Complete multichannel white body welding spot detection system

A solder joint detection, multi-channel technology, applied in the processing of detection response signals, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as low detection efficiency and inability to meet production needs, and achieve high detection efficiency and improved Efficiency, the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

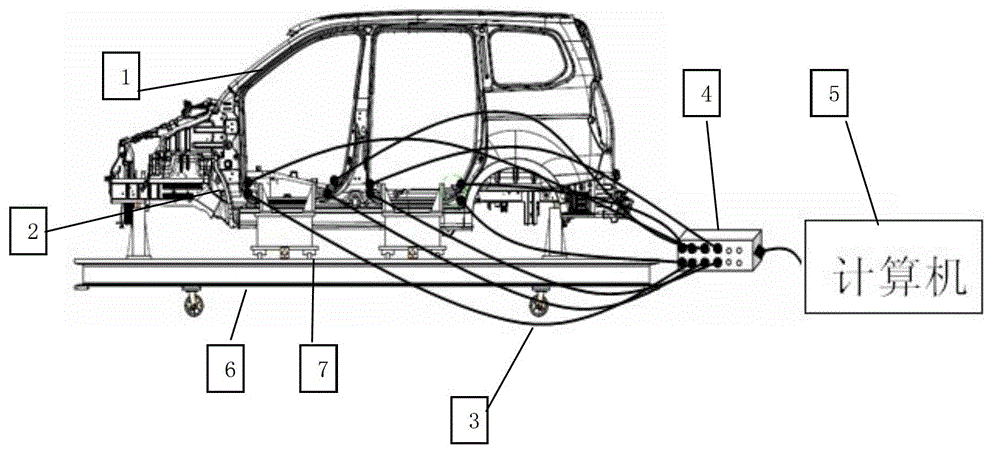

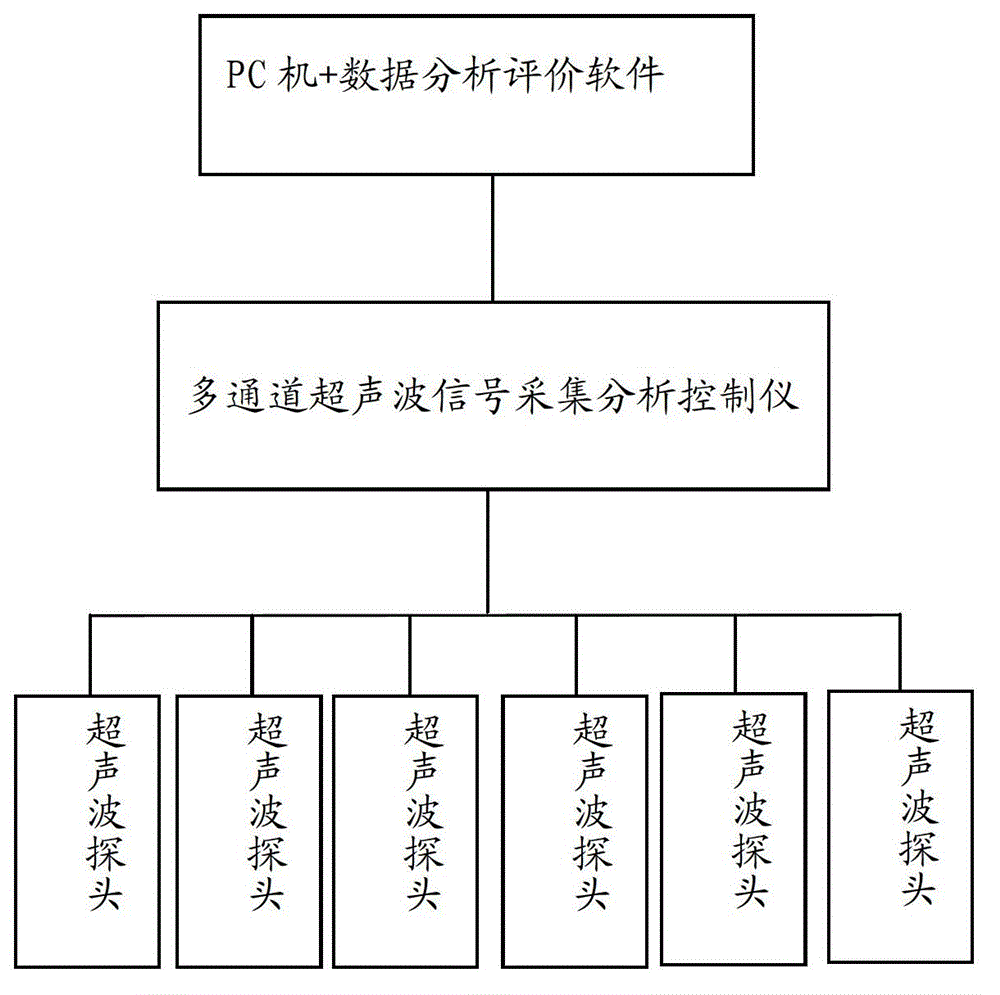

[0033] see Figure 1-2 , which shows a whole set of multi-channel body-in-white welding spot inspection system of the present invention. Wherein, the body-in-white welding assembly 1 is fixed by the positioning pins 11 of