Composite enzyme beverage and preparation process method thereof

A preparation process and compound enzyme technology, applied in vinegar preparation, food preparation, food science and other directions, can solve the problems of supercooling, single nutrient composition, and inability to extract nutrients, and achieve the effect of enhancing digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

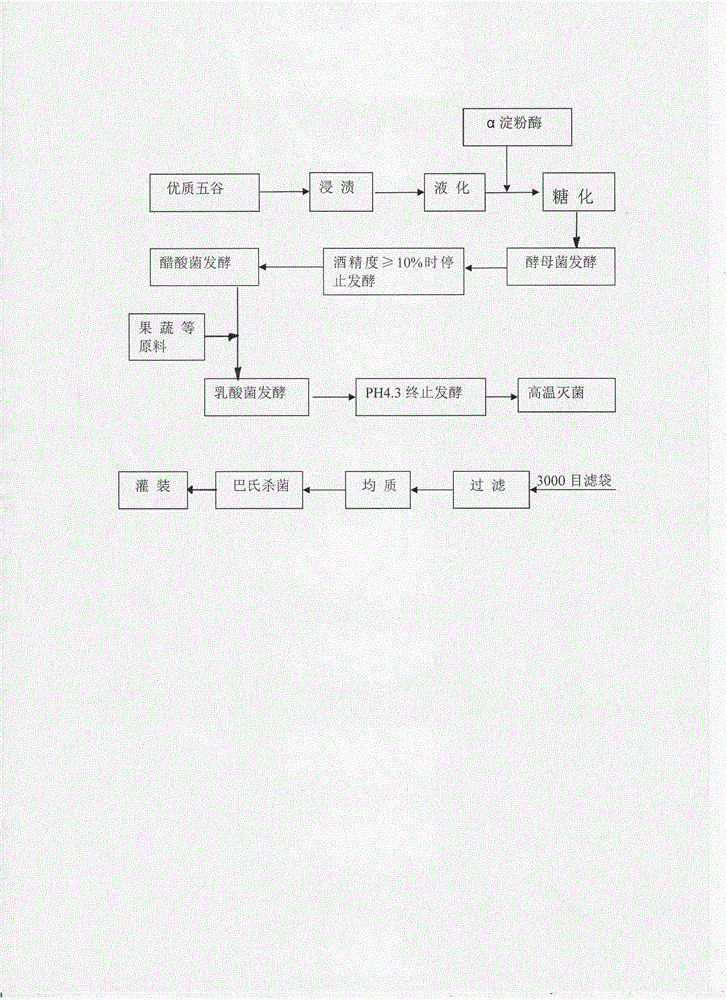

Method used

Image

Examples

Embodiment 1

[0020] Select 10kg of high-quality brown rice, add 20kg of water to fully soak it, then add 70kg of water to refine it, add 200g of calcium chloride, adjust the pH value to 6.4 with sodium carbonate, then add it to the steam pot, and start when it is heated to 40°C Stir, slowly add 300g of a-amylase while heating, keep it for 15-30 minutes when heated to 85°C, until it is completely liquefied, continue to heat to 100°C to inactivate the enzyme, cool down to 60°C, and pour the liquefied brown rice into the fermentation container Add 500g of glucoamylase and stir for 15 minutes, keep warm for 2-4 hours, continue to stir and cool to 36°C, open the lid of the fermentation container, add 100g of active dry yeast, close the lid after stirring well, the fermentation temperature is 30- 35°C, do not start stirring in the middle of fermentation, the fermentation time is 48-72 hours, stop fermentation when the alcohol content reaches ≥10%. Put 100g of acetic acid bacteria into the mixtur...

Embodiment 2

[0023] Select 10kg of high-quality buckwheat, add 20kg of water to fully soak it, then add 70kg of water to refine it, add 200g of calcium chloride, adjust the pH value to 6.4 with sodium carbonate, then add it to the steam pot, and start when it is heated to 40°C Stir, add 300g of a-amylase slowly while heating, keep it for 15-30 minutes when heated to 85°C, until it is completely liquefied, continue to heat to 100°C to inactivate the enzyme, cool down to 60°C, pour the liquefied buckwheat into the fermentation container Add 500g of glucoamylase and stir for 15 minutes, keep warm for 2-4 hours, continue to stir and cool to 36°C, open the lid of the fermentation container, add 100g of active dry yeast, close the lid after stirring well, the fermentation temperature is 30- 35°C, do not start stirring in the middle of fermentation, the fermentation time is 48-72 hours, stop fermentation when the alcohol content reaches ≥10%. Put 100g of acetic acid bacteria into the mixture, cul...

Embodiment 3

[0026] Select 10kg of high-quality brown rice, add 20kg of water to fully soak it, then add 70kg of water to refine it, add 200g of calcium chloride, adjust the pH value to 6.4 with sodium carbonate, then add it to the steam pot, and start when it is heated to 40°C Stir, add 300g of a-amylase slowly while heating, keep it for 15-30 minutes when heated to 85°C, until it is completely liquefied, continue to heat to 100°C to inactivate the enzyme, cool down to 60°C, and pour the liquefied brown rice into the fermentation container Inside, add 500g of glucoamylase and stir for 15 minutes, keep warm for 2-4 hours, continue to stir and cool to 36°C, open the lid of the fermentation container, add 100g of active dry yeast, close the lid after stirring well, the fermentation temperature is 30- 35°C, do not start stirring in the middle of fermentation, the fermentation time is 48-72 hours, stop fermentation when the alcohol content reaches ≥10%. Put 100g of acetic acid bacteria into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com