High-temperature superconducting motor

A high-temperature superconductivity and wire technology, applied in the field of superconductivity, can solve the problems of occupied space, motor structure, performance and efficiency, and achieve the effect of reducing loss, providing safety and stability, and high-efficiency power output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

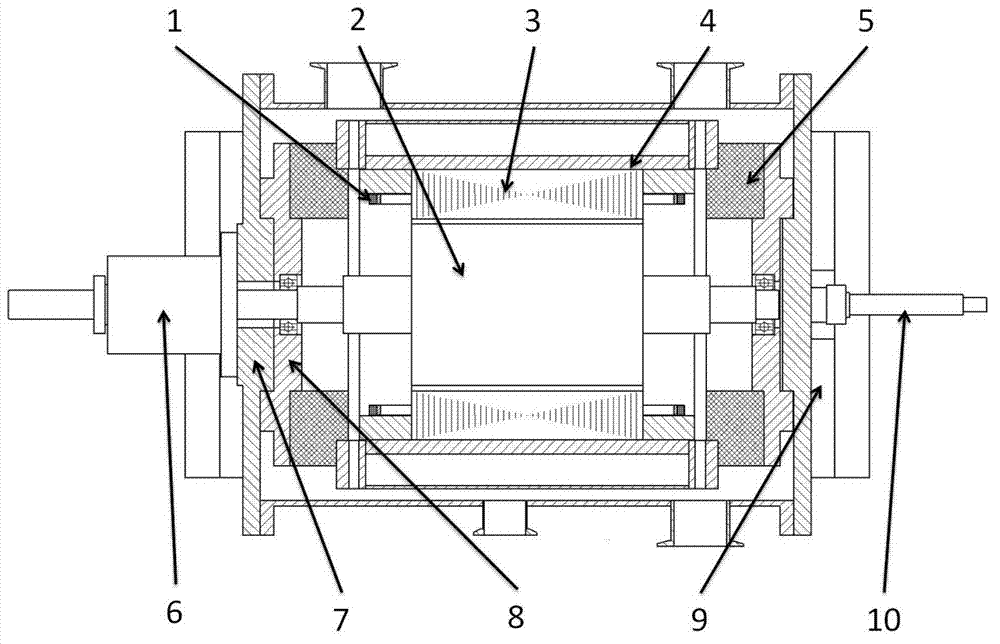

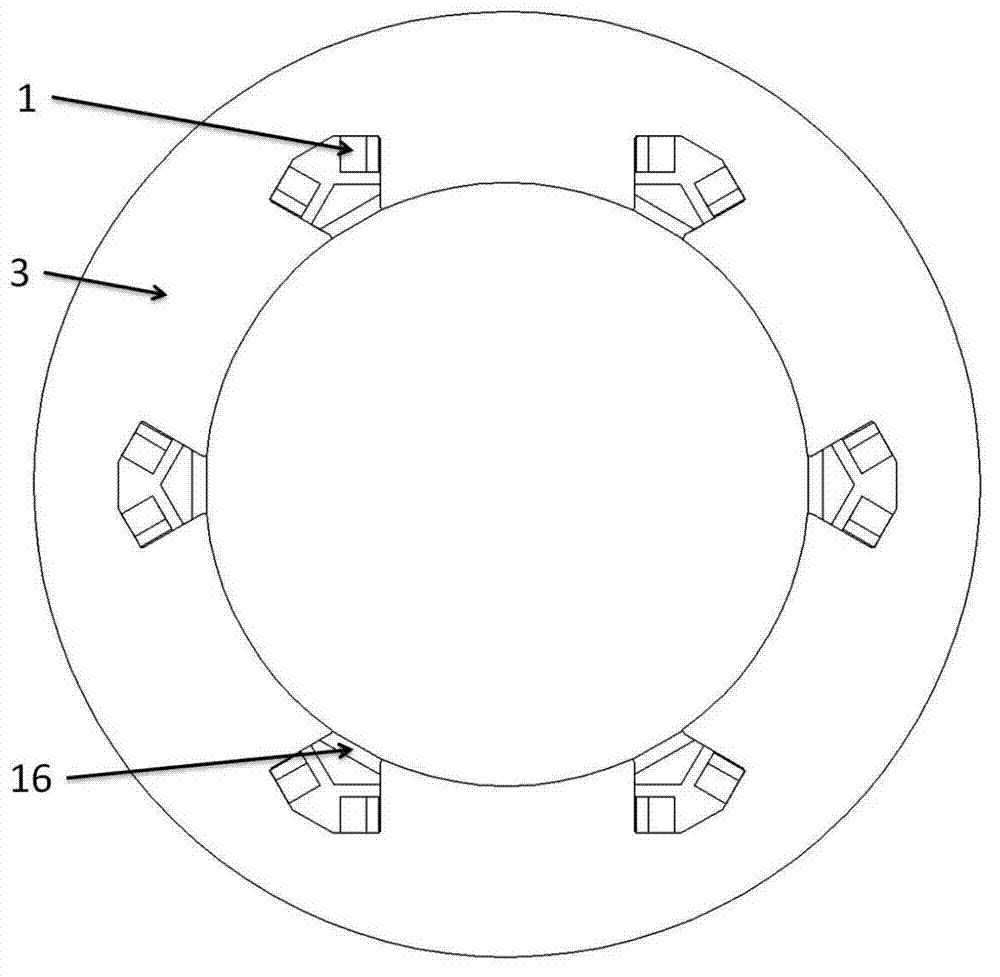

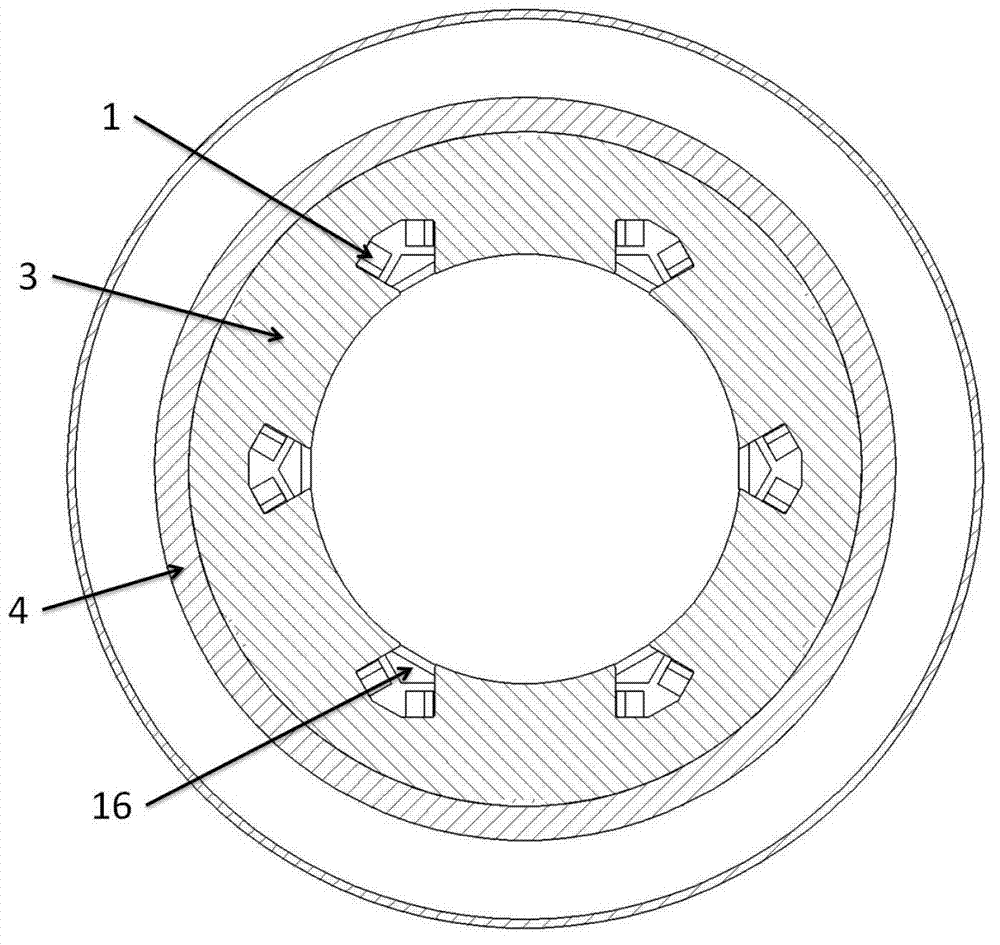

Embodiment 1

[0045] In this embodiment, the high temperature superconducting winding coil 1 is made of Bi-2223 / Ag strip material, and its shape is racetrack. The rotor 2 is a permanent magnet rotor, and the permanent magnets 19 on the rotor are NdFeB permanent magnets. The winding on the stator core adopts the fractional slot concentrated winding. The Dewar 4 is assembled with the stator core 3 by press-fitting. Stator slots are filled with stycast1266. A nonmagnetic slot wedge is inserted between the magnetic slot wedge 16 and the high temperature superconducting winding coil 1 to fix the high temperature superconducting coil. The air gap between the rotor 2 and the stator core 3 is 5mm. The stator core material is made of silicon steel sheet. Dewar 4 is a stainless steel annular Dewar with a single-layer thick-walled structure, and the inner wall of the Dewar is 12mm. The vacuum chamber 7 and the bearing seat 8 are all made of stainless steel. The Dewar 4 and the glass fiber reinfo...

Embodiment 2

