Cylinder head and internal combustion engine equipped therewith

A technology of cylinder head and internal combustion engine, applied in the direction of cylinder head, cylinder, mechanical equipment, etc., can solve the problems affecting the service life of the cylinder head and the wear of the cylinder head, and achieve the effect of improving the service life, reliable wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

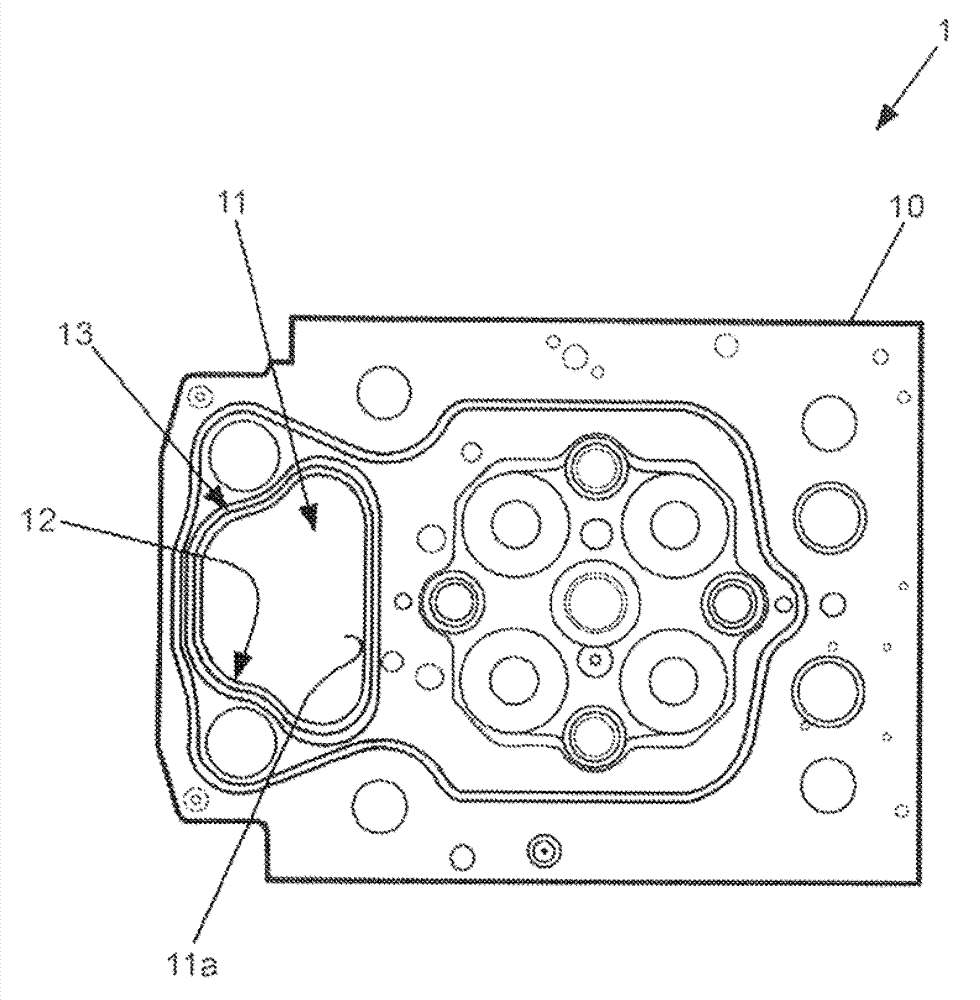

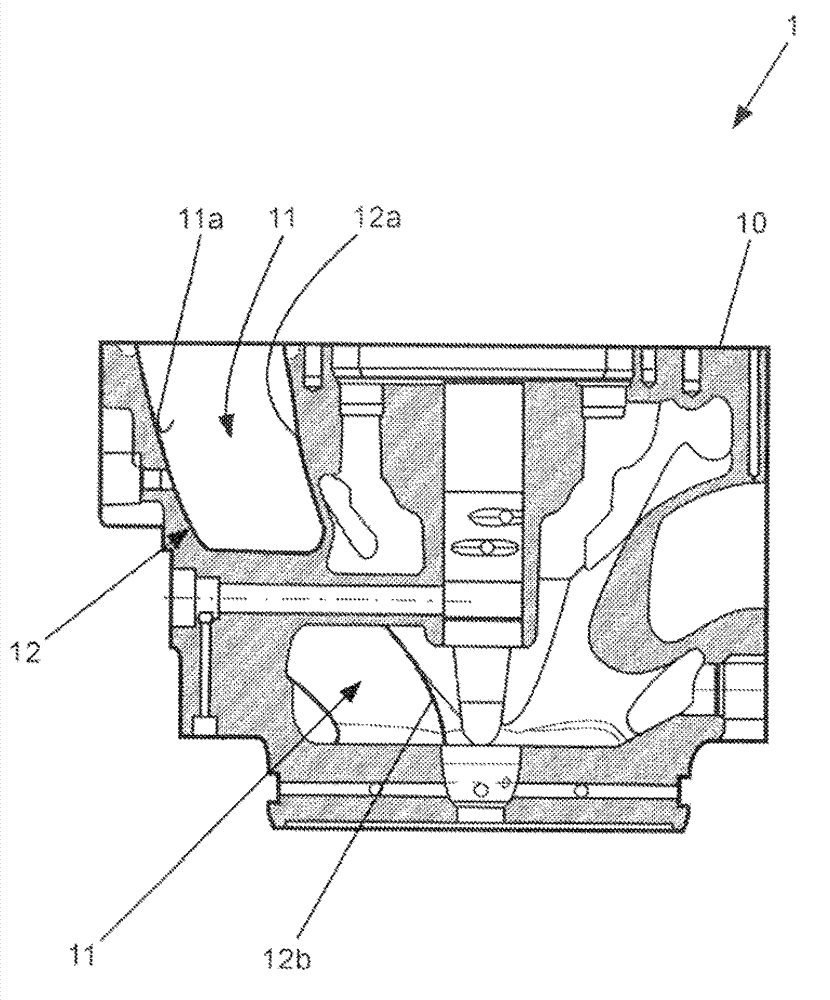

[0027] figure 1 and figure 2 A corresponding illustration of a cylinder head 10 of a turbocharged internal combustion engine 1 (not completely shown) according to an embodiment of the invention is shown. The internal combustion engine 1 is designed as a large diesel engine, such as is used, for example, in marine applications and power station applications (eg power station applications).

[0028] The internal combustion engine 1 is equipped with an exhaust gas recirculation system (not shown) as described here in its basic function, for example in DE 4231 218 C1 or in DE 10 2005 017 905 A1.

[0029] The cylinder head 10 is made of an inexpensive but corrosive casting material, preferably EN-GJS-400-15 (GGG-40).

[0030] The cylinder head 10 of the internal combustion engine 1 has a plurality of medium channels (identified only one medium channel 11 ) each having a medium contact surface provided for conducting the medium.

[0031] According to the invention, the medium co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com