Superfine grinding method for domestic soybean milk machine

An ultra-fine grinding, soymilk machine technology, applied in applications, home appliances, kitchen appliances, etc., can solve the problems affecting work efficiency and quality, the difficulty of cleaning the teeth of the dynamic grinding disc and the cutting teeth of the static grinding disc, and the difficulty of reaching sub-micron or even nano-scale, etc. problem, to achieve the effect of improving the utilization rate and avoiding the separation step of bean dregs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

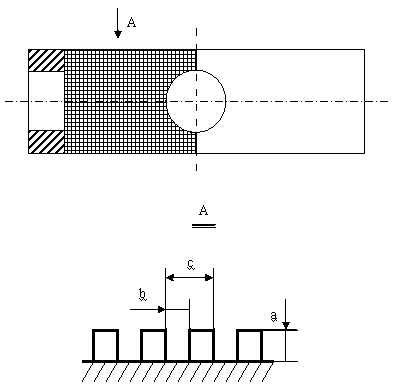

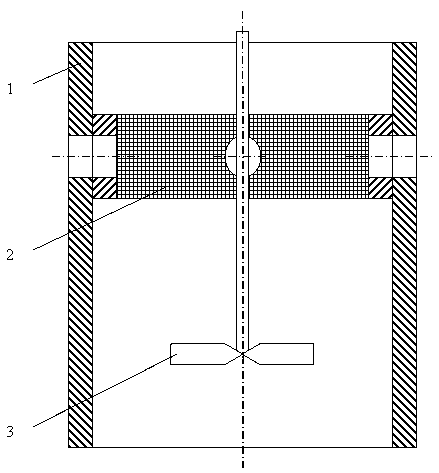

[0022] This embodiment specifically implements a method of ultrafine grinding for household soybean milk makers. First, a group of 4 round holes with a diameter of 8mm are opened on the spoiler connected to the existing soybean milk machine base. Evenly distributed on the circumference, a rack-shaped fixed knife made of ordinary carbon steel material is set in the direction of the above-mentioned holes facing the liquid flow, placed in the spoiler of the soybean milk machine and closely attached to the inner wall of the spoiler, the fixed knife Four round holes with a diameter of 8mm are also opened and correspond to the positions of the round holes on the spoiler; the surface of the fixed knife has grooves perpendicular to each other, with a width of 0.5mm and a depth of 0.5mm, and the distance between adjacent grooves is 1.0mm. Evenly distributed on the entire inner cylindrical surface; the fixed knife is 14mm wide and 2mm thick, symmetrical up and down in the round hole.

...

Embodiment 2

[0025] This embodiment specifically implements a kind of ultra-fine grinding method for household soybean milk machines proposed by the present invention. First, a group of 10 round holes with a diameter of 8 mm are opened on the spoiler connected to the base of the existing soybean milk machine. The group of circular holes is evenly distributed on the circumference, and a rack-shaped fixed knife made of ordinary carbon steel material is set in the direction of the above-mentioned holes facing the liquid flow, placed in the spoiler of the soybean milk machine and closely attached to the inner wall of the spoiler , 10 round holes with a diameter of 8mm are also set on the fixed knife and correspond to the positions of the round holes on the spoiler; the surface of the fixed knife has grooves perpendicular to each other, with a width of 1.0mm and a depth of 1.0mm, and the distance between adjacent grooves is 2.0mm, evenly distributed on the entire inner cylindrical surface; the f...

Embodiment 3

[0028] In this embodiment, a kind of ultra-fine pulverization method for household soybean milk machine proposed by the present invention is concretely implemented. First, a group of 8 round holes with a diameter of 10 mm are opened on the spoiler connected to the base of the existing soybean milk machine. The group of circular holes is evenly distributed on the circumference, and a rack-shaped fixed knife made of ordinary carbon steel material is set in the direction of the above-mentioned holes facing the liquid flow, placed in the spoiler of the soybean milk machine and closely attached to the inner wall of the spoiler , 8 round holes with a diameter of 10mm are also set on the fixed knife and correspond to the positions of the round holes on the spoiler; the surface of the fixed knife has grooves perpendicular to each other, with a width of 0.8mm and a depth of 0.8mm, and the distance between adjacent grooves is 1.6mm, evenly distributed on the entire inner cylindrical surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com