A method and device for preparing foamed aluminum from semi-solid slurry based on the blowing method

A technology of semi-solid slurry and foamed aluminum, which is applied in the field of porous foam materials, can solve the problems of affecting the thermal conductivity of foamed aluminum products, low recycling rate, affecting the properties and preparation efficiency of foamed aluminum products, and slowing down the inherent liquid separation phenomenon, saving materials and costs, and achieving the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

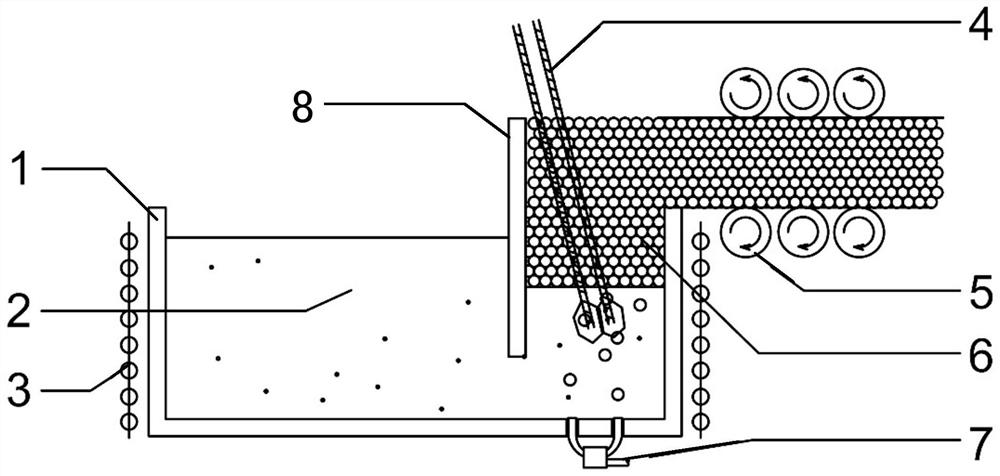

[0027] The structure of the device for preparing foamed aluminum from semi-solid slurry based on the blowing method is as follows: figure 1 As shown, including the crucible 1 and the internal partition 8, there is a gap between the bottom of the partition 8 and the inner bottom surface of the crucible 1, and the top edge of the partition 8 is higher than the upper edge of the crucible 1; the partition 8 separates the inside of the crucible into storage The liquid chamber and the foaming chamber, the foaming chamber is equipped with a stirring paddle 4; the bottom of the crucible 1 is provided with a vent hole opposite to the top 4 of the stirring paddle; the outside of the crucible 1 is provided with a bottom blowing nozzle 7 connected to the vent hole; the outside of the crucible 1 is surrounded There is an induction coil 3;

[0028] The crucible 1 is provided with a traction wheel 5 along the outer side and placed in parallel with the partition 8;

[0029] The traction whe...

Embodiment 2

[0038] Device structure is the same as embodiment 1;

[0039] Method is with embodiment 1, and difference is:

[0040] The obtained aluminum foam has an average pore diameter of 5mm and a porosity of 90%.

Embodiment 3

[0042] Device structure is the same as embodiment 1;

[0043] Method is with embodiment 1, and difference is:

[0044] The obtained aluminum foam has an average pore diameter of 10mm and a porosity of 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com