Filling method of sulfur recovery catalyst

A catalyst and sulfur recovery technology, which is applied in the preparation/purification of sulfur, etc., can solve the problems of poor catalyst strength, rapid catalyst deactivation, and affecting device operation, etc., achieve strong anti-coking ability, eliminate bottleneck constraints, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

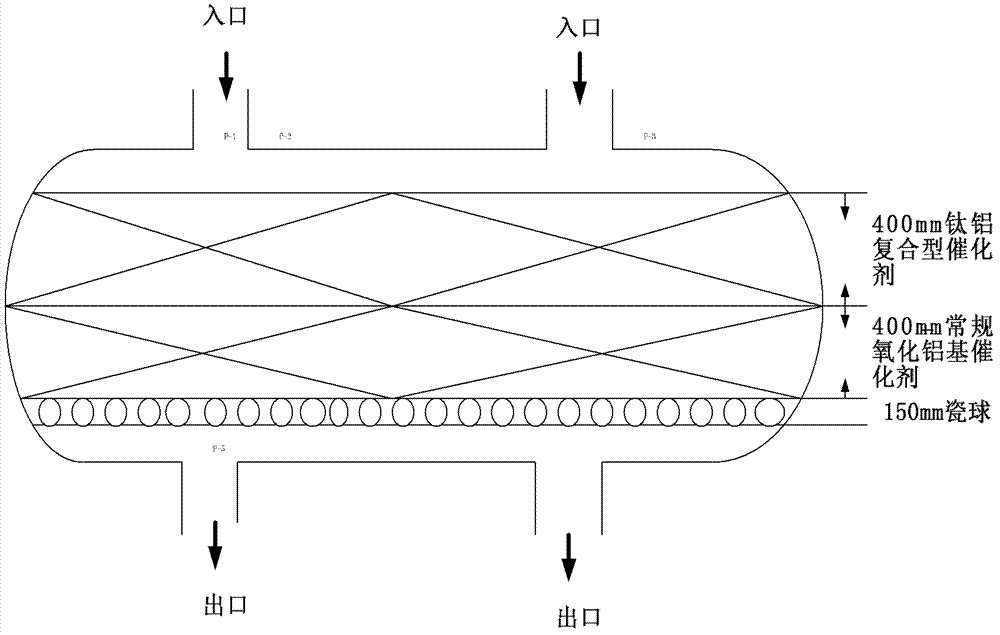

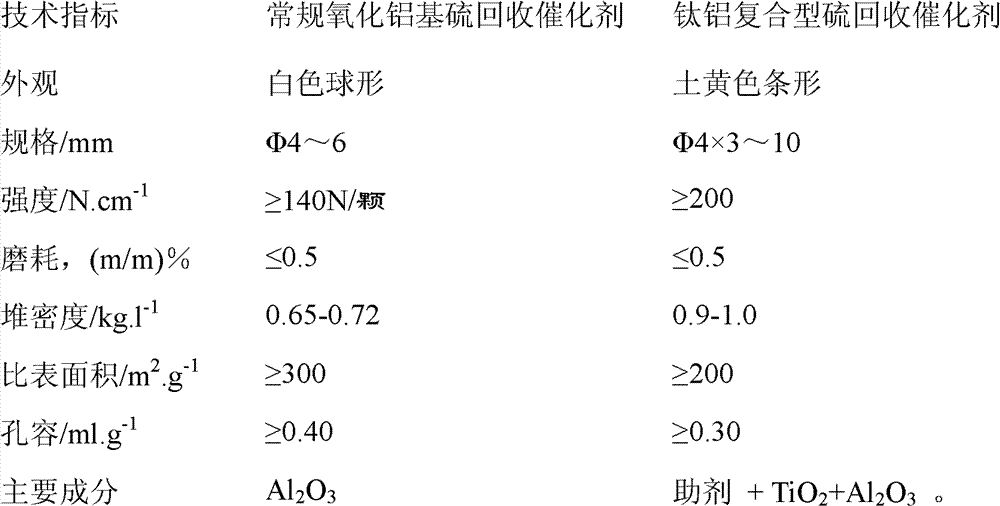

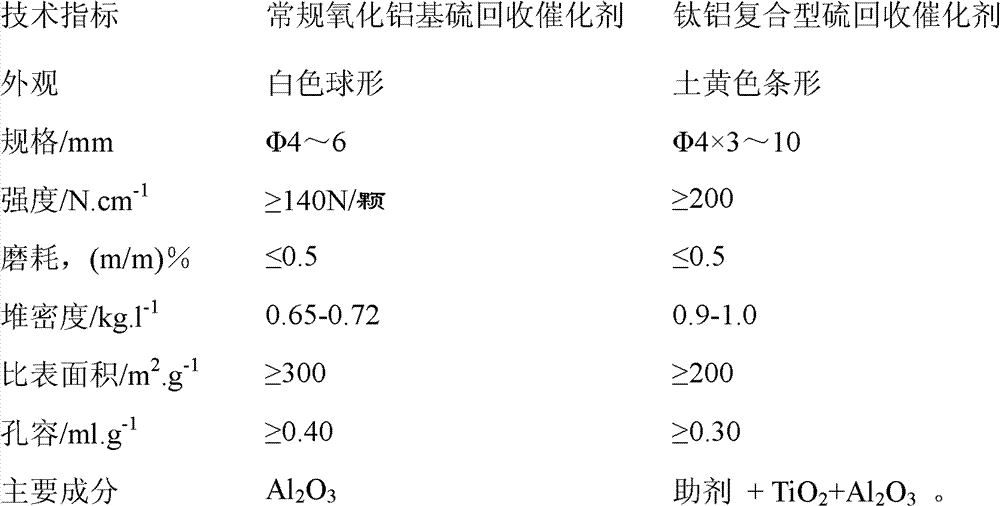

[0033] The invention is applied to a certain sulfur recovery device, and the hydrocarbon gas volume content in the feed gas of the device is 4-30%, which is higher than the normal design value of the device. The conventional alumina-based sulfur recovery catalyst developed by the Research Institute of Sinopec Qilu Branch and the titanium-aluminum composite sulfur recovery catalyst developed by the Research Institute of Sinopec Qilu Branch are used for composite packing. The catalyst gradation scheme of the present invention is as follows: two-stage sulfur production reactor The height of the catalyst is 800mm; the upper part of the primary converter is filled with a 400mm-high titanium-aluminum composite multifunctional sulfur recovery catalyst, a total of 20t, and the lower part is filled with a 400mm-high conventional alumina-based sulfur recovery catalyst, a total of 14t; the secondary conversion The catalyst loading scheme of the converter is the same as that of the primary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com