Nitrogen oxide red fluorescent powder and preparation method thereof

A technology of red phosphors and nitrogen oxides, applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve problems such as excellent color rendering index, lack of red light, etc., and achieve wide process window, The effect of simple operation and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Follow Y 5.97 Si 3 N 4 o 9 :0.06Sm 3+ Stoichiometric ratio weighs Y 2 o 3 、Si 3 N 4 、Sm 2 o 3 , and 5wt% flux (i.e. catalyst) NaF is placed in a mortar and thoroughly ground and mixed evenly, then placed in a graphite crucible, the crucible is placed in a carbon tube vacuum furnace, under protective gas N / H=3:1 ( (volume ratio) at a rate of 10°C / min to 1550°C, then keep warm for 12 hours, then cool down to room temperature naturally, take out, grind and sieve to obtain a powder with a particle size parameter D50=8 microns, and then wash with 10% dilute hydrochloric acid, And after drying at 80°C for 2 hours, the red phosphor Y was obtained 5.97 Si 3 N 4 o 9 :0.06Sm 3+ .

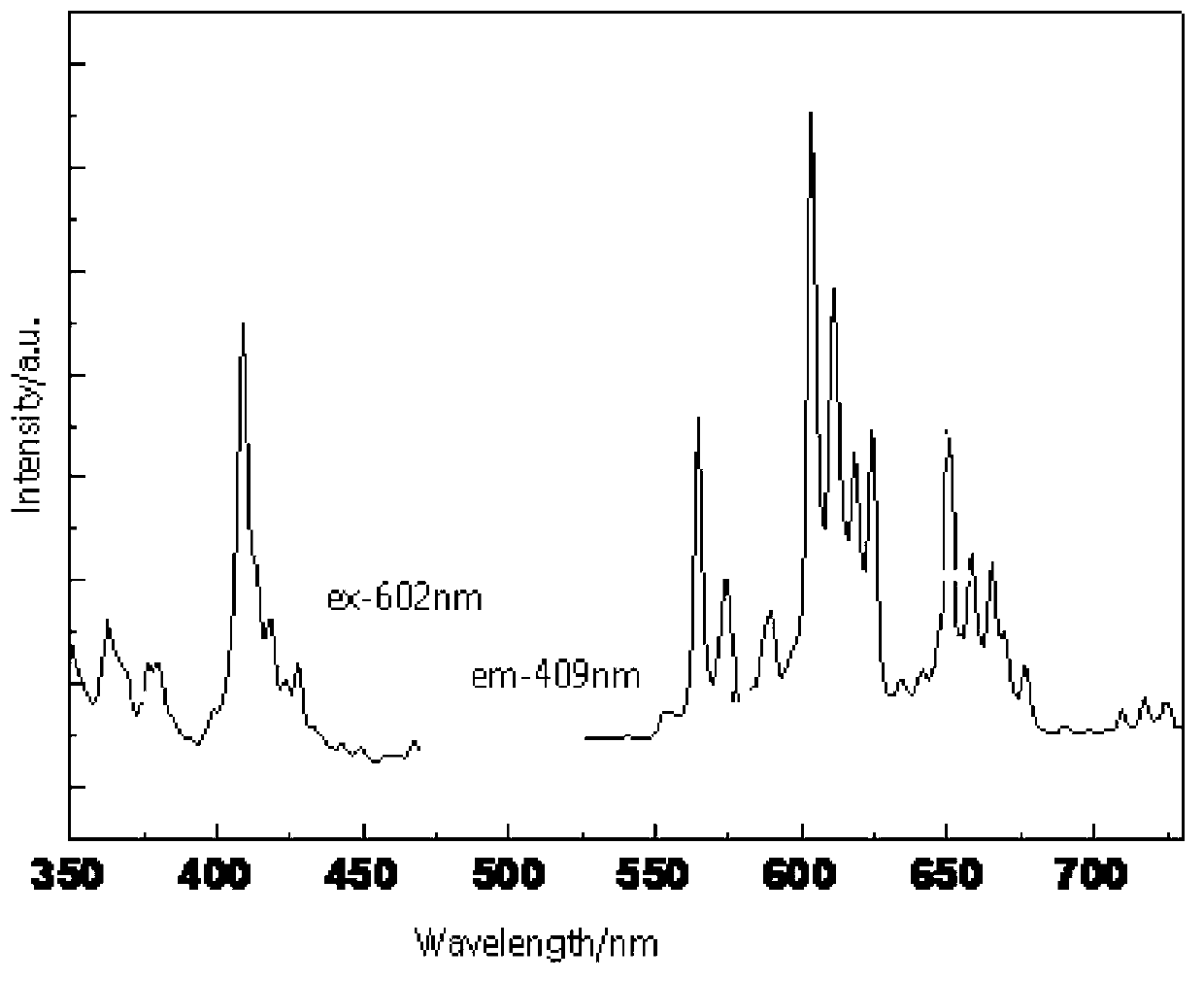

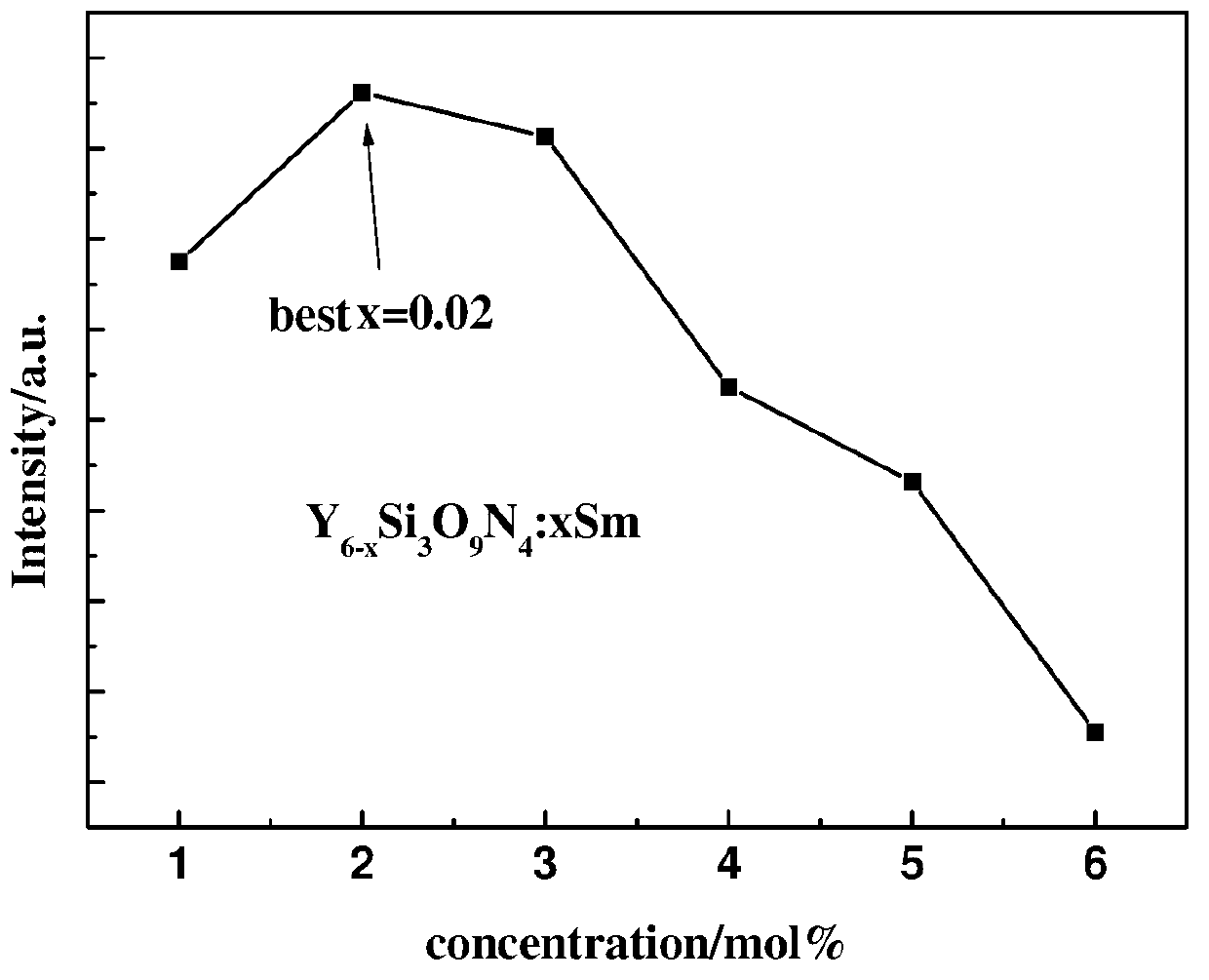

[0021] Such as figure 1 , for Y 5.97 Si 3 N 4 o 9 :0.06Sm 3+ The emission spectrum and excitation spectrum of the figure; the figure shows that the sample Y is irradiated with 404nm excitation light 5.94 Si 3 N 4 o 9 :0.06Sm 3+ , to obtain the emission spectrum of the fluoresc...

Embodiment 2

