Combined type chain wheel head wheel set

A combined, sprocket technology, applied in the field of the head wheel set, can solve the problems of dismantling the bearing, large additional workload and loss of the scraper conveyor, and achieves the effects of low maintenance cost, reduced material consumption, and convenient assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

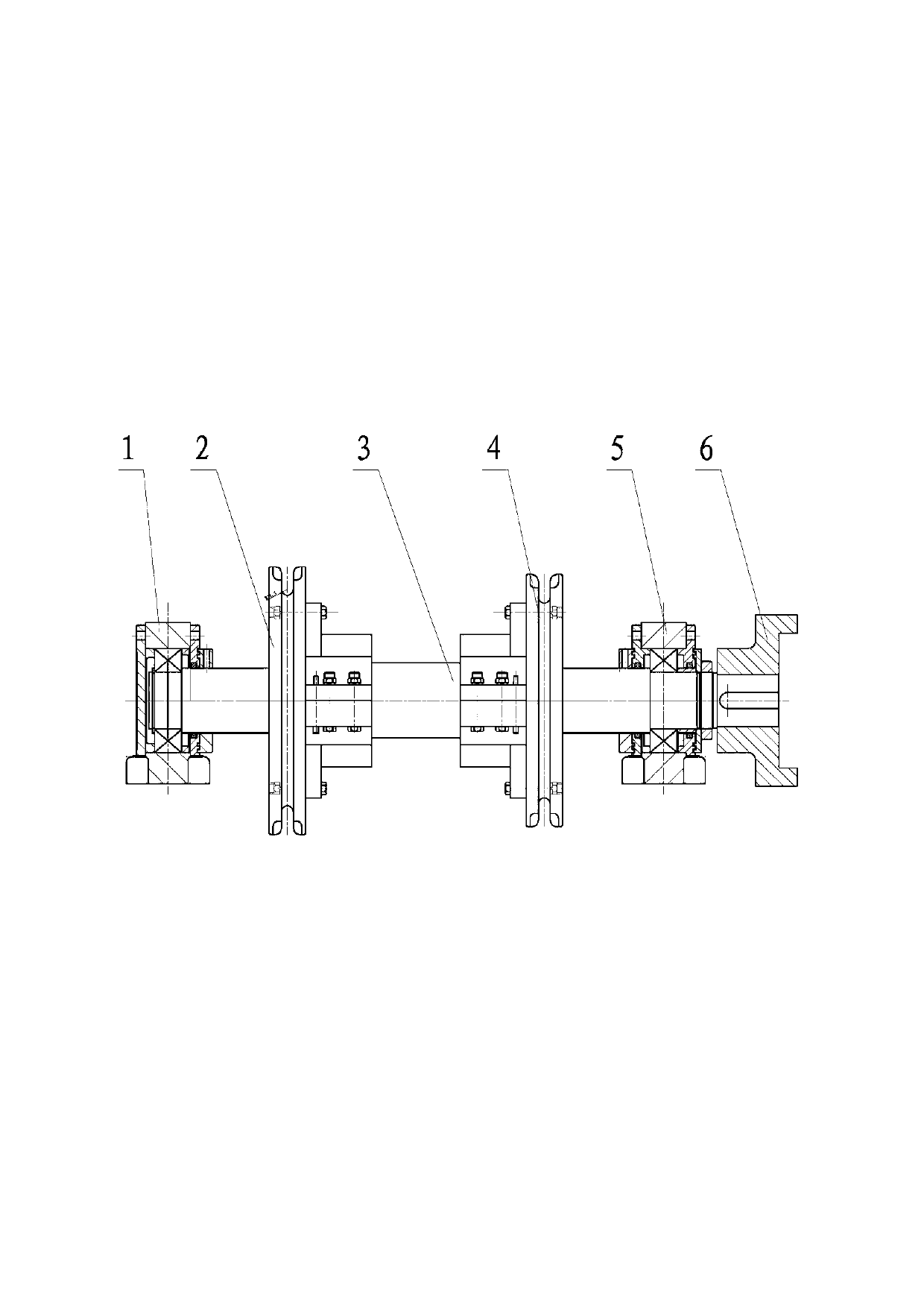

[0013] like figure 1 Shown, the present invention is made up of left bearing block 1, left sprocket wheel 2, main shaft 3, right sprocket wheel 4, right bearing seat 5, half coupling 6 etc. The left bearing seat 1, the main shaft 3, the right bearing seat 5, and the half-coupling 6 form a drive shaft system, and the half-coupling 6 transmits an external driving force to drive the main shaft 3 to rotate.

