Control device and control method of vacuum drainage pumping station

A vacuum drainage and control device technology, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem that the vacuum degree of the system cannot be maintained within the working range, which is not conducive to the energy-saving operation of the vacuum pump, and the monitoring means do not have the ability to detect the problem. class leaks etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

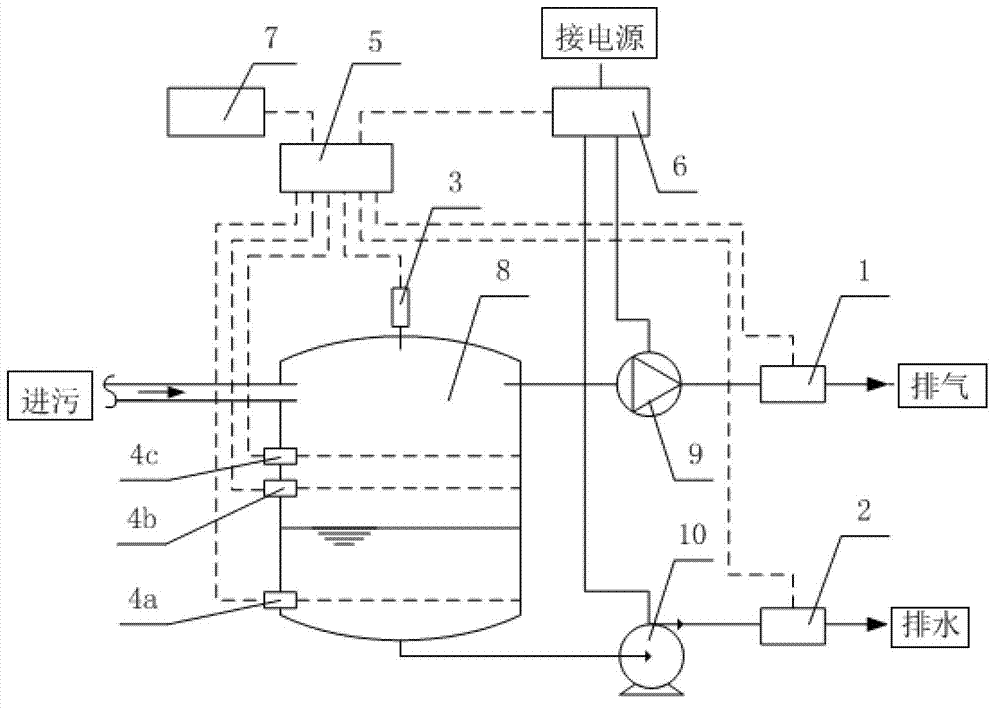

[0058] A control device for a vacuum drainage pumping station, combined with Figure 1 to Figure 6 , including a signal input module, an analysis module 5, an execution module 6, and an information output device 7, the analysis module 5 is respectively connected with the signal input module, the execution module 6, and the information output device 7, and the analysis module 5 is used to make input signals Analyze and judge, transmit the operating instructions of the vacuum pump 9 and the sewage pump 10 to the execution module 6, and transmit system parameters and warning information to the information output device 7; The analysis module 5 issues instructions and controls the operation of the vacuum pump 9 and the sewage pump 10; the information output device 7 is connected with the analysis module 5 for externally displaying system parameters and issuing warning messages.

[0059] The signal input module includes a gas flow meter 1, a sewage flow meter 2, a vacuum pressure s...

Embodiment 2

[0087] A control method for a vacuum drainage pumping station, combining Figure 1 to Figure 5 , including the following steps:

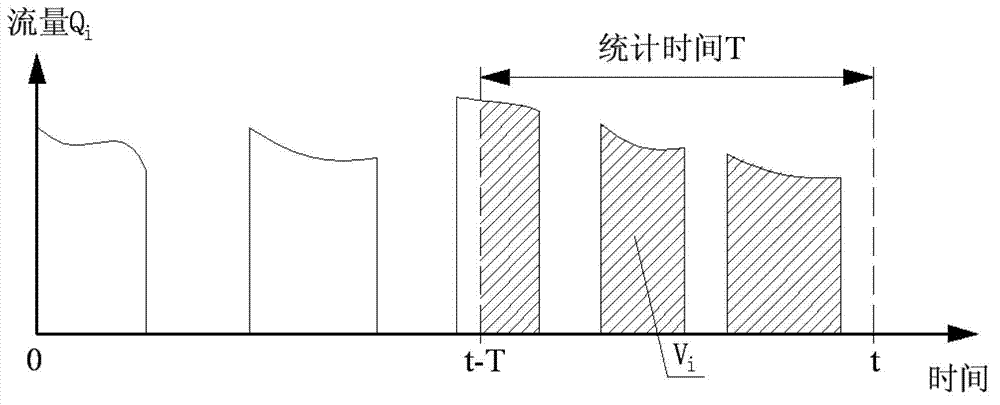

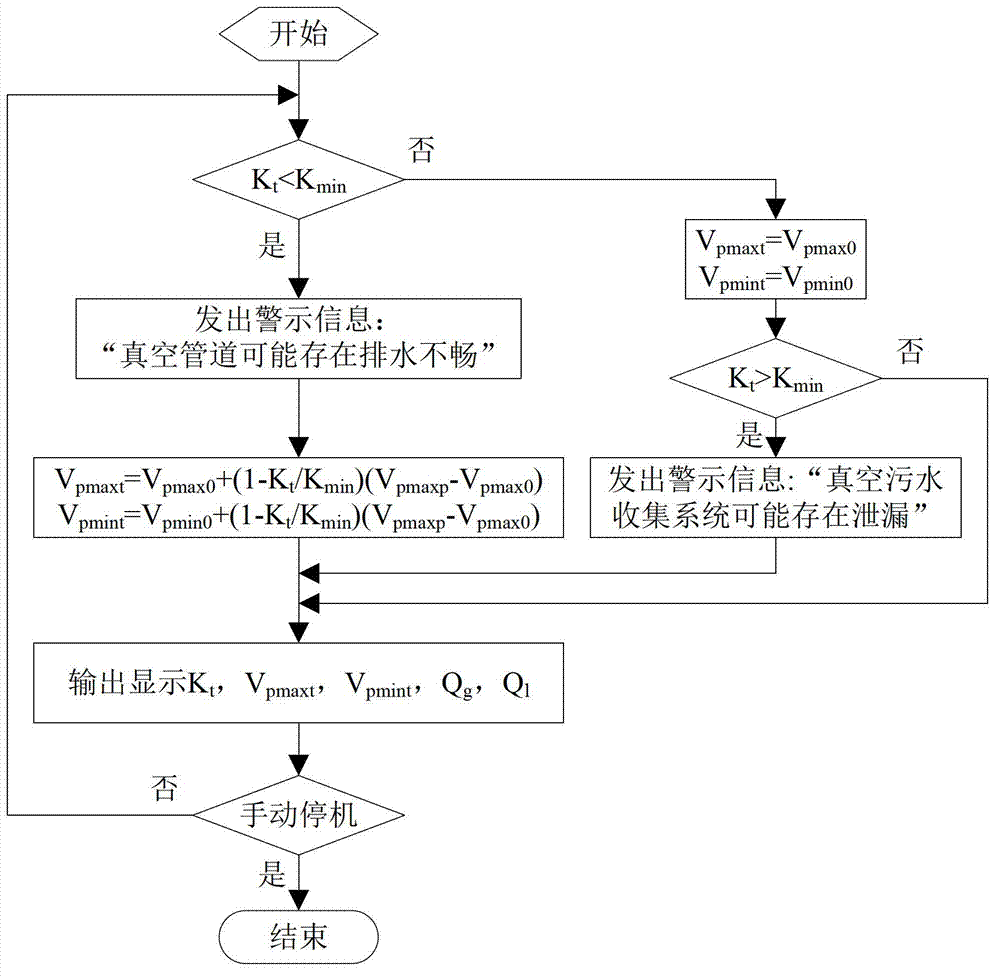

[0088] 1) Use the analysis module 5 to pre-set the initial upper limit V of the working vacuum of the system pmax0 is 60kPa and the initial lower limit V pmin0 is 50kPa; use the gas flow meter 1 and the sewage flow meter 2 to monitor the gas flow Q discharged by the vacuum pump 9 and the sewage pump 10 respectively g and sewage flow Q l ; Utilize the analysis module to count a statistical period T as the gas volume V discharged by the vacuum pump 9 and the sewage pump 10 within 30 minutes g and sewage volume V l , and then calculate the air-water ratio K in this statistical period t . in, i=g or l, K t =V g / V l , t is the current moment, and T is the set statistical period. Such as figure 2 Schematic for the sliding integration method.

[0089] Such as image 3 As shown, the dynamic adjustment of the working vacuum degree is carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com