LED substrate removal method and LED chip prepared thereby

A technology of LED chips and substrates, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult to meet demand for finished product quality, limited luminous efficiency, harshness, etc., and achieve the effect of reducing cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

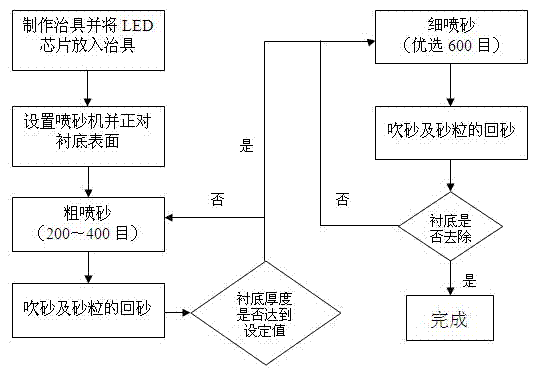

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings. figure 1 A kind of embodiment that it adopts is represented schematically.

[0019] A method for removing an LED substrate according to the present invention comprises the following steps:

[0020] S1. Make a jig and put the LED chip into the fixed position of the jig;

[0021] S2. Set up the sandblasting machine, and move the nozzle of the sandblasting machine to face the surface of the LED substrate that needs to be removed;

[0022] S3. Select sand with a mesh number of 200-400 for rough sandblasting;

[0023] S4. Perform sand blowing and sand return on the surface of the LED substrate after rough sand blasting;

[0024] S5. Select sand with a mesh number of 500-650 for fine sandblasting;

[0025] S6. Carry out sand blasting and sand return of sand grains on the surface of the LED substrate after fine sand blasting;

[0026] S7. Determine whether the LE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com