[0024] According to YTb 4.9 Si 3 N 4 o 9 :0.1Sm 3+ Stoichiometric ratio weighs Y 2 o 3 , Tb 4 o 7 、Si 3 N 4 、Sm 2 o 3 , and 3wt% flux (i.e. catalyst) NaF is placed in a mortar and thoroughly ground and mixed evenly, then placed in a graphite crucible, the crucible is placed in a carbon tube vacuum furnace, under protective gas N / H=9: 1 ( volume ratio) at a rate of 15°C / min to 1700°C, after 14 hours of heat preservation, it was naturally cooled to room temperature, taken out, ground and sieved to obtain a powder with a particle size parameter D50=12 microns, then washed with 5% dilute hydrochloric acid and dried at 60 After drying at ℃ for 5 hours, the red phosphor YTb can be obtained 4.9 Si 3 N 4 o 9 :0.1Sm 3+ .

Embodiment 3

[0026] According to TbGd 4.99 Si 3 N 4 o 9 :0.01Sm 3+ Stoichiometric ratio weighs Tb 4 o 7 、Gd 2 o 3 、Si 3 N 4 、Sm 2 o 3 , and 1wt% flux (i.e. catalyst) H 3 BO 3 Put it in a mortar, grind and mix well, then put it in a graphite crucible, place the crucible in a carbon tube vacuum furnace, and raise the temperature at a rate of 5°C / min in a protective gas N / H=97:3 (volume ratio) to 1650°C, keep warm for 10 hours, then cool naturally to room temperature, take out, grind and sieve to obtain a powder with a particle size parameter D50=10 microns, then wash with 20% dilute hydrochloric acid and dry at 90°C for 3 hours to obtain the red phosphor TbGd 4.99 Si 3 N 4 o 9 :0.01Sm 3+ .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap