Methods and system for controlling wind turbine generator to be power-off and power-on

A technology for wind turbines and units, applied in wind power generation, single-network parallel feeding arrangements, etc., can solve problems such as short circuit, damage to unit equipment, and shorten the service life of components, so as to prevent damage to zero components, prevent unit power-off, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

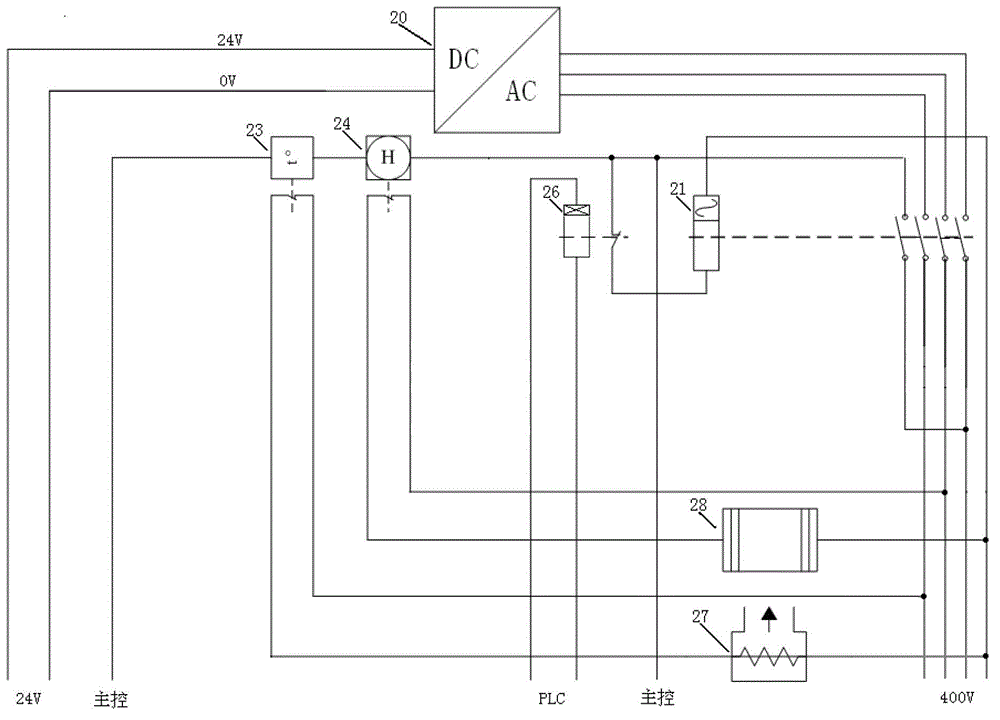

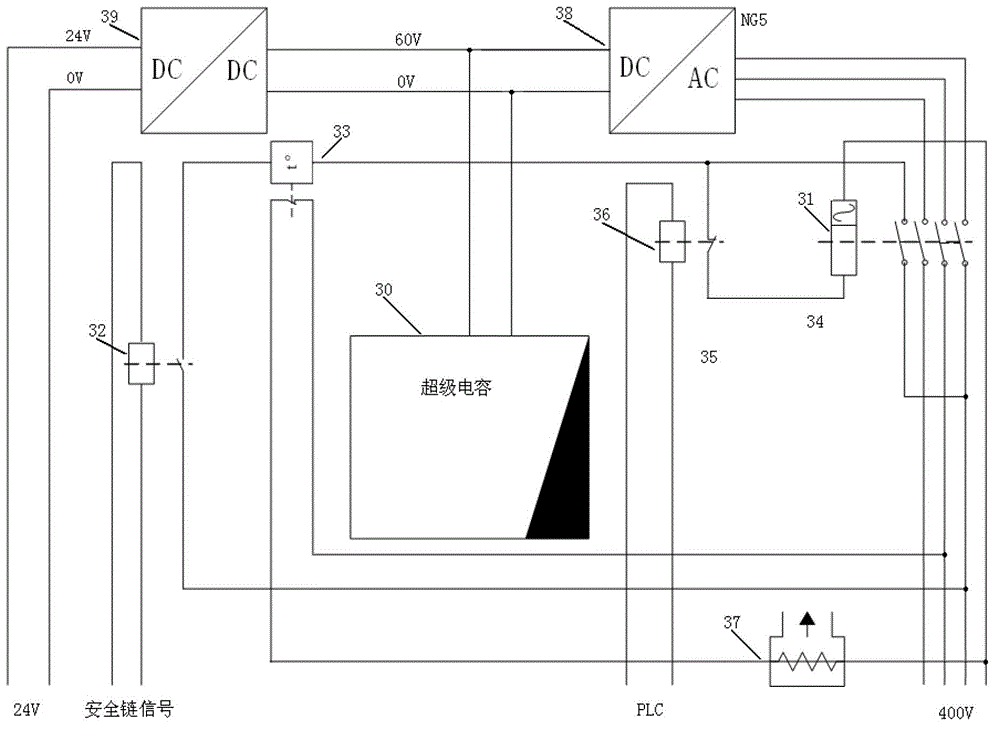

[0029] The system for controlling power-off and power-on of wind turbines in the present invention includes a main control cabinet circuit, a nacelle circuit and a pitch control system circuit.

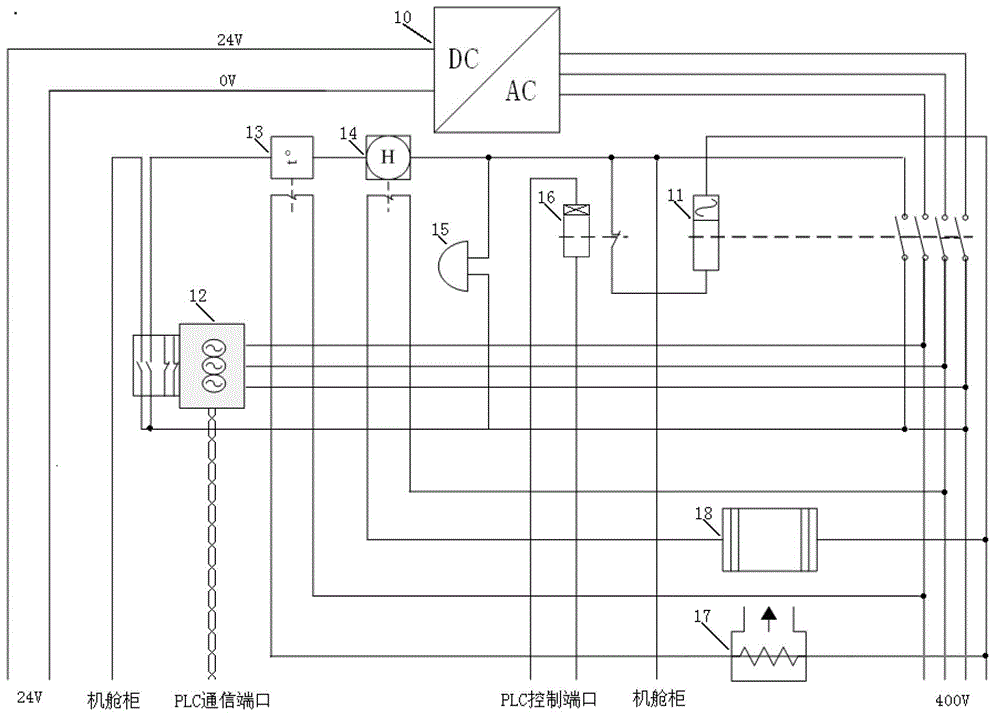

[0030] Among them, see figure 1 As shown, the main control cabinet circuit of the present invention is provided with a power-off relay 11 between the main control power supply and the AC / DC power conversion module 10, and the power-off relay 11 is connected with a grid-side power supply detection module 12, a temperature detection module 13, Humidity detection module 14, power-on button 15 and PLC relay 16.

[0031] The AC / DC power conversion module 10 converts the 400V power of the main control into 24V DC to provide 24V control power for the unit.

[0032] Power-off relay 11, power-off and power-on of the 24V power supply of the control circuit, controlled by the grid-side power detection module 12, temperature detection module 13, humidity detection module 14, power-on button 15 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com