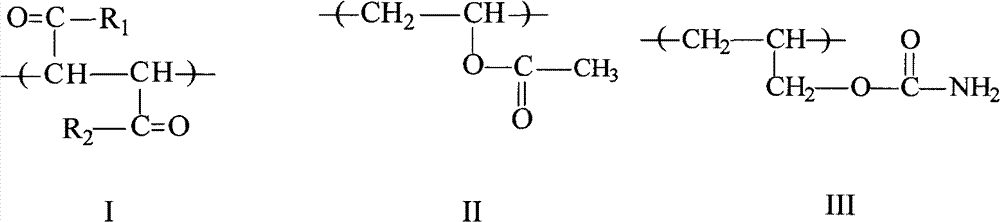

Polymer used in lubricating oil pour point depressing, lubricating oil pour point depressant, and preparation method thereof

A lubricating oil base oil and polymer technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of insignificant effect, improved pour point depressing effect, and insignificant pour point depressing effect of paraffin base oil, etc., to achieve the best Depressing effect, effect of improving shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

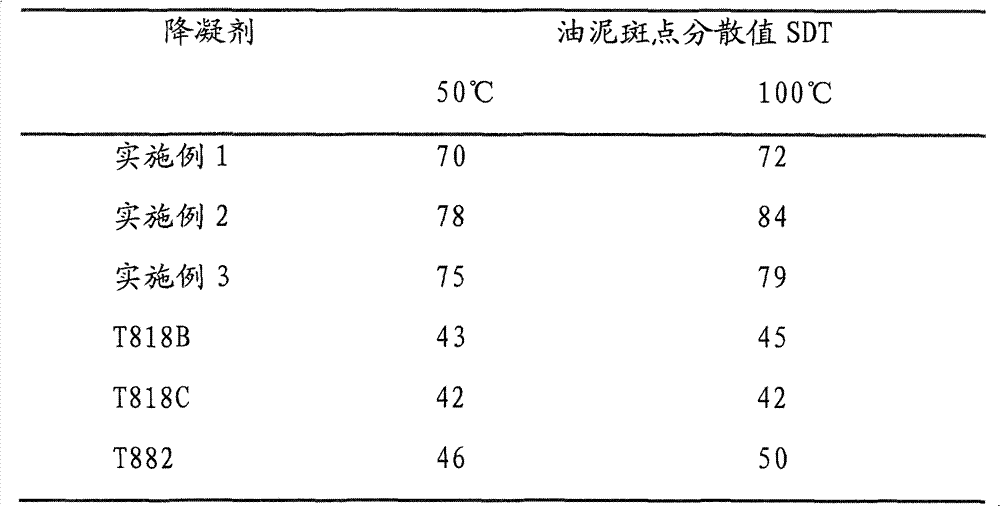

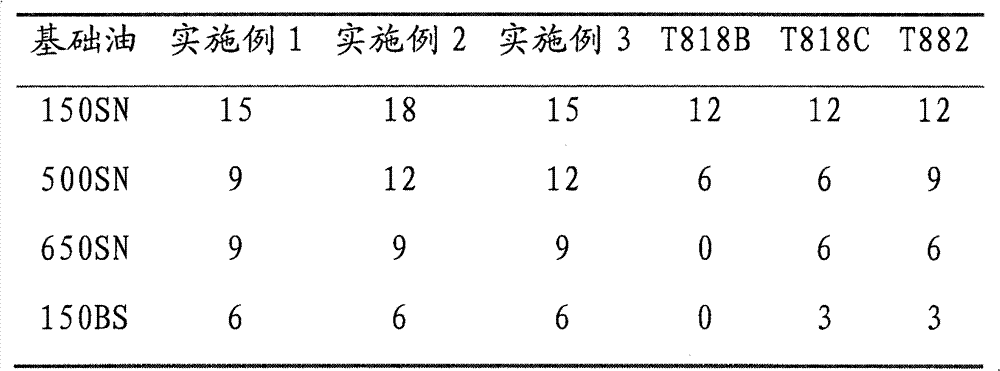

example 1

[0030] Under nitrogen protection, add 42g of 6# hydrogenated oil (produced by Sinopec Shanghai Gaoqiao Petrochemical Company, kinematic viscosity at 100°C to 5.92mm 2 ·s -1 ), 30.0g stearyl fumarate (laboratory synthesis), 10.0g vinyl acetate (Sinopharm Chemical Reagent Co., Ltd.), 2.0g allyl carbamate (laboratory synthesis), 0.2g azobisiso Butyronitrile (produced by Sinopec Yanshan Petrochemical), started stirring and raised the temperature to 70°C. At this time, it was observed that the reactant had obvious exothermic phenomenon. The reaction temperature was controlled at 75°C and reacted for 2 hours. At this time, the material thickened obviously. Then add 0.1g of azobisisobutyronitrile to the reaction system, continue to react for 5 hours, at this time, the material becomes a light yellow viscous liquid, and finally the material is down to room temperature under nitrogen protection, to obtain stearyl fumarate Terpolymer of ester, vinyl acetate and allyl urethane. Among t...

example 2

[0032] Under nitrogen protection, add 46.0 g of 100N hydrogenated oil (produced by Sinopec Shanghai Gaoqiao Petrochemical Company, kinematic viscosity at 100°C to 3.8mm 2 / s), 15.0g lauryl fumarate (laboratory synthesis), 18.0g cetyl fumarate (laboratory synthesis), 8.6g vinyl acetate, 4.0g allyl carbamate (laboratory Synthesis), 0.15g of azobisisobutyronitrile, turn on the stirring and heat up to 70°C. At this time, it is observed that the reactant has obvious exothermic phenomenon. The reaction temperature is controlled at 75°C, and the reaction is 2 hours. At this time, the material is obviously thickened. Then add 0.15g azobisisobutyronitrile to the reaction system, continue to react for 5 hours, at this time, the material becomes a light yellow viscous liquid, and finally the material is down to room temperature under nitrogen protection, to obtain dodecyl fumarate Tetrapolymer of ester, stearyl fumarate, vinyl acetate and allyl carbamate. Among them, dodecyl fumarate ac...

example 3

[0034] Under nitrogen protection, add 45.0 g of PAO No. 4 base oil (produced by China Petroleum Lanzhou Petrochemical Company, with a kinematic viscosity of 3.9 mm at 100° C. 2 / s), 5.0g decyl fumarate (laboratory synthesis), 12.0g myristyl fumarate (laboratory synthesis), 15.0g octadecyl fumarate, 10.0g vinyl acetate, 3.0g Allyl carbamate (synthesized in the laboratory), 0.15g azobisisobutyronitrile, turn on the stirring and raise the temperature to 70°C. At this time, it is observed that the reactant has obvious exothermic phenomenon, the reaction temperature is controlled at 75°C, and the reaction is 2 hours , the material thickened significantly at this time. Then add 0.1g azobisisobutyronitrile to reaction system again, continue to react for 5 hours, at this moment material becomes light yellow viscous liquid, finally material is down to room temperature under nitrogen protection, obtains decyl fumarate, Pentapolymer of myristyl fumarate, stearyl fumarate, vinyl acetate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com