P-type one-time programmable (OTP) device and manufacturing method thereof

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of low reading current, large chip area, and small current value, so as to improve the conduction current, The effect of improved programming performance and increased coupling capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

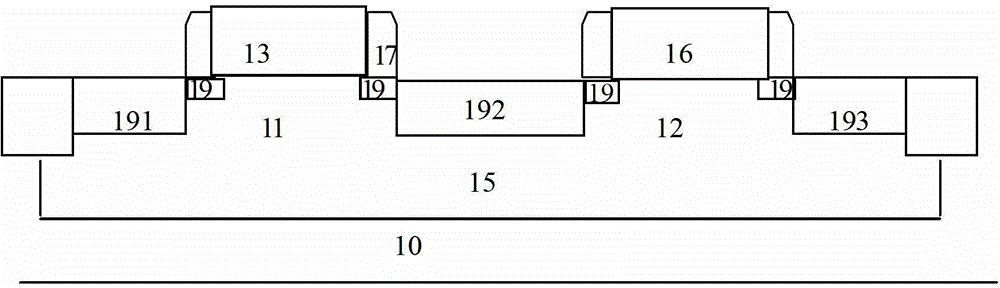

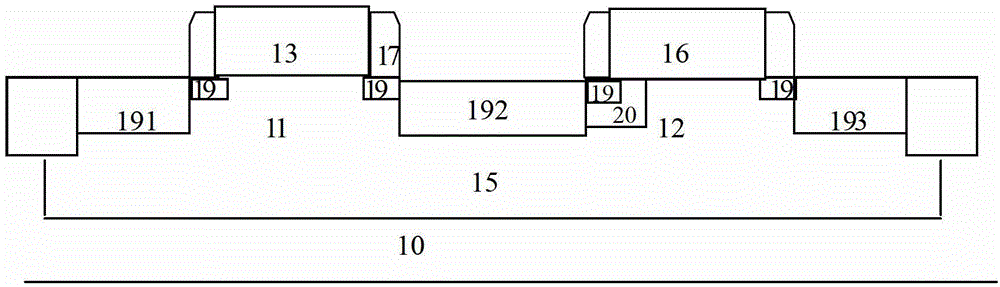

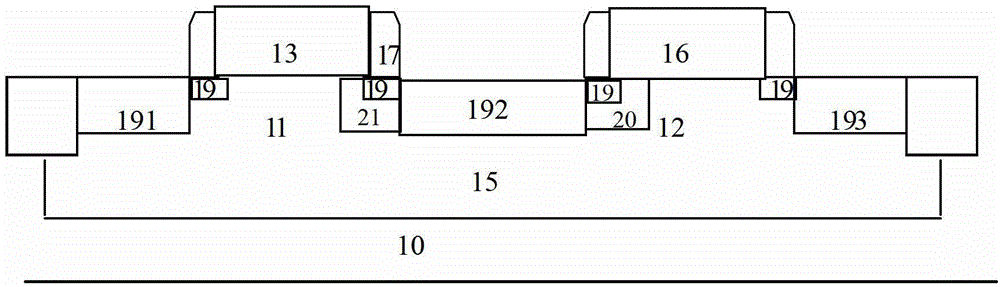

[0036] Such as figure 2 As shown, it is a schematic diagram of the structure of a P-type OTP device according to an embodiment of the present invention. An N-type well 15 is formed on a silicon substrate 10, and a one-time programmable device formed by connecting two PMOS transistors 11 and 12 in series. The first PMOS The transistor 11 is used as a pass transistor of the OTP device, and the second PMOS transistor 12 is used as a storage unit of the OTP device.

[0037] The source of the first PMOS transistor 11 includes a P-type diffusion region 191 and a P-type lightly doped region 19 formed in the N well, and the drain of the first PMOS transistor 11 includes a P-type diffused region 191 formed in the N well. A P-type diffusion region 192 and a P-type lightly doped region 19, the gate 17 of the first PMOS transistor is used as the word line of the OTP device, and the source of the first PMOS transistor 11 is used as the word line of the OTP device. Source of the OTP devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com