High temperature resisting pressure-sensitive adhesive composition and high temperature resisting pressure-sensitive adhesive tape

A technology of pressure-sensitive tape and composition, which is applied in the field of high-temperature-resistant pressure-sensitive adhesive composition and high-temperature-resistant pressure-sensitive tape, can solve the problems of EVA being non-reactive and unable to withstand high temperatures, and achieve the goal of reducing transportation and storage costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

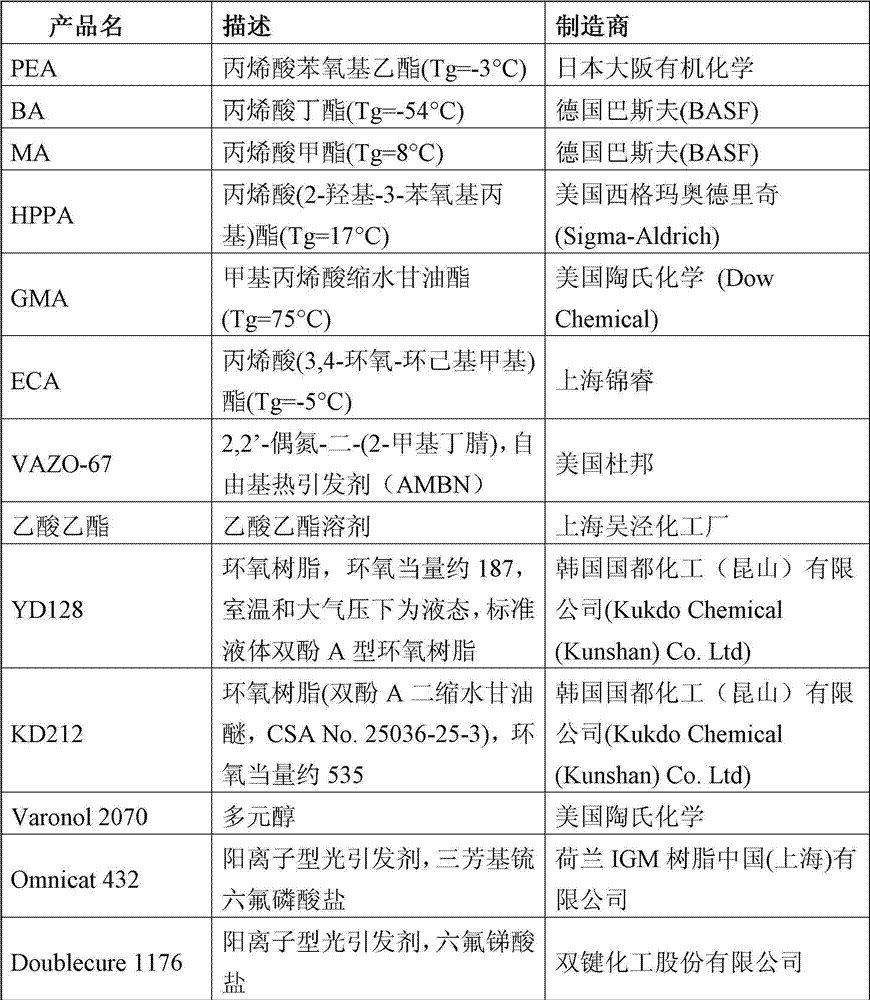

[0079] Example A. Synthesis of reactive polyacrylates

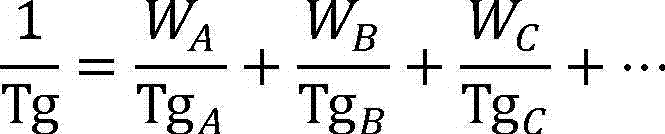

[0080] Weigh all the raw materials shown in Table 2 into a 500ml three-neck flask, stir with a pneumatic stirrer (ZD-J-1 type, Shanghai Zuoda Coating Equipment Co., Ltd.) under N2 purging, and heat up to 60°C After 24 hours of reaction, a light yellow clear viscous liquid (40% solid content) was obtained after cooling. This viscous liquid could be directly used in subsequent experiments without any treatment. The glass transition temperature (Tg) in the table is calculated by FOX equation.

[0081] Table 2.

[0082]

Embodiment B

[0083] Example B. Preparation of Pressure Sensitive Adhesive Composition and Pressure Sensitive Tape

[0084] A pressure-sensitive adhesive composition and a pressure-sensitive adhesive tape were prepared using the samples numbered A-H prepared in Example A, respectively.

Embodiment 1

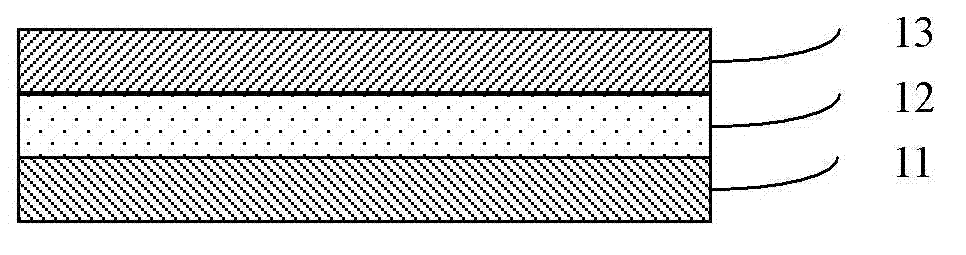

[0091] Add the above-mentioned various components into a 500ml flask after weighing, and stir for 30 minutes with a pneumatic stirrer (ZD-J-1 type, Shanghai Zuoda Coating Equipment Co., Ltd.) to obtain a reactive polymer with a reactive functional group. Acrylate / epoxy hybrid solution. After standing for 20 minutes to eliminate air bubbles, use a comma roll applicator to coat the reactive polyacrylate / epoxy resin hybrid solution on the PET release film coated with silicon release agent on both sides, and control the thickness of the coating to 50 Microns (dried glue thickness). After drying in an oven at 105° C. for 10 minutes to dry the solvent, an ultraviolet light-induced curing pressure-sensitive adhesive tape was obtained, but the initial tack of the adhesive tape was weak.

[0092] After the ultraviolet light-induced curing pressure-sensitive adhesive tape prepared according to this formula is sealed and packaged in a black plastic bag, its shelf life at room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com