[0047] In this embodiment, the high temperature superconducting winding coil 1 is made of Bi-2223 / Ag strip material, and its shape is racetrack. The rotor 2 is a rotor using a high-temperature superconducting coil as an excitation coil, and the high-temperature superconducting excitation coil 21 on the rotor is a high-temperature superconducting coil wound by a YBCO coated conductor. The winding on the stator core 3 adopts distributed winding with fractional slots. The Dewar 4 is assembled with the stator core 3 by press-fitting. Stator slots are filled with stycast1266. A nonmagnetic slot wedge is inserted between the magnetic slot wedge 16 and the high temperature superconducting winding coil 1 to fix the high temperature superconducting coil. The air gap between the rotor 2 and the stator core 3 is 10mm. The stator core material is made of non-magnetic austenitic stainless steel. Dewar 4 is a stainless steel annular Dewar with a single-layer thick-walled structure, and ...

Embodiment 3

[0049] In this embodiment, the high temperature superconducting winding coil 1 is made of Bi-2223 / Ag strip material, and its shape is a rounded rectangle. The rotor 2 is a rotor using a high-temperature superconducting block material as an excitation pole, and the high-temperature superconducting block material 23 on the rotor is a YBCO block material. The winding on the stator core 3 adopts integer slot distributed winding. The Dewar 4 is assembled with the stator core 3 by press-fitting. Stator slots are filled with stycast1266. A nonmagnetic slot wedge is inserted between the magnetic slot wedge 16 and the high temperature superconducting winding coil 1 to fix the high temperature superconducting coil. The air gap between the rotor 2 and the stator core 3 is 15mm. The stator core material is made of non-magnetic austenitic stainless steel. Dewar 4 is a stainless steel annular Dewar with a single-layer thick-walled structure, and the inner wall of the Dewar is 20mm. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com