Preparation method of active carbon-supported ruthenium-based ammonia synthesis catalyst

A technology of activated carbon and catalyst, which is applied in the field of preparation of activated carbon-supported ruthenium-based ammonia synthesis catalyst, which can solve the problems of residual chloride ions and influence on catalyst production efficiency, and achieve the effects of uniform distribution, stable performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

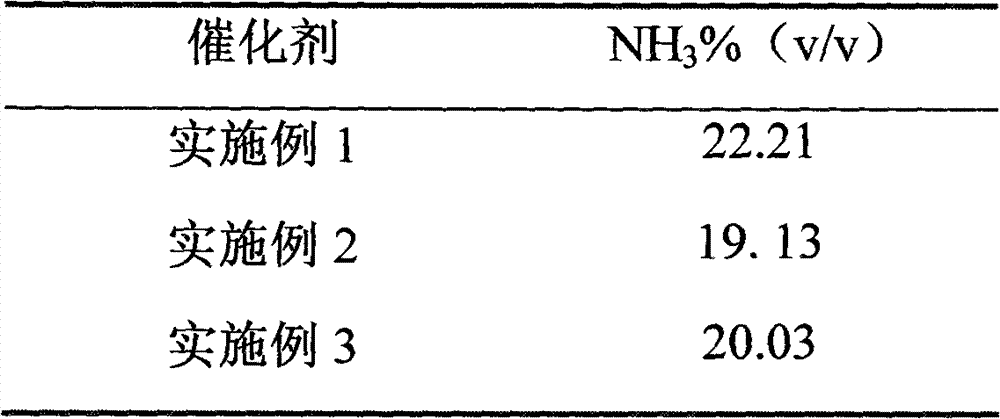

Examples

Embodiment 1

[0017] Take 500g BET specific surface area as 1050m 2 / g coconut shell charcoal, placed in the scrubber and washed with flowing pure water to pH=7; the removed activated carbon is dried in a drying oven at 120℃ for 4h, and then placed in a high-temperature oven, under the protection of inert gas Treat it at 1800~1900℃ for 2h, after the temperature is lowered to room temperature, take it out and place it in the reaming furnace, and pass in oxygen and CO 2 The mixed gas composed of nitrogen, water vapor gas is treated at 380-460℃ for 16h and then lowered to room temperature for later use.

[0018] Take 100g of activated carbon that has been treated as above, and use Ba(NO 3 ) 2 And Mg(NO 3 ) 2 The mixture aqueous solution is impregnated. Based on the weight of the carbon carrier, the Ba content of the carrier is controlled to be about 4wt%, and the Mg content is about 0.7wt%; after drying at 80~110℃ to remove water under infrared light, use RO 2 (NH 3 ) 2 (NO 3 ) 2 +KNO 3 Ba(NO 3 ) ...

Embodiment 2

[0020] Repeat the process of Example 1, but put the barium immersion operation in the RO 2 (NH 3 ) 2 (NO 3 ) 2 +KNO 3 Do it later.

Embodiment 3

[0022] Repeat the process of Example 1, but put the barium immersion operation in RO 2 (NH 3 ) 2 (NO 3 ) 2 +KNO 3 Before.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com