Road asphalt mixture rut resisting additive and preparation method thereof

An anti-rutting additive and road asphalt technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problem of few mature products, achieve the effects of improving anti-rutting performance, reducing costs, and optimizing experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

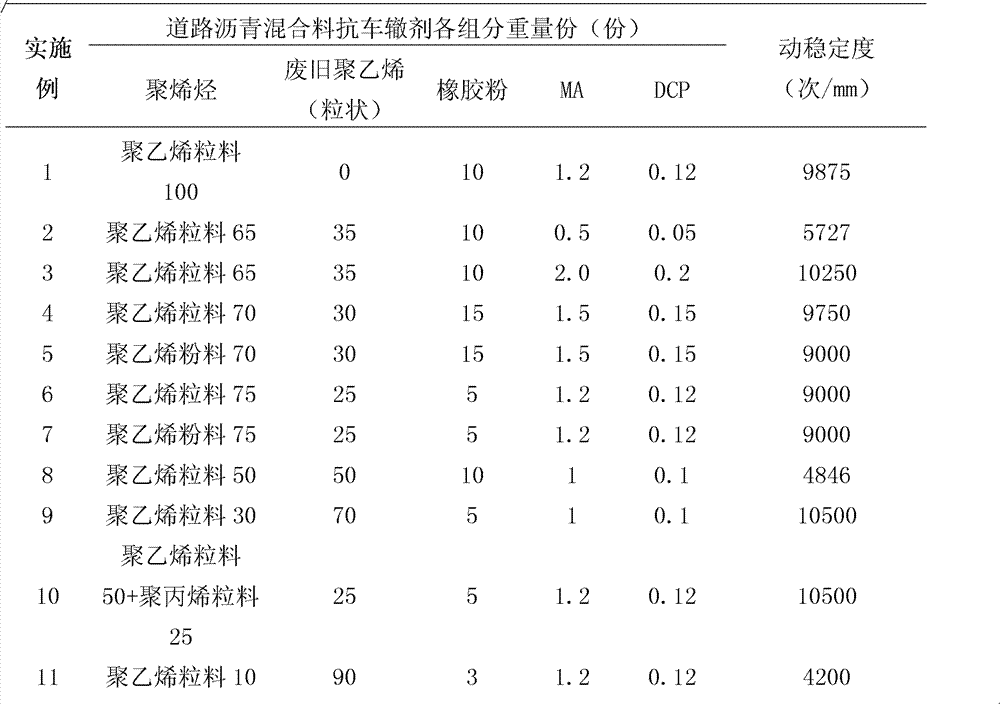

Examples

Embodiment 1

[0020] An anti-rutting additive for road asphalt mixture, which is prepared by mixing the following raw materials, melt extruding, pelletizing, and drying. The composition of the raw materials and the weight of each raw material are:

[0021] New polyethylene (granular) 100kg,

[0022] Waste rubber powder 10kg,

[0023] Maleic anhydride 1.2kg,

[0024] Dicumyl peroxide 0.12kg.

[0025] The preparation method is as follows: according to the above ratio, polyethylene, waste rubber powder, maleic anhydride, and dicumyl peroxide are evenly mixed at room temperature, and the mixture is added to a twin-screw extruder. Body temperature, 30-50 rpm host speed, 30-60 rpm feeding rate, melt extrusion, pelletizing, drying (drying at room temperature for 5-15min), to obtain 2-5mm long road asphalt mixture Anti-rutting additive (product of the present invention).

[0026] Polyethylene, waste rubber powder, maleic anhydride, and dicumyl peroxide are all existing raw materials.

[0027] ...

Embodiment 2

[0029] An anti-rutting additive for road asphalt mixture, which is prepared by mixing the following raw materials through melt extrusion, pelletizing, and drying. The composition of the raw materials and the weight of each raw material are:

[0030] Low-density polyethylene (granular) 65kg,

[0031] Waste low-density polyethylene (granular) 35kg,

[0032] Waste rubber powder 10kg,

[0033] Maleic anhydride 0.5kg,

[0034] Dicumyl peroxide 0.05kg.

[0035]The preparation method is as follows: uniformly mix polyethylene, waste polyethylene, waste rubber powder, maleic anhydride, and dicumyl peroxide at room temperature according to the above ratio, and add the mixture to a twin-screw extruder, ~210°C cylinder temperature, 30~50 rpm host speed, 30~60 rpm feeding rate, melt extrusion, pelletizing, drying (blow drying at room temperature for 5-15min), to obtain 2~5mm long Product of the present invention.

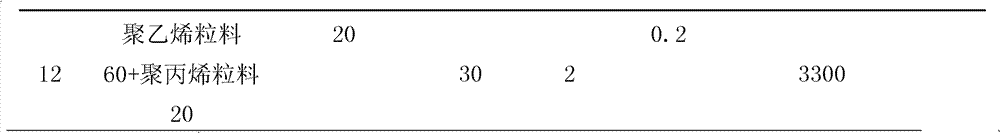

Embodiment 3

[0037] An anti-rutting additive for road asphalt mixture, which is prepared by mixing the following raw materials, melt extruding, pelletizing, and drying. The composition of the raw materials and the weight of each raw material are:

[0038] Low-density polyethylene (granular) 65kg,

[0039] Waste low-density polyethylene (granular) 35kg,

[0040] Waste rubber powder 10kg,

[0041] Maleic anhydride 2.0kg,

[0042] Dicumyl peroxide 0.2kg.

[0043] The preparation method is as follows: uniformly mix polyethylene, waste polyethylene, waste rubber powder, maleic anhydride, and dicumyl peroxide at room temperature according to the above ratio, and add the mixture to a twin-screw extruder, ~210°C cylinder temperature, 30~50 rpm host speed, 30~60 rpm feeding rate, melt extrusion, pelletizing, drying (blow drying at room temperature for 5-15min), to obtain 2~5mm long Product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com