Preparation method and application of chitosan modified talcum powder papermaking filler

A chitosan modification and paper-making filler technology, which is applied in the field of paper-making industry, can solve the problems of increased modification cost and troublesome solvent reuse, and achieve good biocompatibility, simple operation and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The embodiments of the present invention will be described in detail below.

[0079] 2.1 Because filling can reduce costs, improve the optical properties of paper, and at the same time reduce energy consumption and improve paper machine operation, it is widely used by paper companies. At the same time, there are many problems, especially under high filling amount, the main problem is the decrease of paper strength and poor filler retention. In order to overcome the shortcomings of the existing filling and reduce the negative impact of filling, the research on the surface modification of fillers was conceived.

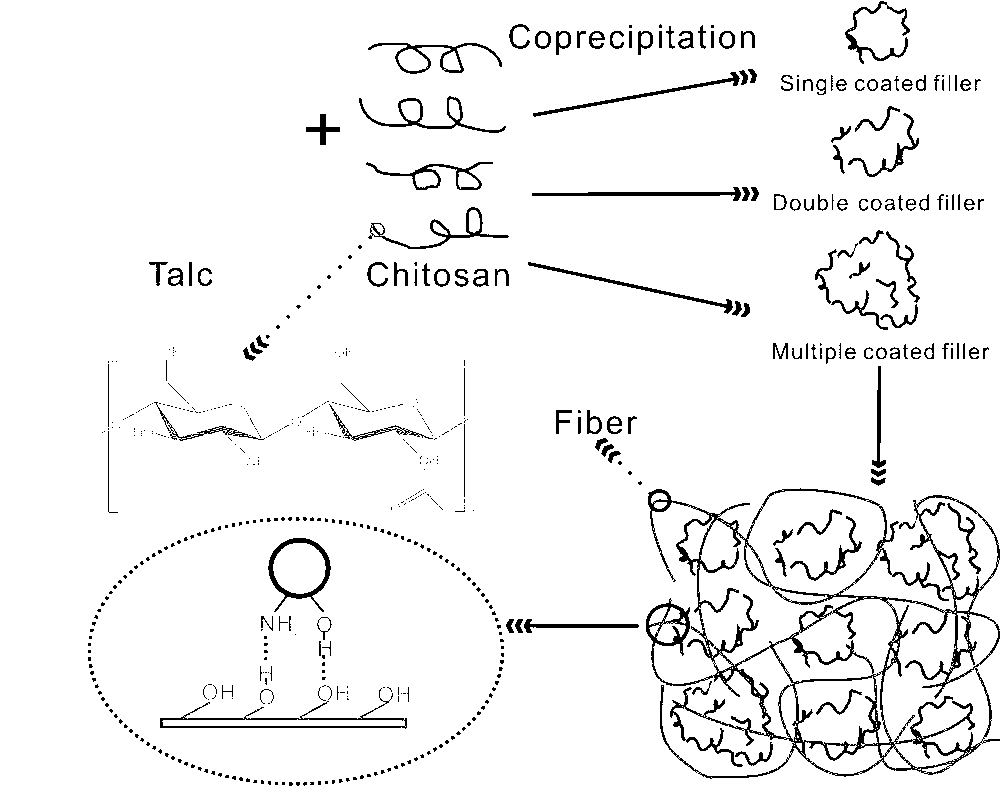

[0080] Chitosan has hydroxyl and amino structures, and can form hydrogen bonds with pulp fibers after paper is made. Using it to modify the surface of fillers can increase the bonding force between fillers and fibers and improve paper performance.

