Well type cyclic annealing process for bare copper flat wire

A technology of cyclic annealing and flat wire, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of narrow specification range, uneven heat transfer, long heating and cooling time, etc., and achieve wide annealing specification range and simple annealing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

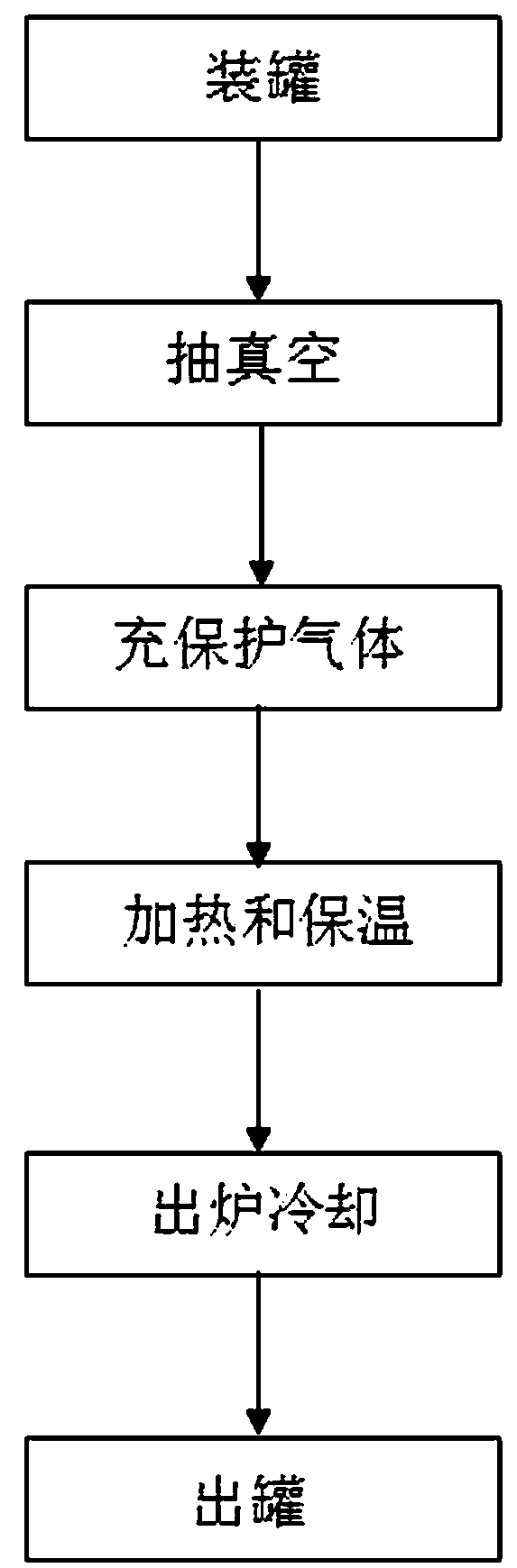

[0017] Such as figure 1 Shown, the present invention comprises the following steps:

[0018] 1) Furnace installation: use the stuffy hot air circulation annealing furnace with the patent number: ZL201120172272.1 as the annealing equipment. When confirming that there is no pressure in the annealing furnace, loosen the bolts on the annealing furnace cover in a symmetrical way, and lift the annealing furnace Put the furnace cover on the designated support; use related tools to lift the iron plate with the bare copper wire core and turn it over 90 degrees, and generally put 2 to 5 coils of wire in each furnace; the uppermost layer of iron in the annealing furnace A part of unoxidized bare copper wire should be placed on the plate; when covering the annealing furnace cover, tighten the bolts symmetrically;

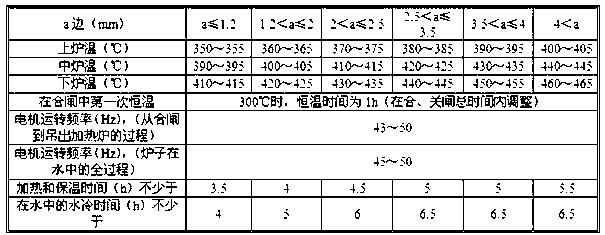

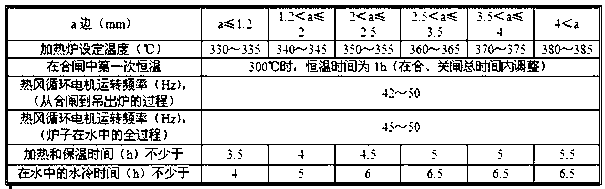

[0019] 2) Vacuuming: Use a leather tube to conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com