Brake caliper assembly of electronic parking brake system for vehicle

A technology of electronic parking brake and brake caliper, applied in the direction of brake type, brake actuator, axial brake, etc., can solve the problem of poor product assembly process, unfavorable axial space layout, high R&D and manufacturing cost, etc. problem, to achieve the effect of reducing the surface friction torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

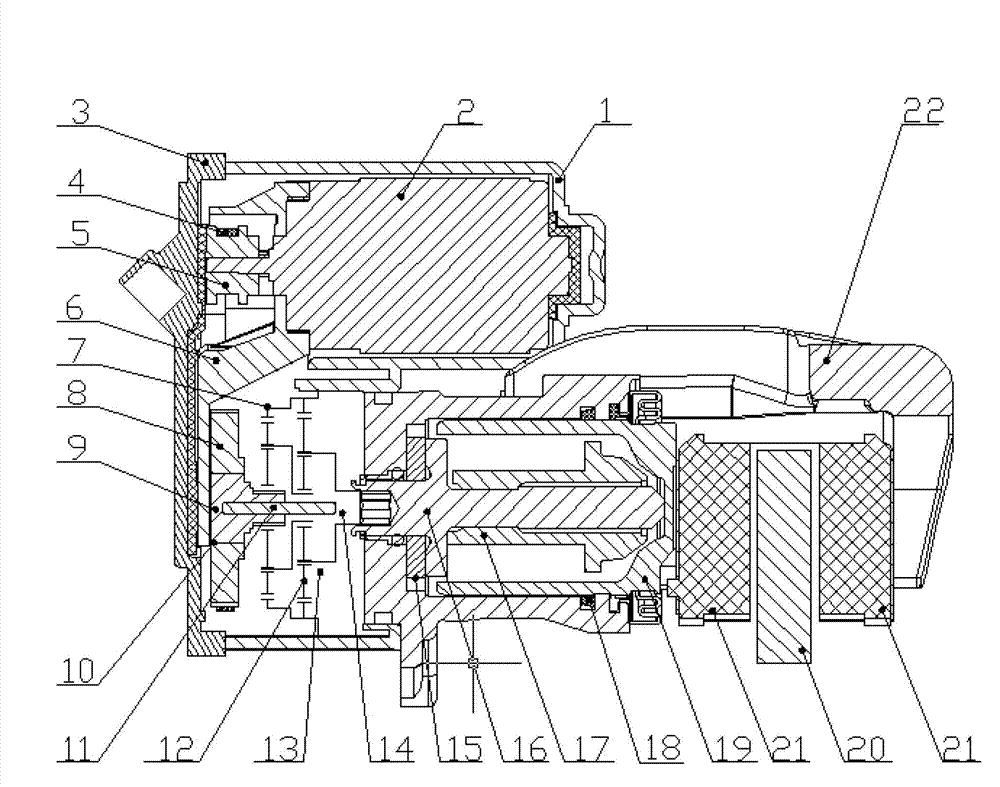

[0026] Such as figure 1As shown, the technical solution provided by the present invention is a brake caliper assembly of an electronic parking brake system for a vehicle, including an actuator assembly and a parking brake caliper, and the actuator assembly is arranged on the The head of the parking brake caliper, the executive mechanism assembly and the parking brake caliper are connected to each other through screws, and the parking brake caliper includes a brake caliper body 22, a parking screw sleeve 17, a parking screw 16, piston 19 and friction plates 21, the brake disc 20 is arranged between the friction plates 21, the parking screw 16 cooperates with the parking screw sleeve 17, and the parking screw 16 The end is equipped with a thin sheet-shaped anti-friction device that acts as an end bearing to reduce the frictional moment of the contact surface. The anti-friction device is a anti-friction sheet 15 , and the anti-friction sheet 15 is in contact with the parking scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com