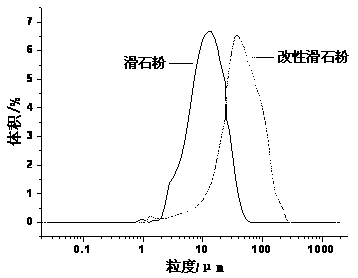

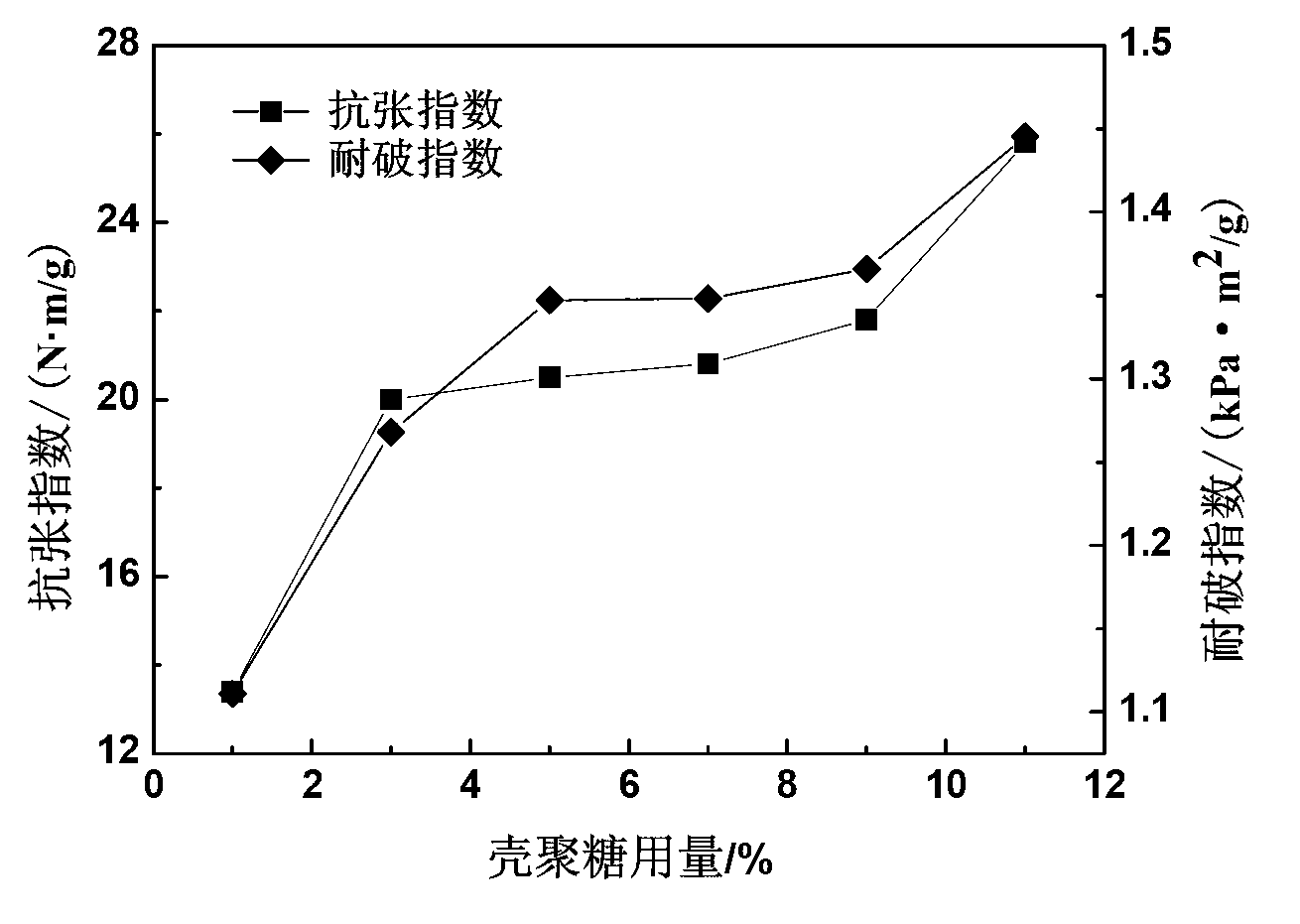

[0081] This part mainly studies the preparation process of chitosan modified talcum powder: investigate the effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com