Precious metal recovery device and recovery method

A precious metal recovery, metal technology, applied in photography technology, instruments, photography auxiliary technology and other directions, can solve problems such as short circuit at the bottom of the container, and achieve the effect of efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

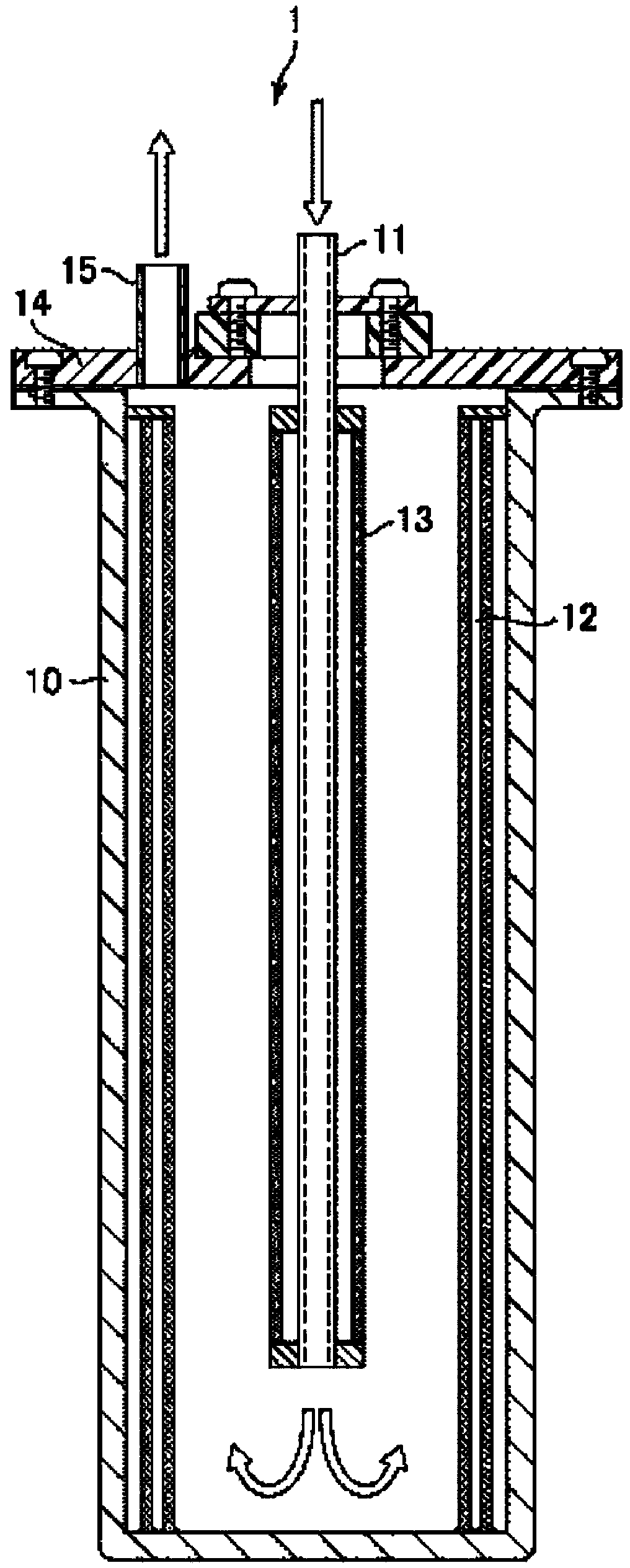

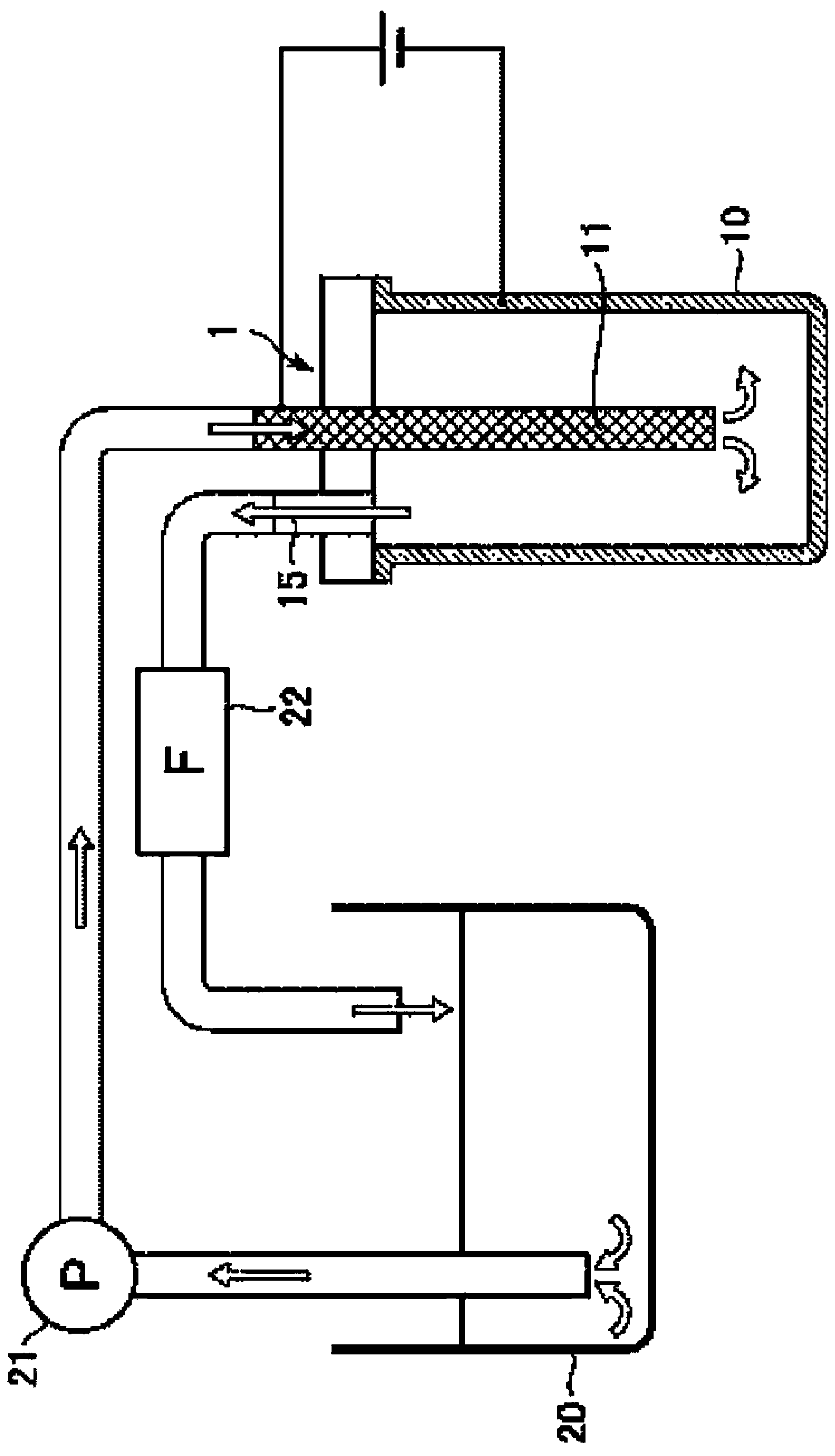

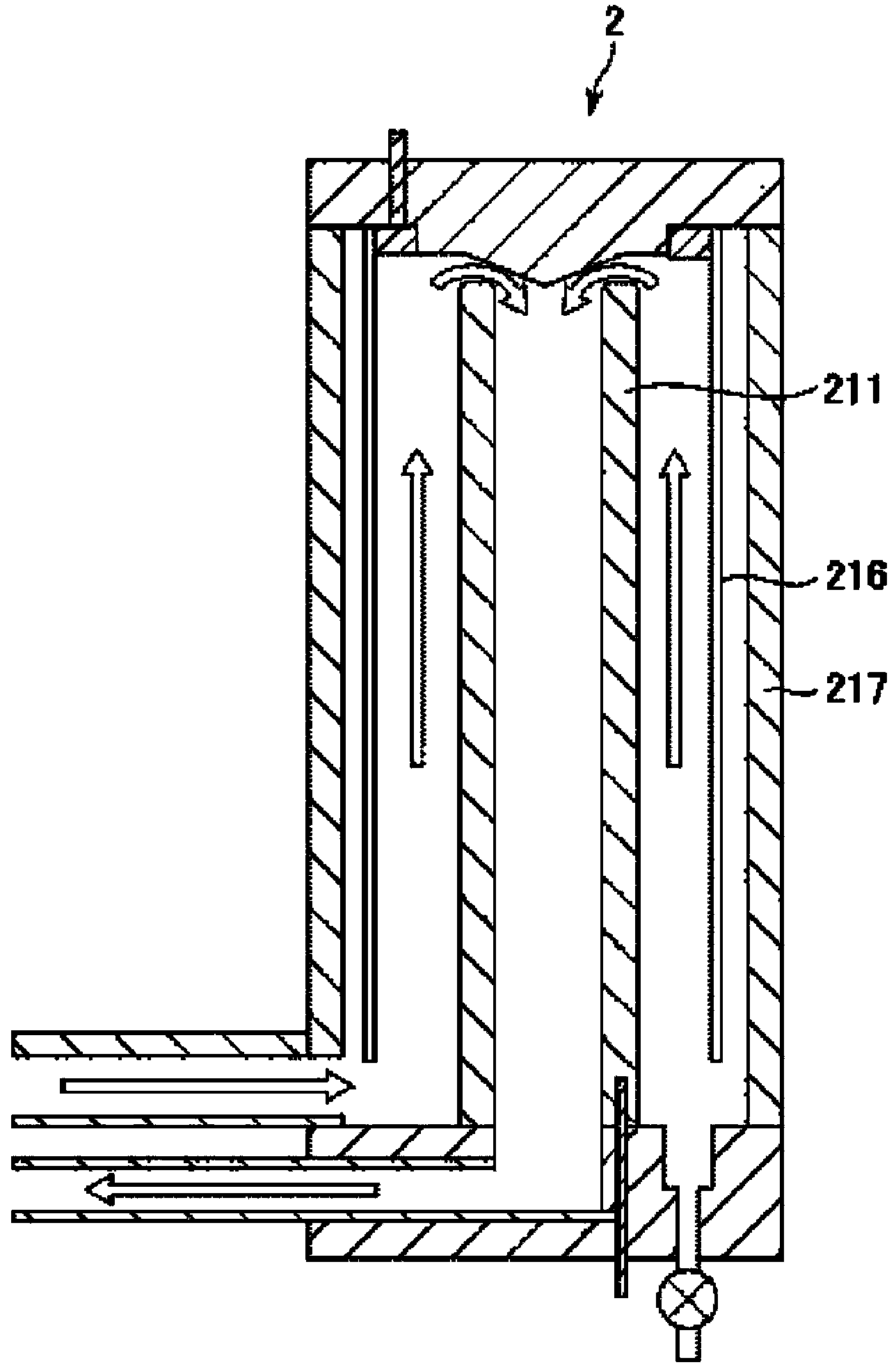

[0046] Below, combine figure 1 and figure 2 , one embodiment of the precious metal recovery apparatus of the present invention will be described. Along the inner circumference of a cylindrical metal container 10 (size: inner diameter 50mm, height 700mm) as an electrolytic cell, the first layer of cylindrical expanded cathode 12 (size: diameter 140mm, plate thickness 1mm, length 685mm, diamond-shaped hole The length of the diagonal line is 6 (major axis) × 3 (short axis) mm), and the second layer of cylindrical expanded cathode 12 is arranged along the inner circumference of the metal container 10 (size: diameter 130mm, plate thickness 1mm, length 685mm , The length of the diagonal of the rhombus hole is 6 (long axis) × 3 (short axis) mm). On the other hand, a tubular anode 11 (dimensions: outer diameter 22 mm, length 690 mm, plate thickness 2 mm) is inserted into the center of the metal container 10, and a cylindrical expanded anode 13 (dimensions: outer diameter 38 mm) is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com