Warm-water fermenting method for boiled bamboo shoots

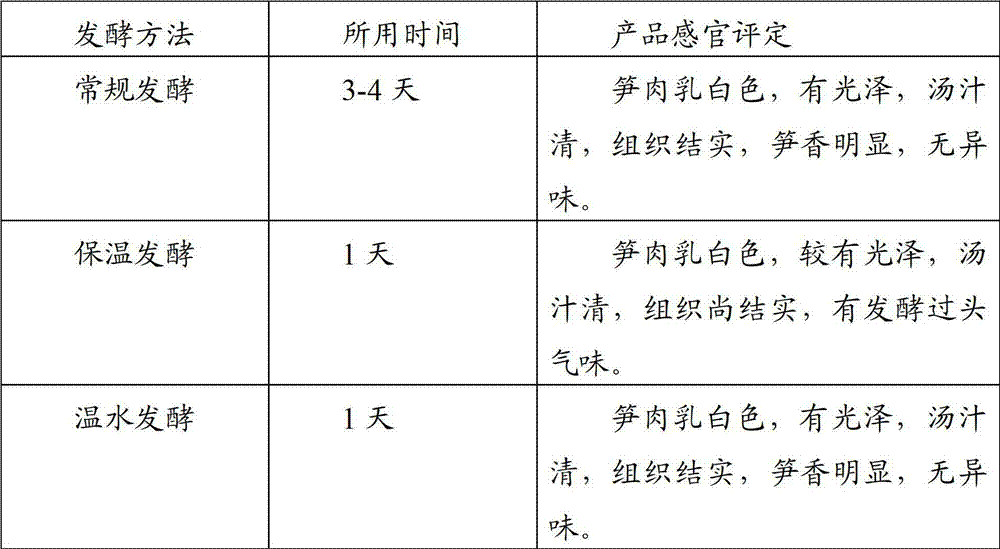

A fermented water and warm water technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of affecting product aroma, taste, color, affecting equipment turnover and site utilization, unstable PH value control, etc., to shorten fermentation time Time, high production efficiency, stable pH effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Optimum example: wash 100 cans of boiled bamboo shoot raw materials, boil them for 70 minutes, change the water and cool for 30 minutes, peel off the shells and pack them into cans, add 11KG of bamboo shoot solids to each can, add 8kg of warm water at 35-37°C to each can, and adjust the pH value of the warm water 6.8, the PH value of the raw material is above 7. After 12 hours of lactic acid bacteria fermentation, test the pH value, the pH value of the water is 4.2, the pH value of the raw material is 4.6, change the water and add warm water at 35-37°C, test the pH value after 12 hours, the pH value of the water is 4.0, and the pH value of the raw material If the value is 4.2, change to normal temperature water for sterilization, the sterilization temperature is 95-97°C, the sterilization time is 120 minutes, and natural cooling, the pH value of the finished product is around 4.4. The obtained boiled bamboo shoots are milky white, shiny, with clear soup, firm texture, o...

Embodiment 2

[0028] Wash 100 cans of boiled bamboo shoot raw materials, boil them for 80 minutes, change the water and cool for 25 minutes, peel off the shells and put them in cans, add 11KG of bamboo shoot solids to each can, add 8kg of warm water at 35-37°C to each can, the pH of the warm water is 6.8, and the pH of the raw materials Value 7 or more. After 12 hours of lactic acid bacteria fermentation, test the pH value, the pH value of the water is 4.2, the pH value of the raw material is 4.6, change the water and add warm water at 35-37°C, test the pH value after 12 hours, the pH value of the water is 4.0, and the pH value of the raw material If the value is 4.2, change to normal temperature water for sterilization, the sterilization temperature is 95-97°C, the sterilization time is 110 minutes, and natural cooling, the pH value of the finished product is between 4.3-4.6. The obtained boiled bamboo shoots are milky white, shiny, with clear soup, firm texture, obvious bamboo shoot fragr...

Embodiment 3

[0030] Wash 100 cans of boiled bamboo shoot raw materials, boil them for 80 minutes, change the water and cool for 35 minutes, peel off the shells and put them in cans, add 11KG of bamboo shoot solids to each can, add 8kg of warm water at 35-37°C to each can, the pH of the warm water is 6.8, and the pH of the raw materials Value 7 or more. After 11 hours of lactic acid bacteria fermentation, test the pH value, the pH value of the water is 4.2, the pH value of the raw material is 4.6, change the water and add warm water at 35-37°C, test the pH value after 11 hours, the pH value of the water is 4.0, and the pH value of the raw material If the value is 4.2, change to normal temperature water for sterilization, the sterilization temperature is 95-97°C, the sterilization time is 120 minutes, and natural cooling, the pH value of the finished product is between 4.3-4.6. The obtained boiled bamboo shoots are milky white, shiny, with clear soup, firm texture, obvious bamboo shoot fragr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com