Application of raney nickel as slurry reactor to synthesize methane catalyst

A technology for synthesizing methane and a catalyst is applied in the application field of Raney nickel as a slurry bed methanation catalyst, which can solve problems such as increased catalyst wear, high reaction temperature, and catalyst pore structure damage, and achieves the effect of avoiding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

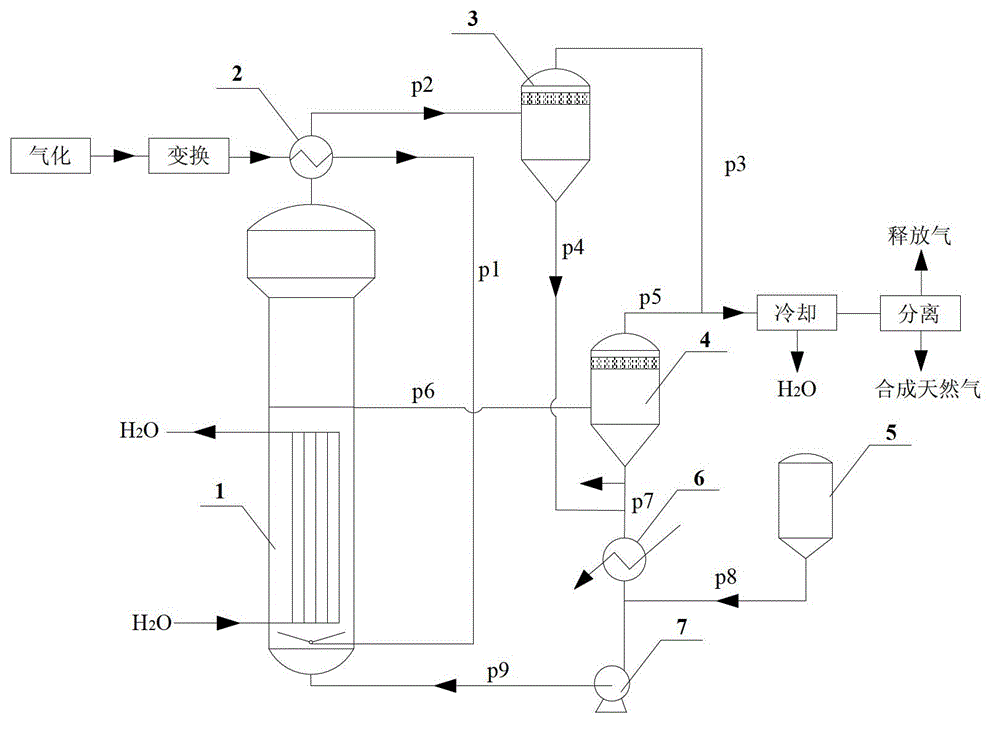

Method used

Image

Examples

Embodiment 1

[0031] Ni 93 al 5 Mo 2 Raney nickel catalyst is mixed with paraffin in the catalyst storage tank, and the control Raney nickel concentration is 2wt%, and is pressed in the slurry state bed methanation reactor by circulation pump 7 from the bottom through pipeline p1, then passes into (V% ): H 2 66.53%, CH 4 12%, N 2 1%, CO 19.47%, CO 2 1% synthesis gas, the pressure is raised to 1Mpa, and the temperature is raised to 250°C to start the reaction. The air velocity of the feed gas is 1000L / (h kg), and the tail gas enters the gas-liquid separator I from the top of the reactor through the pipeline p3. The liquid components and catalysts entrained in the tail gas are discharged from the bottom of the separator I, and merged with the pipe p8 through the pipeline p5, and the tail gas is discharged from the top of the gas-liquid separator I to obtain synthetic natural gas after cooling and purification. During the methanation reaction, the inert liquid phase medium containing...

