Selective plating process for IPMC (Ionic Polymer Metal Composite) drive

A driver and selective technology, applied in the direction of metal material coating process, liquid chemical plating, coating, etc., can solve the problems of poor coating quality, long time consumption, and restrictions on the promotion and use of IPMC materials, etc., to achieve good driving performance, The effect of simple plating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

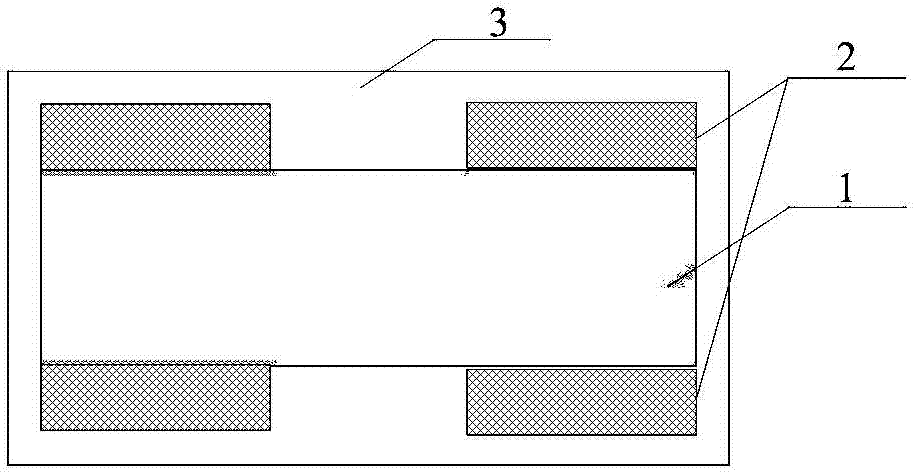

[0022] Embodiment 1 The making of wide isolation line multi-electrode IPMC driver

[0023] Taking the size of 15cm×0.5cm and designing two 3mm-wide isolation lines to divide the material into two sections of multi-electrode IPMC drivers along the length direction as an example, the preparation method based on selective plating includes the following steps:

[0024] 1) Pretreatment of materials

[0025] Use Nafion membrane (or Flemion ion membrane) as the base material of the material, use sandpaper to roughen (sandpaper above 600, lightly polish both surfaces of Nafion membrane), try to make the surface evenly stressed when polishing, pay attention to observe the roughness uniformity , Observing the surface under the light becomes cloudy without obvious bright spots, it can be considered that the polishing has achieved a uniform effect. After the roughened Nafion membrane is heated to 60°C, it is ultrasonically cleaned for 20 minutes to remove its surface particles; then it i...

Embodiment 2

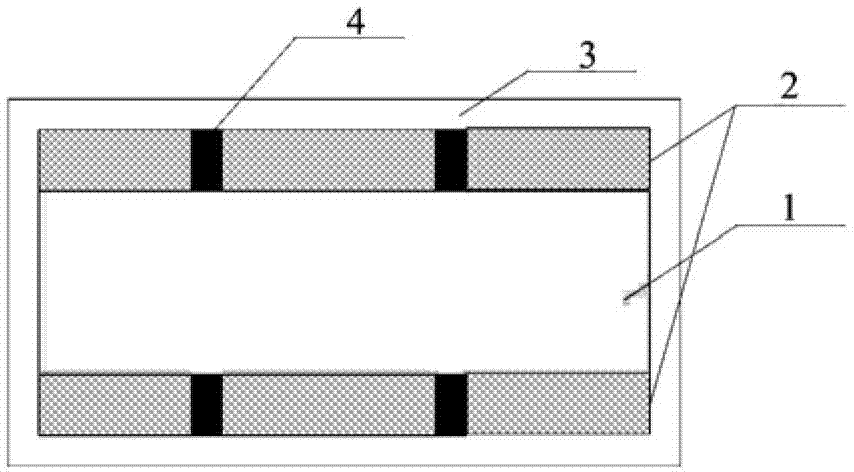

[0032] Embodiment 2 The manufacture of thin isolation line multi-electrode IPMC material driver

[0033] Taking a multi-electrode Ag electrode IPMC driver with a size of 6cm×0.5cm and a barrier line width of 0.5mm as an example, the preparation method based on selective plating includes the following steps:

[0034] 1) The pretreatment process of the material is the same as that of Example 1;

[0035]2) Put the material in 200ml of AgNO with a concentration of 0.03mo / L 3 Soak in the solution for 1 hour, cover the pre-plating area with acid and alkali resistant electroplating tape, expose the non-plating area, and then place it in 0.1mol / L HCl solution for half an hour, and the non-plating area will form a non-conductive width of about 0.5mm AgCl isolated wire ( figure 2 ), peel off the electroplating tape evenly and forcefully, and then soak in deionization for about 10 minutes, and then proceed to the next step of soaking reduction plating.

[0036] 3) Place it again in 0...

Embodiment 3

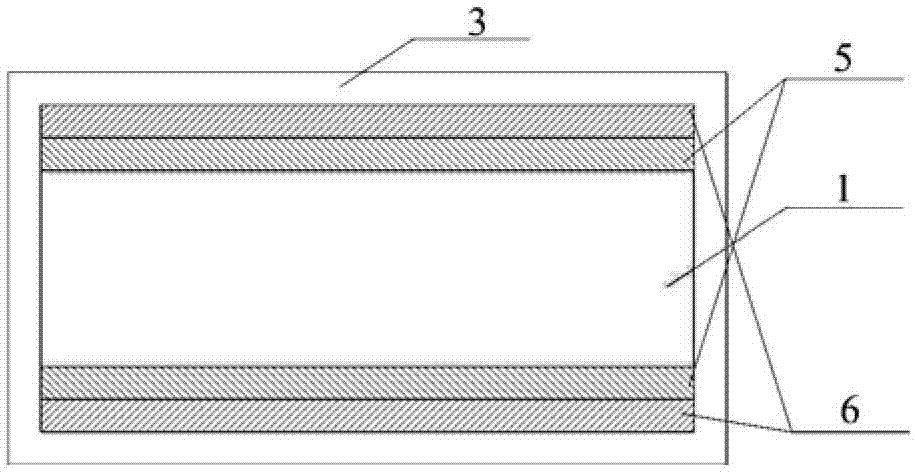

[0041] The making of embodiment 3 composite plating IPMC driver

[0042] Take the palladium and platinum composite electrode type IPMC that is 6cm * 3cm as an example in making the size, the method for composite plating comprises the following steps:

[0043] 1) The pretreatment steps of the material are the same as in Example 1. When making the composite electrode, the activity of the metal needs to be considered, so as to determine the order of plating. First, choose to coat the Nafion film with a metal layer with weak reducibility. Here, choose Platinum-plated electrodes are applied first.

[0044] 2) Place the pretreated material in 0.01mol / L [Pt(NH 3 ) 4 ]Cl 2 Soak in salt for 1-2 hours, soak in deionized water for about 10 minutes, and then place it in NaBH with a concentration of 1mmol / L 4 Soak and reduce in the solution at room temperature, you can see bubbles on the wall of the reaction vessel, when no obvious bubbles appear, it can be considered that the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com