Sealing cover film

A sealing cap and polyethylene layer technology, applied in sealing, closing, packaging, etc., can solve the problems of increasing packaging costs, reducing production efficiency, and high purchase price of zippers, achieving rapid production change, improving production efficiency, and avoiding high processing temperatures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

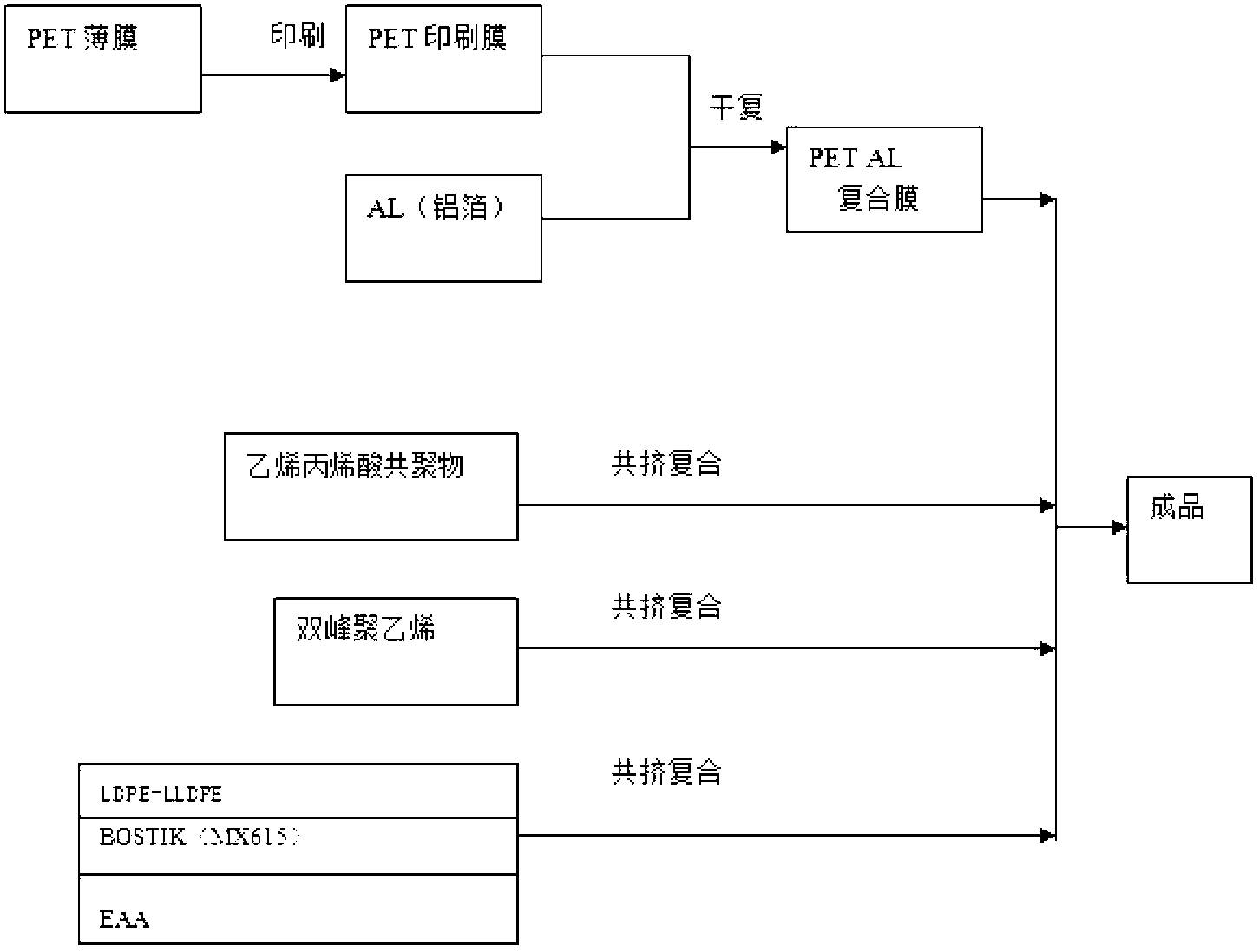

[0035] Depend on image 3 Shown:

[0036] The preparation process of the present invention is

[0037] a. PET printing process: printing on PET to make PET printing film;

[0038] b. The first composite process: composite PET printing film and aluminum foil to make PET / AL

[0039] Composite film;

[0040] C. The second composite process: co-extrude PET / AL composite film with ethylene acrylic acid copolymer, bimodal polyethylene, and composite polyethylene.

