Method for preparing nano-silver water solution by modified glucose

A technology of glucose and nano-silver is applied in the field of preparation of nano-silver colloidal solution, which can solve the problems of uneven particle size, uneven distribution, and high preparation cost, and achieves low human irritation, high human safety, and good medical value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Dissolve 5g of 2-(3-carboxy-1-propionylamino)-2-deoxy-D-glucose in 100ml deionized water to obtain 5% 2-(3-carboxy-1-propionylamino)- 2-deoxy-D-glucose aqueous solution;

[0019] 2. Dissolve 1g of glucose in 100ml of deionized water to obtain a 1% glucose aqueous solution;

[0020] 3. Configure a silver nitrate solution with a mass fraction of 7.87g / L, add dropwise 10% ammonia solution until the precipitate disappears, and obtain a silver ammonia solution with a mass fraction of 7.87g / L;

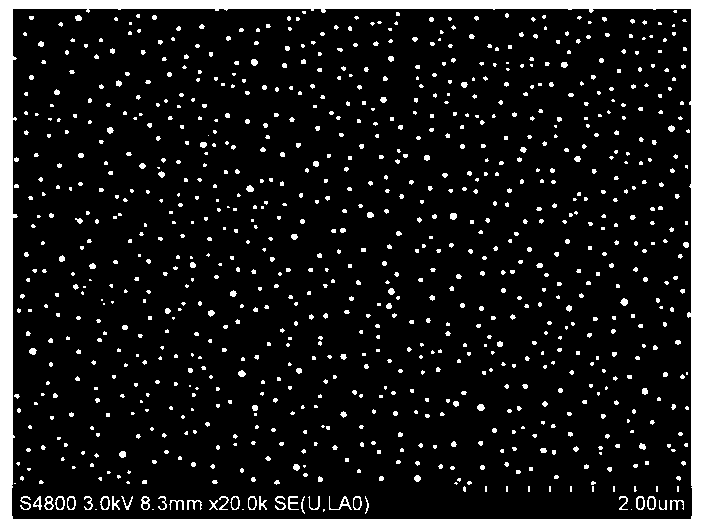

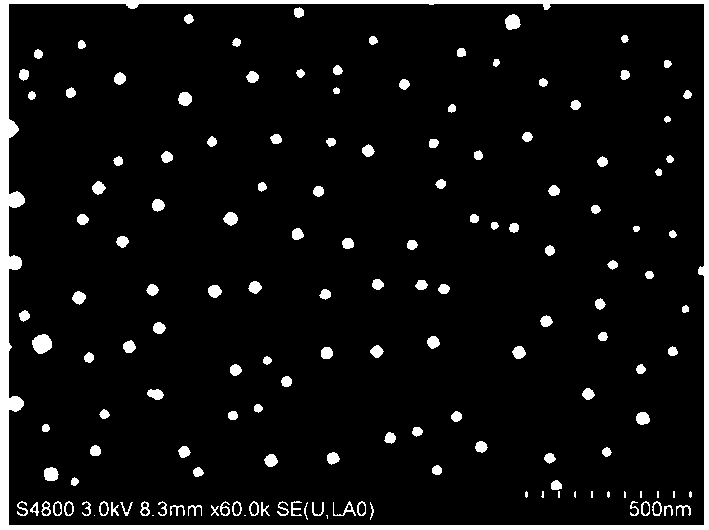

[0021] 4. Mix 5% 2-(3-carboxy-1-propionylamino)-2-deoxy-D-glucose aqueous solution, 1% glucose aqueous solution and silver ammonia solution with a mass fraction of 7.87g / L at a ratio of 10:1 : 2 volume ratio mixing, stirring at a temperature of 60° C. for 10 h to obtain a nano-silver solution with a particle size of 5-70 nm.

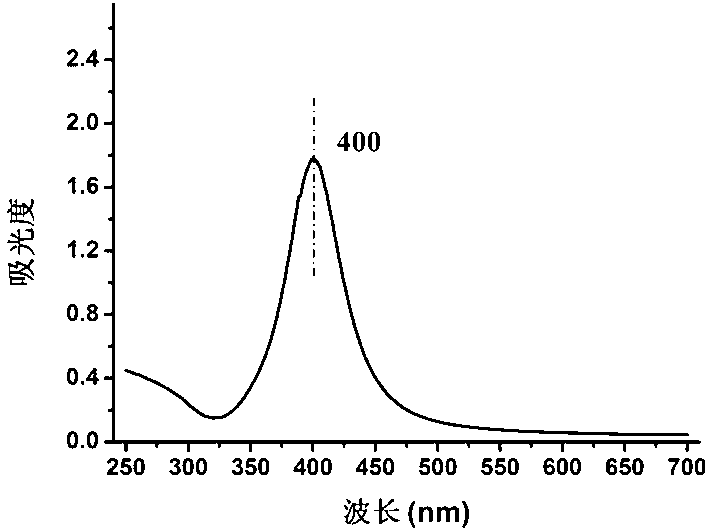

[0022] Referring to accompanying drawing 1, it is the ultraviolet spectrogram of the nano-silver colloidal solution that the present embodiment provides...

Embodiment 2

[0026] 1. Dissolve 5g of 2-(3-carboxy-1-propionylamino)-2-deoxy-D-glucose in 100ml deionized water to obtain 5% 2-(3-carboxy-1-propionylamino)- 2-deoxy-D-glucose aqueous solution;

[0027] 2. Dissolve 1g of fructose in 100ml of deionized water to obtain a 1% fructose aqueous solution;

[0028] 3. Configure a silver nitrate solution with a mass fraction of 7.87g / L, add 10% ammonia solution dropwise until the precipitate disappears, and obtain a silver ammonia solution with a mass fraction of 7.87g / L;

[0029] 4. With 5% 2-(3-carboxy-1-propionylamino)-2-deoxy-D-glucose, 1% fructose aqueous solution and mass fraction are 7.87g / L silver ammonia solution with 10:2: 1 volume ratio, and stirred at 60° C. for 10 h to obtain a nano-silver solution with a particle size of 5-70 nm.

Embodiment 3

[0031] 1. Dissolve 5g of 2-(3-carboxy-1-propionylamino)-2-deoxy-D-glucose in 100ml deionized water to obtain 5% 2-(3-carboxy-1-propionylamino)- 2-deoxy-D-glucose aqueous solution;

[0032] 2. Dissolve 0.001g of sodium borohydride in 100ml of deionized water to obtain a 1% sodium borohydride aqueous solution;

[0033] 3. Configure a silver nitrate solution with a mass fraction of 7.87g / L, add 10% ammonia solution dropwise until the precipitate disappears, and obtain a silver ammonia solution with a mass fraction of 7.87g / L;

[0034] 4. Mix 5% 2-(3-carboxy-1-propionylamino)-2-deoxy-D-glucose aqueous solution and silver ammonia solution with a mass fraction of 7.87g / L at a volume ratio of 10:1, Titrate with 1% sodium borohydride aqueous solution at 40°C and stir until the reaction is complete to obtain a nano-silver solution with a particle size of 5-70 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com