Vinyl chloride monomer polymerization reaction system reaction termination method

A vinyl chloride monomer and polymerization reaction technology, which is applied in the field of reaction termination of vinyl chloride monomer polymerization reaction system, can solve the problems of insignificant improvement of thermal stability of resin, low efficiency of polymerization termination, and limited improvement of thermal stability performance, etc., to achieve Excellent thermal stability effect, rapid polymerization termination effect, scientific and reasonable termination method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

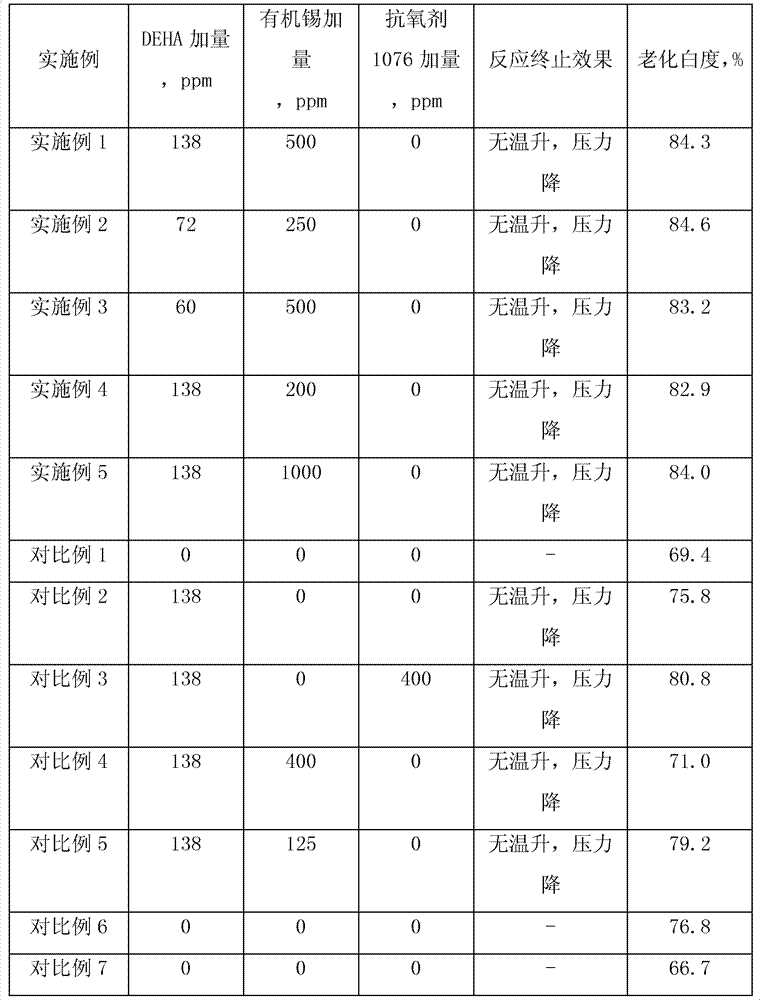

Examples

Embodiment 1

[0040] The polymerization reaction was carried out in a stainless steel reactor with a volume of 5 L equipped with two-layer flat paddles.

[0041] The polymerization formula is as follows:

[0042] raw material name

Dosage / kg

VCM

1.45

DW

2.10

PVA(I)

0.0002

E50

0.00028

PVA(II)

0.00046

TAPP

0.0006

TBPND

0.0003

NG

0.00018

NaOH

0.000065

DEHA

0.0002

OE-Sn

0.00725(500ppm)

[0043] Note:

[0044] VCM: vinyl chloride monomer.

[0045] DW: desalinated water.

[0046] PVA (I): polyvinyl alcohol, alcoholysis degree 80% (mole fraction), viscosity 48mPa.s (measured at 20°C, 4% concentration).

[0047] PVA(II): polyvinyl alcohol, alcoholysis degree 45% (mole fraction), viscosity 90mPa.s (measured at 25°C, 35% concentration).

[0048] E50: hydroxypropyl methylcellulose, with a methoxy substitution degree of 25%, a hydroxyprop...

Embodiment 2

[0059] Adopt the polymerization reactor identical with embodiment 1, used formula is as follows:

[0060] raw material name

Dosage / kg

VCM

1.53

DW

1.82

PVA(I)

0.00061

E50

0.00106

PVA(II)

0.00019

ACPND

0.00026

EHP

0.00078

NaOH

0.000048

DEHA

0.00011

OE-Sn

0.00382(250ppm)

[0061] Note:

[0062] VCM: vinyl chloride monomer.

[0063] DW: desalinated water.

[0064] PVA (I): polyvinyl alcohol, alcoholysis degree 80% (mole fraction), viscosity 48mPa.s (measured at 20°C, 4% concentration).

[0065] PVA(II): polyvinyl alcohol, alcoholysis degree 45% (mole fraction), viscosity 90mPa.s (measured at 25°C, 35% concentration).

[0066] E50: hydroxypropyl methylcellulose, with a methoxy substitution degree of 25%, a hydroxypropyl substitution degree of 11.5%, and a viscosity of 50 mPa.s (measured at 20° C. at a concentration of 2%).

[006...

Embodiment 3

[0076] Adopt the polymerization reactor identical with embodiment 1, used formula is as follows:

[0077] raw material name

Dosage / kg

VCM

1.45

DW

2.10

PVA(I)

0.00026

E50

0.00039

LE

0.00026

NG

0.00141

NaOH

0.000145

DEHA

0.000087

OE-Sn

0.00725(500ppm)

[0078] Note:

[0079] VCM: vinyl chloride monomer.

[0080] DW: desalinated water.

[0081] PVA (I): polyvinyl alcohol, alcoholysis degree 80% (mole fraction), viscosity 48mPa.s (measured at 20°C, 4% concentration).

[0082] E50: hydroxypropyl methylcellulose, with a methoxy substitution degree of 25%, a hydroxypropyl substitution degree of 11.5%, and a viscosity of 50 mPa.s (measured at 20° C. at a concentration of 2%).

[0083] LE: azobisisoheptanonitrile.

[0084] NG: 2-mercaptoethanol.

[0085] NaOH: sodium hydroxide.

[0086] DEHA: Diethylhydroxylamine.

[0087] Polymerization condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com