Binder compositions comprising lignin derivatives

A technology of composition and adhesive, applied in the field of composition of natural lignin derivatives, can solve the problems of reduced method efficiency, loss of resin efficiency, premature polymerization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Preparation of MDI / Lignin

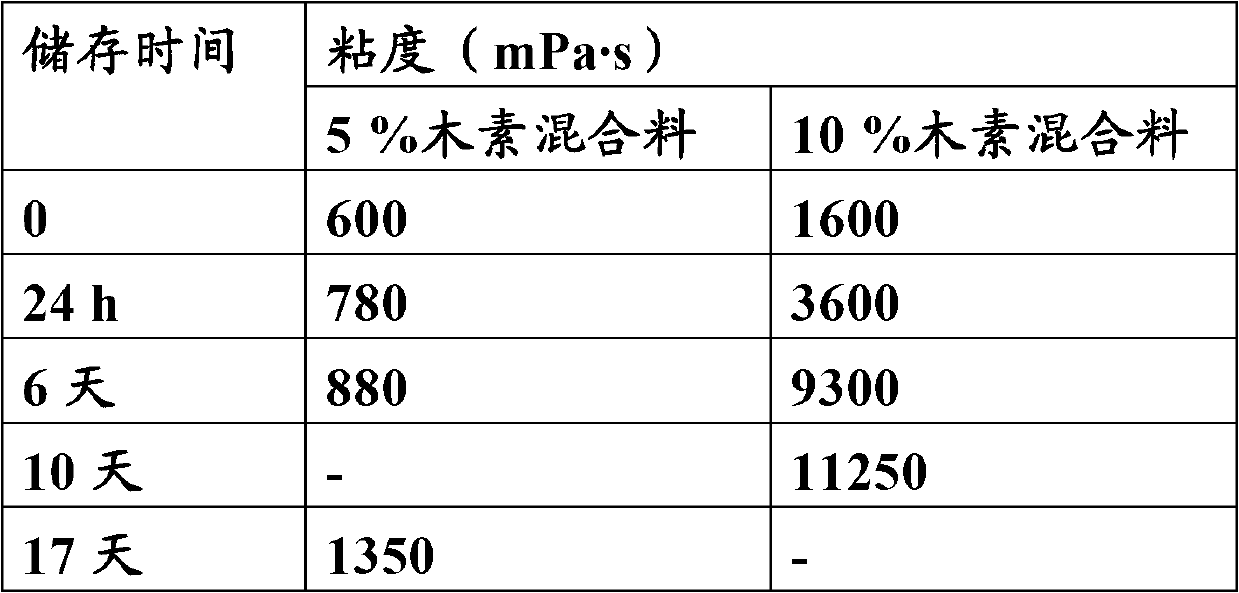

[0085] Two batches of 10 g of powdered lignin derivative were dissolved in two aliquots of 50 g of acetone to form a 20% wt. / wt. solution. Then 100g of MDI (Rubinate 1780) was mixed into one solution and 200g of MDI (Rubinate 1780) into the other. Both solutions were subsequently vacuum distilled at room temperature for 2 hours. This removes 95% of the acetone, which can be stored and reused. Both compositions were stored for several days and their viscosities were determined (Table 1). The results indicated that the mixture was not completely stable but not so unstable that it could not be used.

[0086] Table 1. Viscosity and stability of MDI-lignin resins

[0087]

[0088] In addition, 5 g and 10 g of hardwood lignin powder were directly mixed with 100 g of MDI resin (Rubinate 1780). The suspension appears stable for at least 24 hours, but separation or precipitation occurs after prolonged periods.

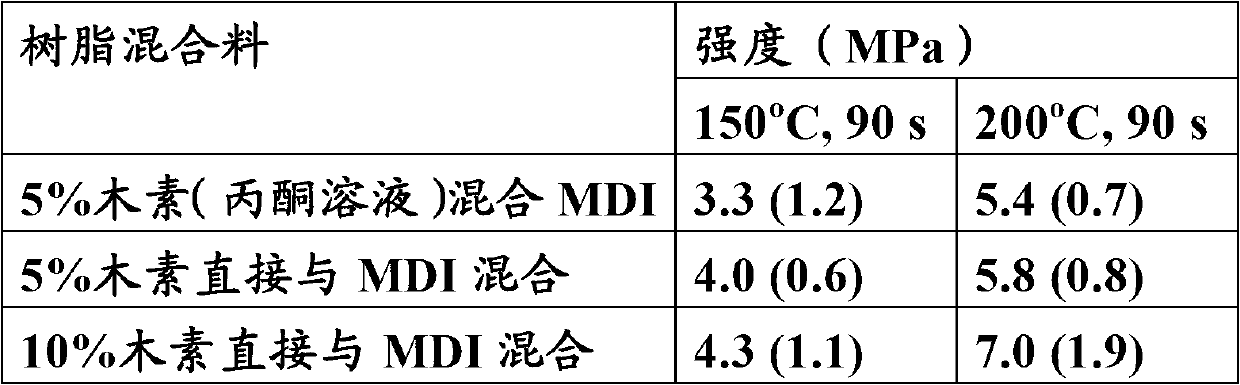

[0089] A sample of a 5% MDI-...

