Novel air-cooled condenser for brewing wine

An air-cooled condenser, a new technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of poor cooling effect, complicated structure of water-cooled equipment, and inability to produce high-temperature wine, etc., to maintain traditional flavor and simple structure , clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

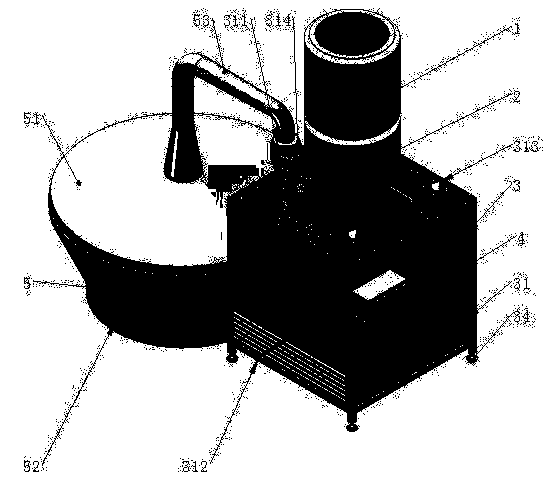

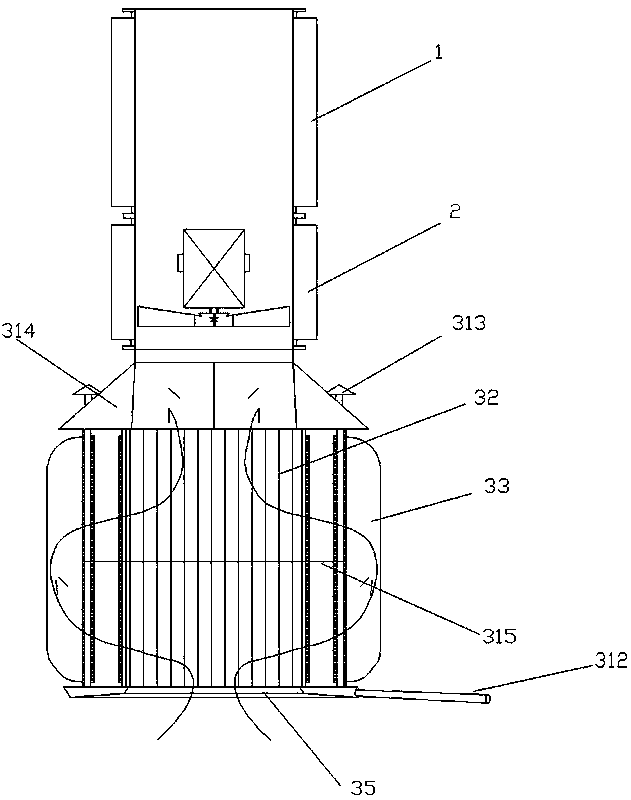

[0028] Such as Figure 1 to Figure 3 Shown is a preferred embodiment of the present invention.

[0029] Such as figure 1 As shown, a new type of air-cooled condenser for brewing, including a muffler 1, a fan 2 and a cooling chamber 3, which are connected in sequence from top to bottom. There is a distiller's grain vapor inlet 311 above the cooling chamber, and an air inlet below the cooling chamber. The above-mentioned structure is the prior art in this field, and will not be described in detail this time. The noise of the fan is the noise source of the equipment. In order to reduce the environmental pollution of the workshop, a muffler is installed at the air outlet to control the noise of the fan at about 60dB (A). In the embodiment, a fan with multiple blades and low noise is selected to reduce the noise of the fan to 60 dB(A).

[0030] Such as figure 2 , image 3 As shown, the cooling chamber includes an outer frame 31 and a plurality of rows of heat exchange tubes 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com