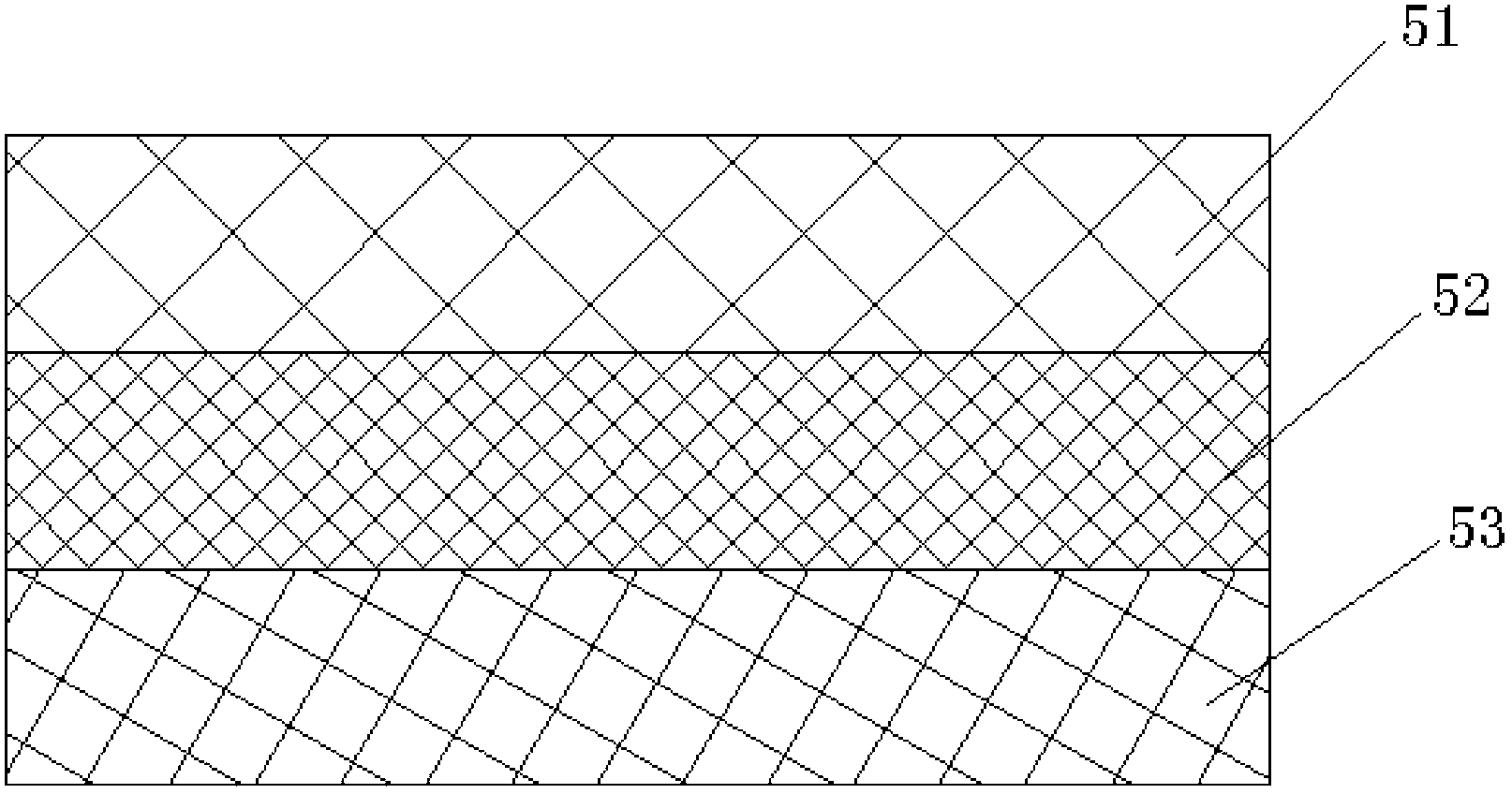

[0041] The composite polyethylene is the co-extrusion composite of the outer layer, Bostik and ethylene acrylic acid copolymer;

[0042] The outer layer is composed of low-density polyethylene and linear low-density polyethylene, and the weight ratio of low-density polyethylene and linear low-density polyethylene is 1:3;

