A method to improve the dielectric and pyroelectric properties of relaxor ferroelectric thin films

A ferroelectric thin film and pyroelectric technology, which is applied to the electrical properties of lead magnesium niobate-lead titanate (PMN-PT) thin films, improves the dielectric and pyroelectric properties of relaxor ferroelectric thin films, and can solve the problem of high cost , low dielectric and pyroelectric properties, etc., to achieve the effect of simplifying the annealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

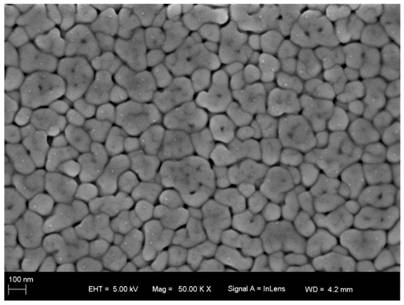

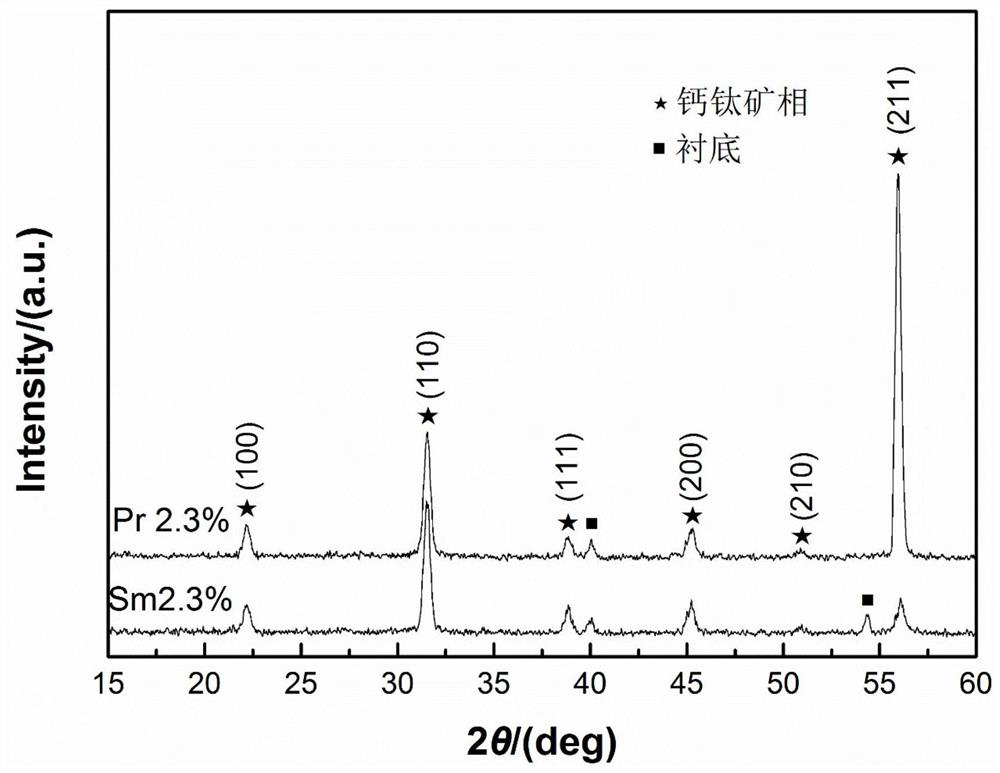

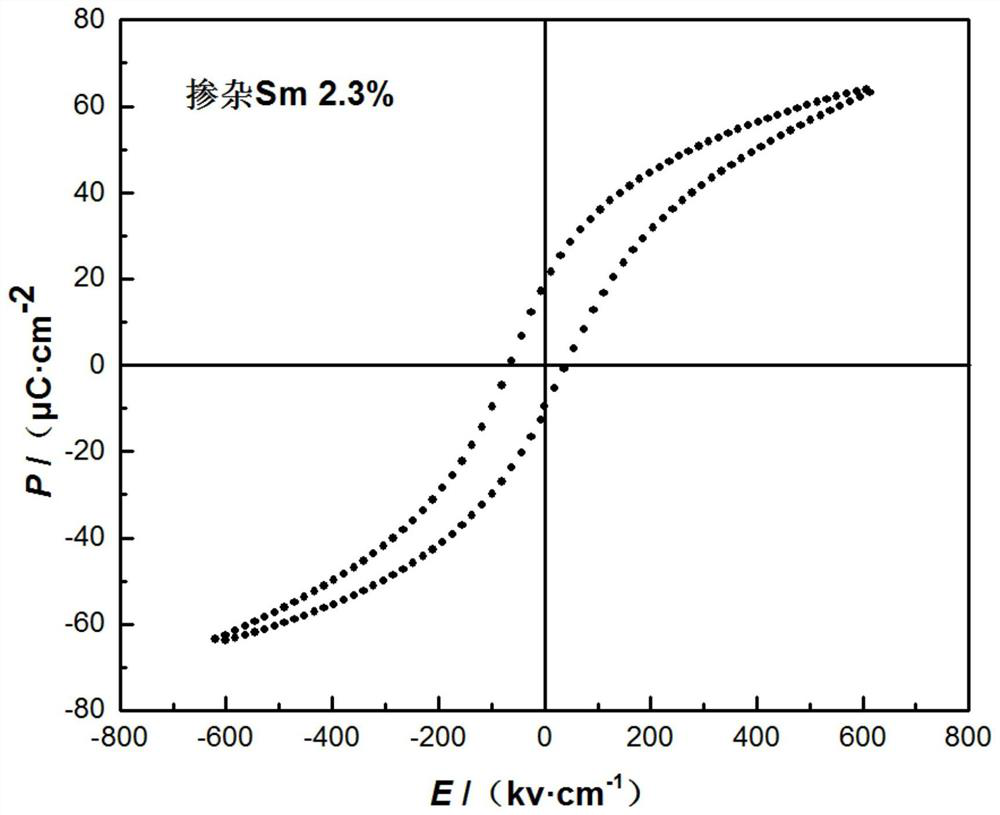

[0027] 30ml 0.3mol / L, 0.7PMN-0.30PT doped 2.3% samarium (Sm) ferroelectric thin film preparation, the steps are as follows:

[0028] (1) Preparation of PMN-PT precursor solution: Weigh lead-containing compounds, magnesium-containing compounds, niobium-containing compounds and titanium-containing compounds according to the amount of each element in the configuration 0.70PMN-0.30PT to prepare:

[0029] Wherein: Preparation of lead-containing solution: Weigh 4.28g of lead acetate trihydrate, dissolve it in 10-12ml of ethylene glycol methyl ether solution, and stir it at 60 degrees Celsius to dissolve it without precipitation;