Embodiment 2~11

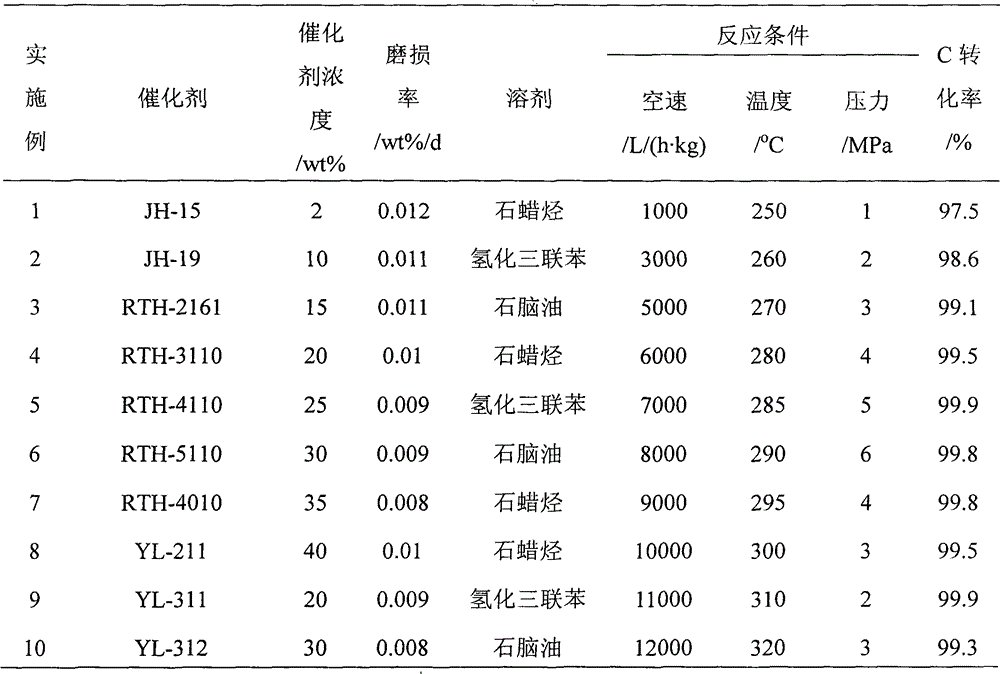

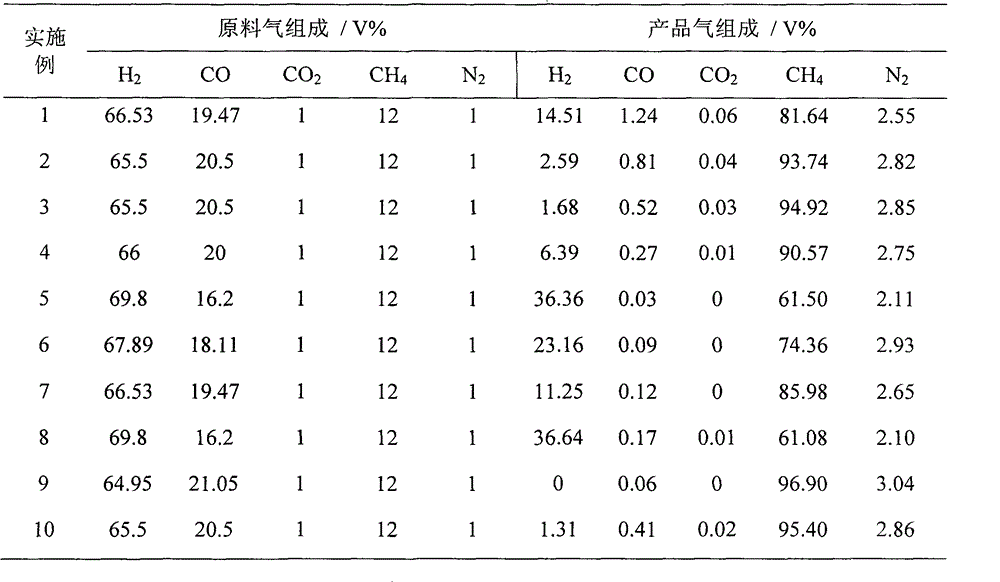

[0033] On the basis of Example 1, Examples 2-11 adjusted the catalyst type, the concentration of the catalyst in the slurry bed methanation reactor, the type of inert liquid medium, the reaction gas space velocity, the reaction temperature, and the reaction pressure factors. , see attached table 1 for specific data and results, and attached table 2 for composition of feed gas and product gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com