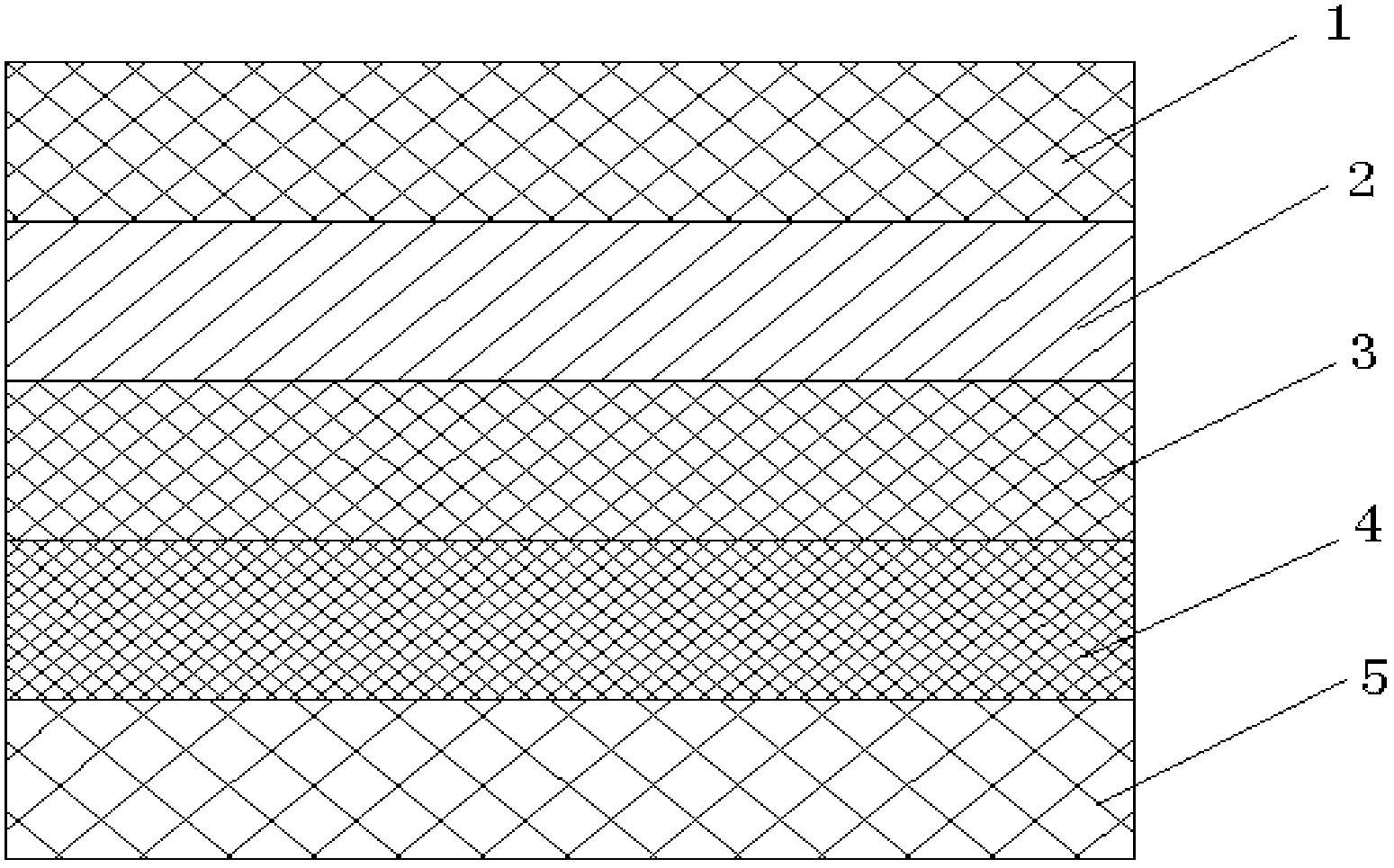

[0043] Such as figure 1 , 2 As shown, the composite film made by the present invention is 12 μm PET layer 1, 7 μm aluminum layer 2, 12 μm ethylene acrylic acid copolymer layer 3, 6 μm bimodal poly...

Embodiment 2

[0046] The outer layer is composed of low-density polyethylene and linear low-density polyethylene, and the weight ratio of low-density polyethylene and linear low-density polyethylene is 1:1; the rest is the same as that of embodiment 1.

[0047] The technical effect of embodiment 1,2 is as follows:

[0048]

[0049] The extrusion layer is composed of ethylene acrylic acid copolymer layer and bimodal polyethylene layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com