obtains driving force from both the engine and the electric motor MG for traveling by running or stopping the engine according to the traveling load on the vehicle, etc. The electric motor MG obtains the driving force to switch between another traveling state of traveling. Therefore, a hybrid vehicle can improve fuel efficiency compared to a general car that only obtains driving force for traveling from an engine.

[0090] The heat pump cycl...

no. 2 example

[0214] Different from the first embodiment, in this embodiment, if Figure 6 As shown in the schematic diagram of the overall structure of , the indoor condenser 12 is removed, and the brine circuit 60 is provided for circulating brine, ie, as an example of a heating fluid. Figure 6 is a schematic diagram showing the overall structure of the refrigerant flow path etc. during the heating operation in this embodiment, where the flow of the refrigerant in the heat pump cycle 10 is indicated by a solid line, and the flow of the coolant in the coolant circulation circuit 40 is indicated by a broken line arrow express.

[0215] exist Figure 6 In , the same or equivalent parts as those of the first embodiment are denoted by the same reference numerals. The same applies to the other drawings below.

[0216] The brine in this embodiment is a heating fluid for transferring heat contained in the refrigerant discharged from the compressor 11 to the air blown into the vehicle interior...

no. 3 example

[0223] Different from the heat pump cycle 10 of the first embodiment, such as Figure 7 As shown in the schematic diagram of the overall structure, in this embodiment, the outdoor unit bypass channel 64 is added to allow the refrigerant flowing from the fixed throttling device 13 for heating or the bypass channel 14 for the fixed throttling device to bypass the outdoor unit. heat exchanger 16. In addition, an opening / closing valve 15c is further added to open and close the outdoor unit bypass passage 64 .

[0224] Figure 7 is a schematic diagram showing the overall structure of the refrigerant flow path during the defrosting operation in this embodiment, in which the flow of the refrigerant in the heat pump cycle 10 is indicated by a solid line, and the flow of the coolant in the coolant circulation circuit 40 is indicated by a dashed arrow express.

[0225] The opening / closing valve 15c has the same basic structure as that of the opening / closing valve 15a provided in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com