Embodiment 2

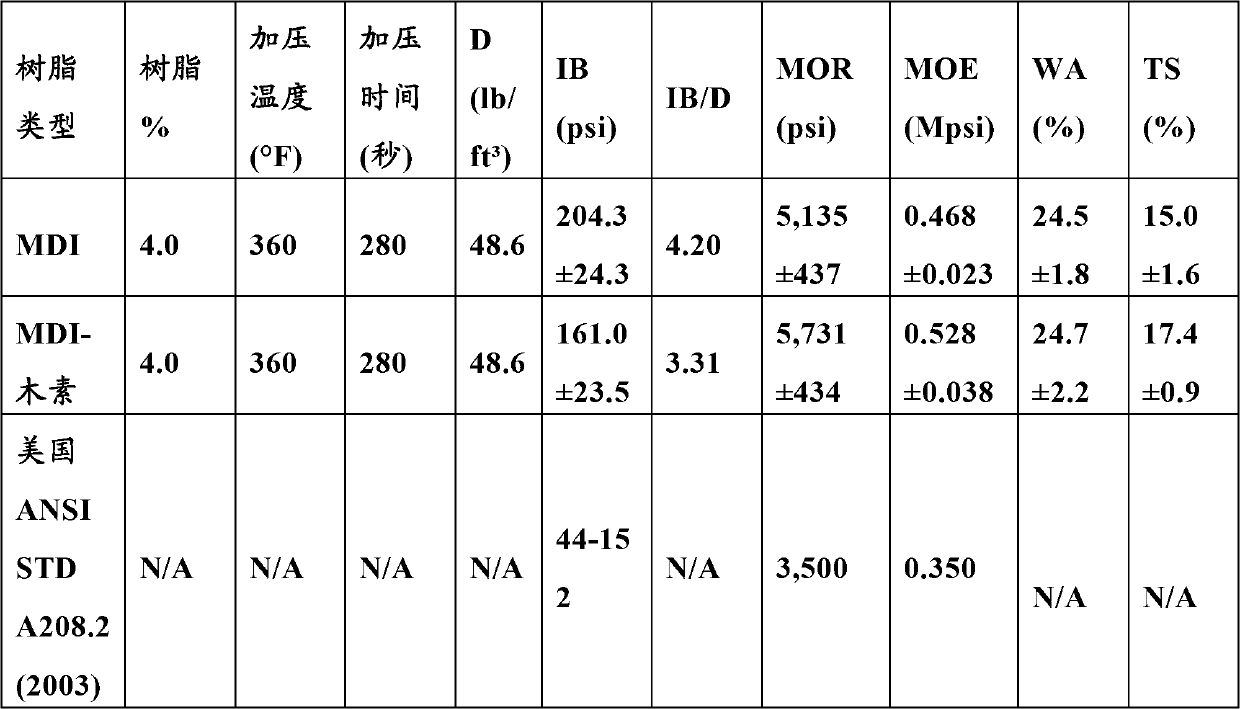

[0108] Conduct further tests to compare lignin-phenolic resin (LPF) and commercially available phenolic resin (PF) as OSB surface layer binder for OSB panel performance and evaluate the replacement of OSB core with 30%, 40% and 50% LPF resin Viability of commercially available pMDI resin in the layer.

[0109] OSB board manufacturing

[0110]

[0111]

[0112] Wood Type: Poplar

[0113] OSB shavings: sieved and dried to 2% moisture content

[0114] Target felt moisture content: 6%-7%

[0115] Surface / core ratio: 50 / 50

[0116] Plate Thickness: 7 / 16”

[0117] Board Dimensions: 4’x8’x7 / 16”

[0118] Target Density: 38lb / ft 3

[0119] Top coat resin: PF or lignin-PF at 3% solid addition rate (heat to 30°C before mixing)

[0120] Core resin: pMDI / lignin-PF (100:0, 70:30x1.5, 60:40x1.5 and 50:50x1.5)

[0121] E-wax: EW58S at 1% solids addition rate (dilute 58% solids to 50% solids with water)

[0122] Pressurization temperature: 215°C

[0123] Pressurization cycle tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com