Preparation method for Shuanghuanglian granules

A technology of shuanghuanglian and granules, applied in the field of preparation of shuanghuanglian granules, can solve the problems of long production cycle, low production capacity, and many workers, and achieve the effect of reducing labor intensity and avoiding environmental damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

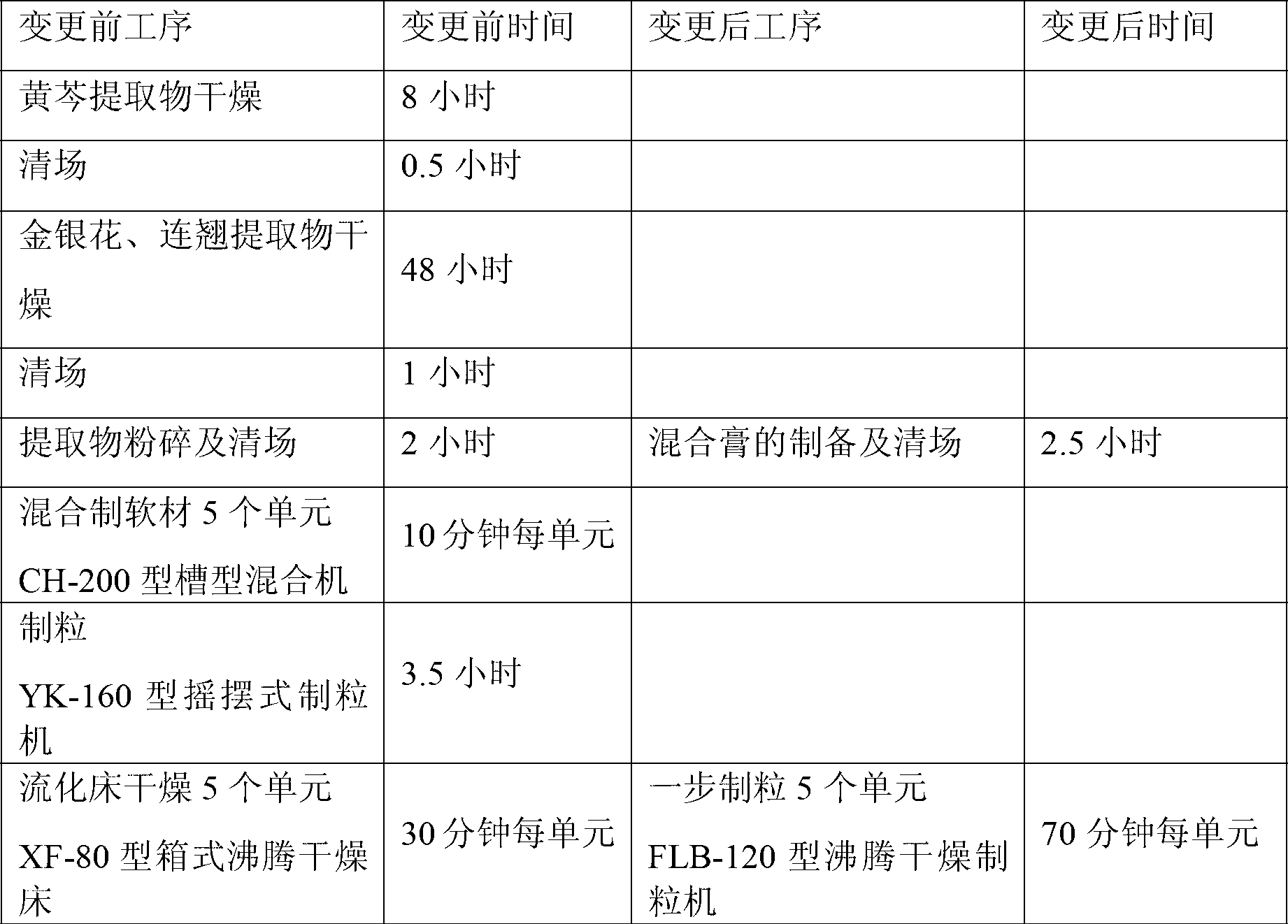

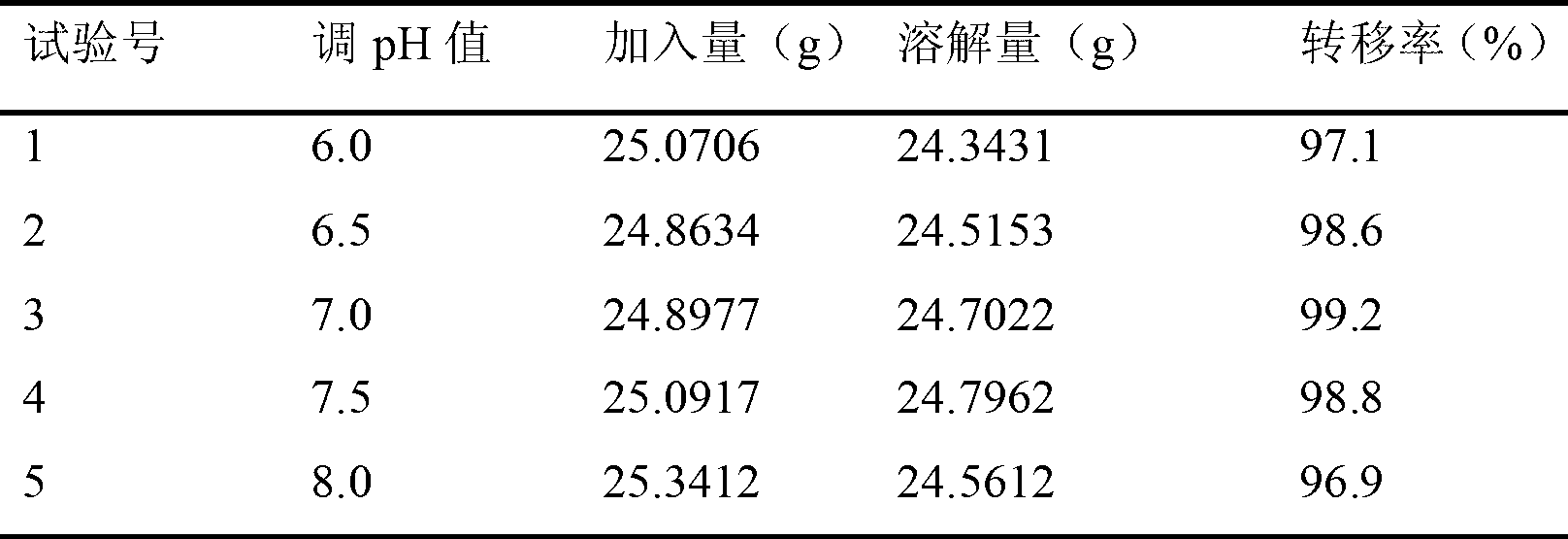

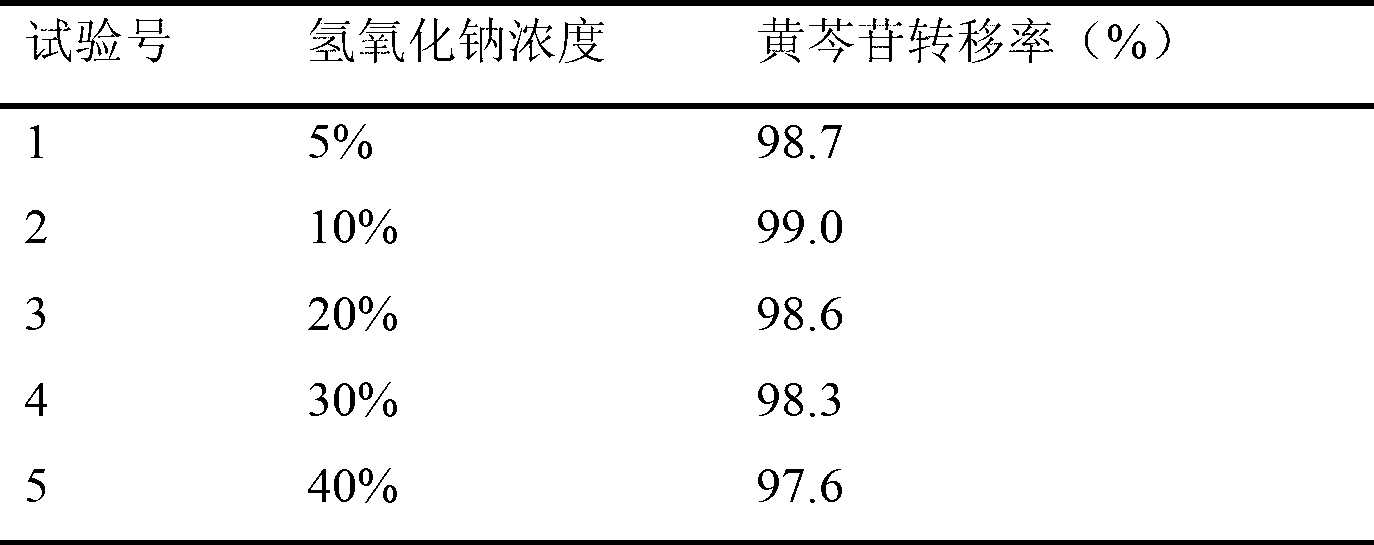

[0013] Specific embodiment one: the preparation method of a kind of Shuanghuanglian granules of the present embodiment is carried out according to the following steps: take the wet paste of Scutellaria baicalensis extract, add 2.5 to 4 times the weight of water and mix it evenly, and then adjust it with sodium hydroxide solution. When the pH value reaches 7.0, stir to dissolve, add honeysuckle and forsythia mixed extract paste according to the prescription amount, then concentrate to a clear paste with a relative density of 1.09~1.12, let cool to 50°C, filter, collect the filtrate as a binder, and add auxiliary materials , boiled, dried and granulated to obtain Shuanghuanglian granules.

[0014] The relative density of the clear paste in this embodiment is the density relative to water at a temperature of 75°C to 85°C.

[0015] The Scutellaria baicalensis extract wet ointment and the mixed extract ointment of honeysuckle and forsythia described in this embodiment are prepared ...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that: the pH range is 6.5-7.5. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the relative density is measured at a temperature of 75°C to 85°C. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com