the body-in-white of the stand 6 (see figure 2 ), a plurality of ultrasonic probes 2 are attached to the body-in-white welding assembly 1 through the probe fixture 7 slidably fixed on the stand 6, and the ultrasonic probes 2 are connected to the multi-channel signal acquisition and analysis through the connecting cable 3 The controller 4 is connected to the computer 5 through the connection cable 3 for multi-channel signal acquisition and analysis.

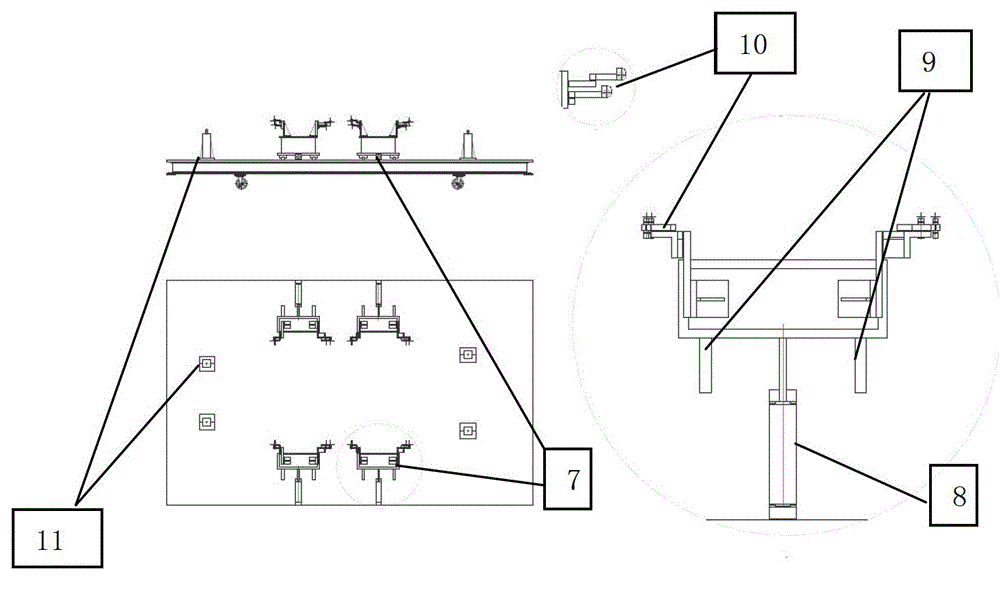

[0034] The probe fixture 7 of the present invention includes a cylinder 8 , a linear guide rail 9 and a probe locking device 10 . Wherein the ultrasonic probe is det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com