Infrared array heating system

A technology of infrared lamp array and heating system, which is applied in space navigation equipment, simulation device of space navigation conditions, transportation and packaging, etc., can solve the problems of vacuum thermal test of spacecraft components, etc. Reliability, the effect of avoiding thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

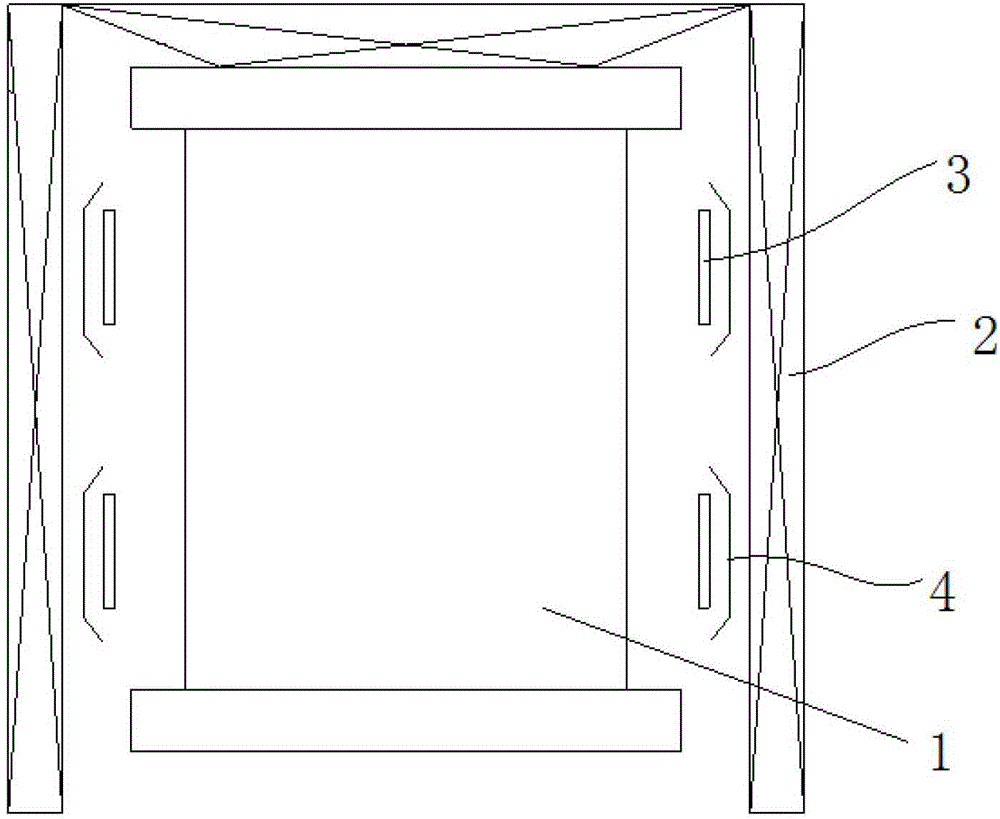

[0022] See attached figure 1 , when testing some special products of the aerospace system, the test product 1 is fixed by the tooling 2, and the tooling 2 can be different according to the shape of the test product 1, and the infrared lamp array 3 is set outside the test product 1, and the infrared lamp The array 3 is arranged according to the shape of the test product 1, so that it is evenly arranged outside the surface of the test product. The infrared lamp array 3 is fixed by the upper support set on the tooling 2. The surface of the test product 1 was uniformly heated. The number and distribution density of infrared lamps in the infrared lamp array 3 are set according to the heating demand of the test product 1, which can provide more than 1500W / m 2 Heat flux density, up to 1700W / m 2 .

[0023] Continue to see attached figure 1 , the shape of the tooling 2 is set to surround the test product 1, and the infrared light array 3 is set between the tooling 2 and the test pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com