[0030] Preparation of lead-magnesium mixed solution: add 0.48g of magnesium acetate to the lead-containing solution, drop 2-3ml of acetylacetone, and stir at room temperature to obtain a lead-magnesium mixed solution;

[0031] Preparation of lead-magnesium-niobium mixed solution: drop 1.33g of niobium ethoxide and 0.85g of acetylacetone into the lead-magne...

Embodiment 2

[0040]30ml 0.3mol / L, 0.7PMN-0.30PT doped 2.3% praseodymium (Pr) ferroelectric thin film, the steps are as follows:

[0041] (1) Preparation of PMN-PT precursor solution: Weigh lead-containing compounds, magnesium-containing compounds, niobium-containing compounds and titanium-containing compounds according to the amount of each element in the configuration 0.70PMN-0.30PT to prepare:

[0042] Wherein: Preparation of lead-containing solution: Weigh 4.28g of lead acetate trihydrate, dissolve it in 10-12ml of ethylene glycol methyl ether solution, and stir it at 60 degrees Celsius to dissolve it without precipitation;

[0043] Preparation of lead-magnesium mixed solution: add 0.48g of magnesium acetate to the lead-containing solution, drop 2-3ml of acetylacetone, and stir at room temperature to obtain a lead-magnesium mixed solution;

[0044] Preparation of lead-magnesium-niobium mixed solution: drop 1.33g of niobium ethoxide and 0.85g of acetylacetone into the lead-magnesium mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com