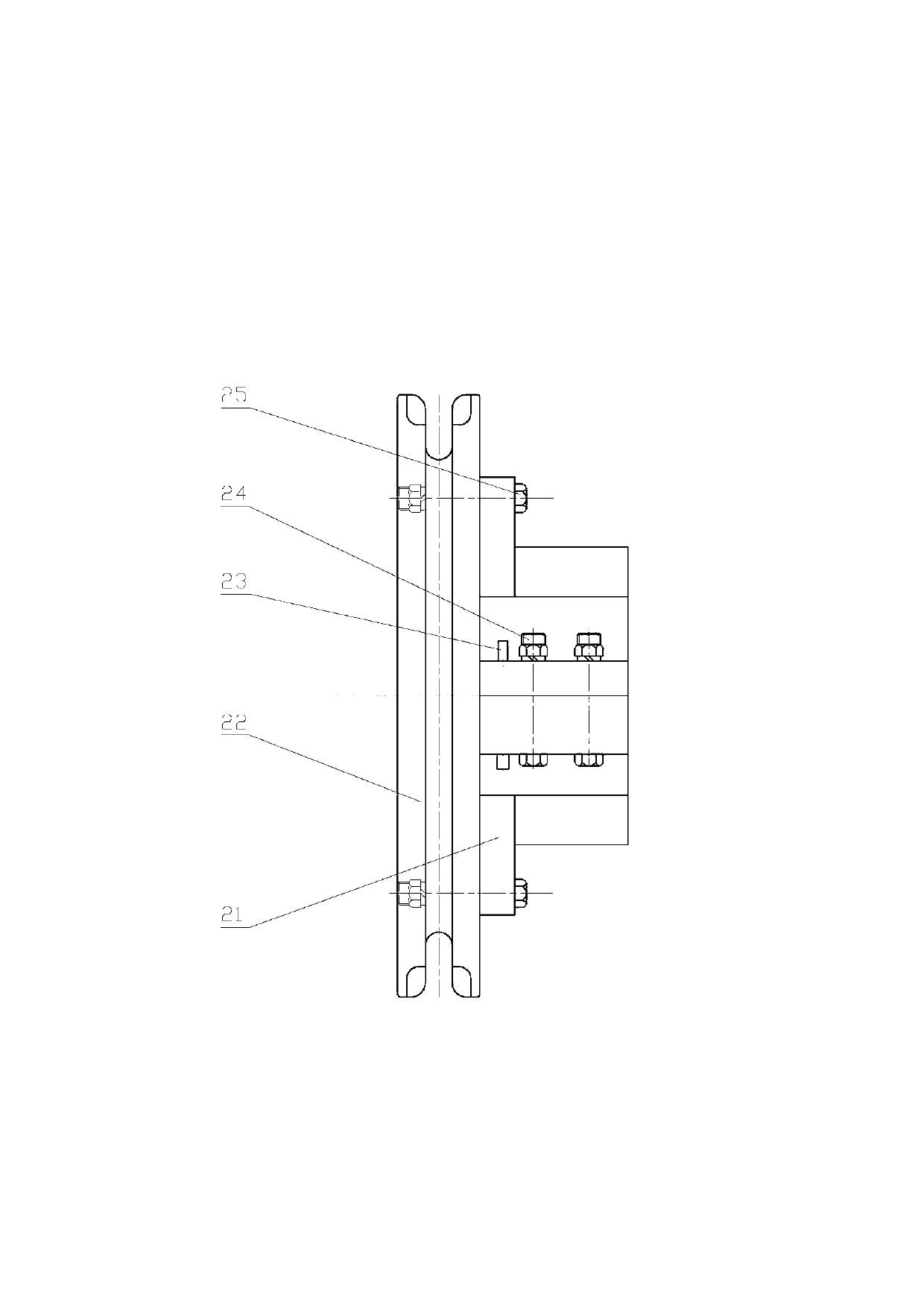

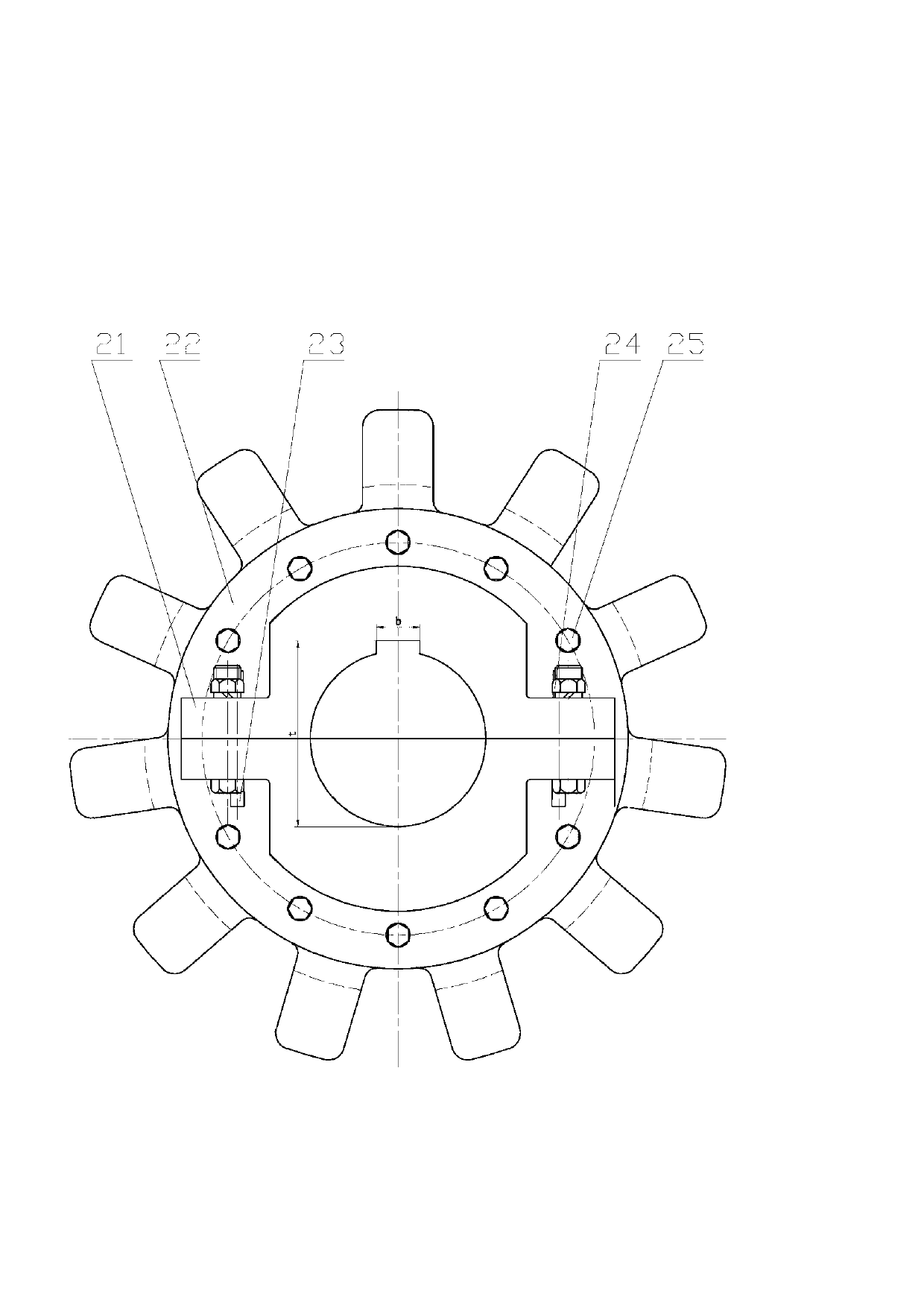

[0014] like figure 2 , 3 Shown, left chain wheel 2 and right chain wheel 4 have wheel hub 21, belt gear hub 22, alignment pin 23, wheel hub connection bolt 24, wheel hub and belt gear edge connection bolt 25 and form. Both the hub 21 and the gear rim 22 are split structures, and the half gear rim 22 is fastened on the hub 21 with connecting bolts 25 between the hub and the gear rim. The hub 21 is divided into two halves along the centerline, and the half hub 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com