A waste incineration fly ash treatment agent

A waste incineration fly ash and chemical treatment technology, which is applied in the field of waste incineration fly ash treatment, can solve the problems of poor treatment effect of high heavy metal fly ash, and achieve the effect of low treatment cost, price advantage, and enhanced capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A garbage incineration fly ash treatment agent, which contains the following components by weight: 20%-60% activating component (Activation), 15%-50% composite phosphate component (CompositePhosphate), 20%-50% solidified molding component ( Solidification), 1%-5% auxiliary ingredients;

[0015] The activation component (Activation) contains the following components by weight: 40%-70% Ca(OH) 2 , 20%-50% baking soda, 10%-30% baking soda;

[0016] The composite phosphate component (CompositePhosphate) contains the following components by weight: 70%-90% sodium dihydrogen phosphate or sodium phosphate, 10%-30% sodium thiosulfate;

[0017] The solidification molding component (Solidification) is Portland cement;

[0018] The auxiliary components contain the following components by weight: 20%-40% conventional dyeing agent, 60%-80% desiccant.

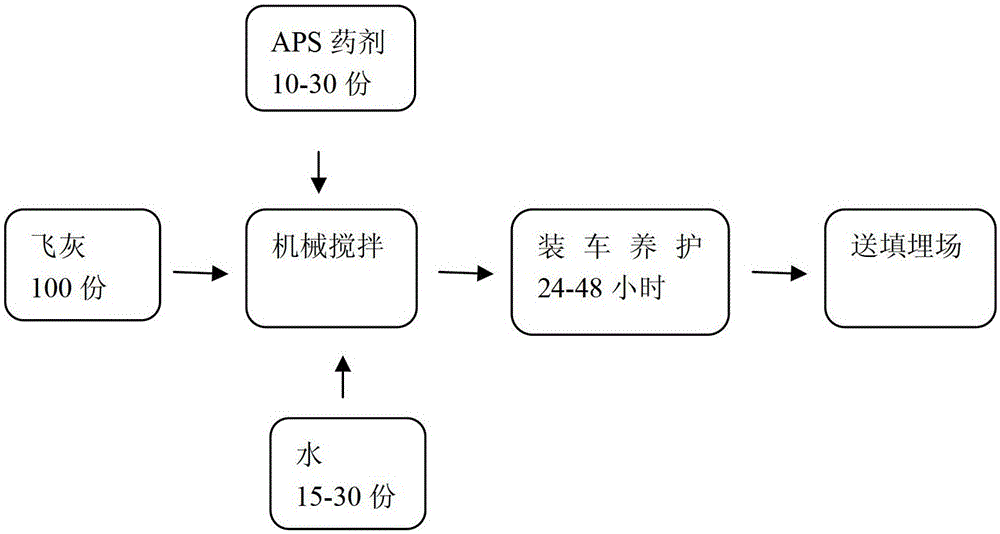

[0019] figure 1 It is a process flow chart of using the APS fly ash treatment harmless agent proposed by the present invention to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com