Airlift oxidation ditch type membrane bioreactor

A membrane bioreactor, oxidation ditch technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., to achieve the effect of increasing volume load, saving power consumption, and high solid-liquid separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

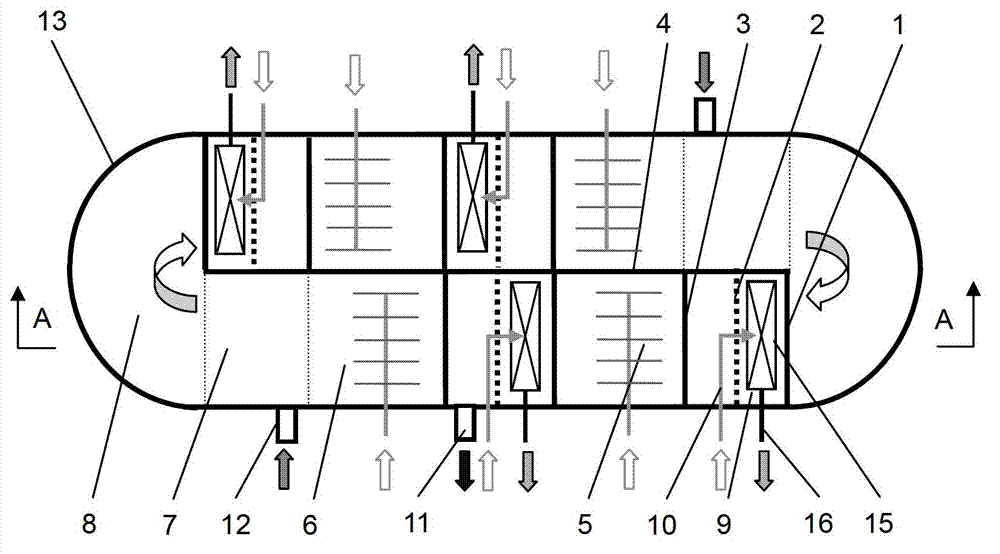

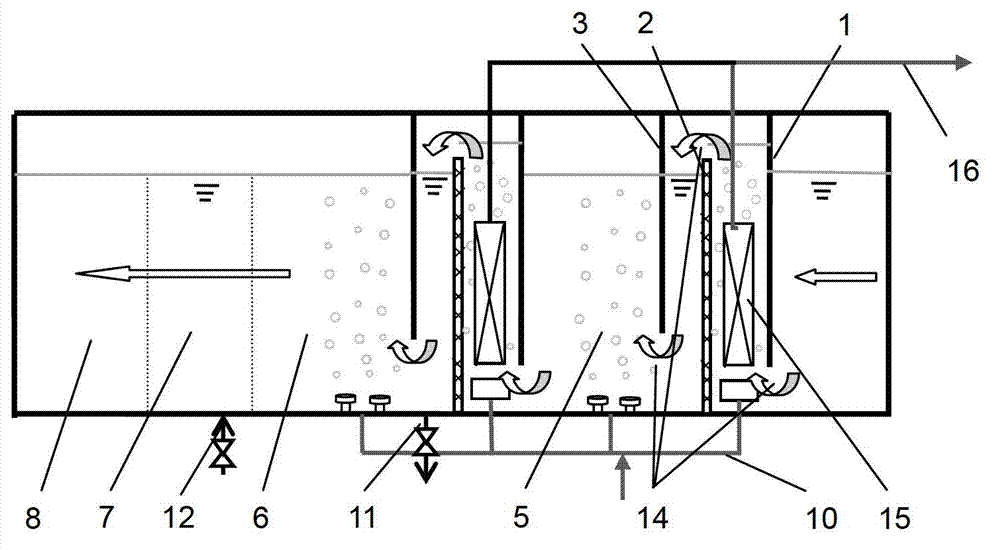

[0021] Embodiment 1, air-lift oxidation ditch type membrane bioreactor

[0022] The structure of the airlift oxidation ditch type membrane bioreactor in this embodiment is as follows figure 1 and figure 2 As shown, it includes an oxidation ditch surrounded by outer ditch walls 13, and a partition wall 4 is arranged inside the oxidation ditch; the reactor includes two treatment units, and the two treatment units are connected. Each treatment unit sequentially forms anoxic zone 7, anaerobic zone 8 and aerobic zone 6 along the water flow direction; wherein the aerobic zone includes 2 aeration sections; Part of the first aeration zone 9 and the second aeration zone 5 surrounded by the first baffle plate 1; a third baffle plate 3 is provided between the first aeration zone and the second aeration zone; along the direction of water flow The first aerated zone is adjacent to the anaerobic zone. There is a second baffle 2 in the first aeration area, and the second baffle divides t...

Embodiment 2

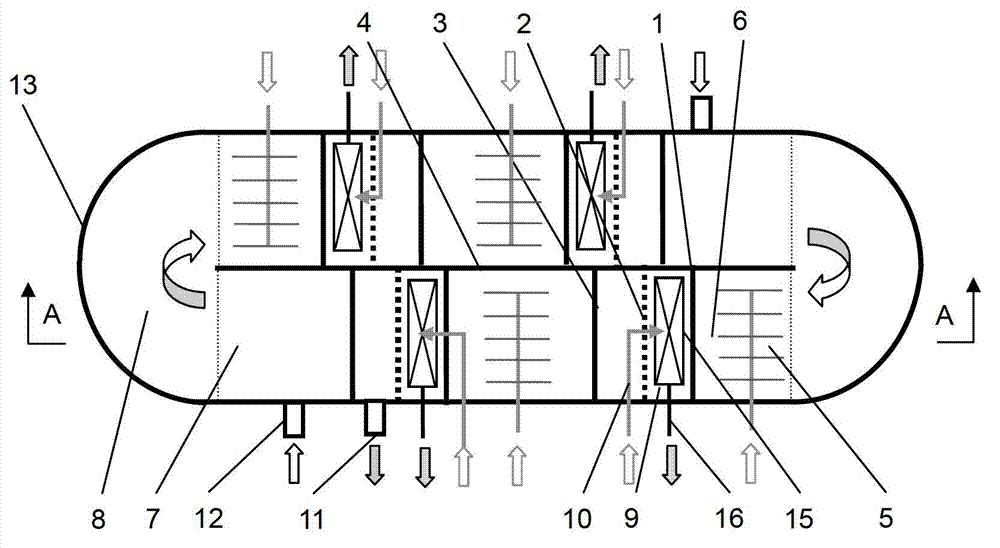

[0027] Embodiment 2, air-lift oxidation ditch type membrane bioreactor

[0028] The structure of the airlift oxidation ditch type membrane bioreactor in this embodiment is as follows image 3 and Figure 4 As shown, its structure is basically the same as that of Example 1, except that along the direction of water flow, the second aeration zone is adjacent to the anaerobic zone, and the membrane used in the membrane module is a microfiltration membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com